Preparation method of high-weather-resistance fireproof glass interlayer material

A fire-resistant glass and interlayer material technology, applied in the field of fire-resistant materials, can solve the problem that the interlayer of fire-resistant glass gel cannot suppress and eliminate bubbles in the interlayer fire-resistant glass gel, so as to improve the stability of the sol, improve the weather resistance, and improve the mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

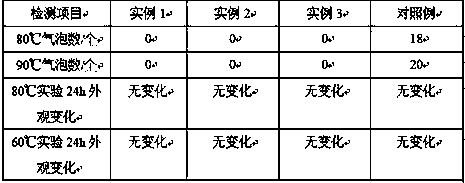

Examples

example 1

[0026] In terms of parts by weight, weigh 45 parts of anhydrous ether, 10 parts of aluminum trichloride and 25 parts of ethyl orthosilicate respectively, first take aluminum trichloride and add it to the conical flask, and add ethyl orthosilicate to In the Erlenmeyer flask, stir and mix and add anhydrous ether, magnetically stir at room temperature for 10 minutes, collect the stirred solution and place it at 100°C for 6 hours to heat and reflux to obtain a matrix gel solution; weigh 45 Put 1 part of deionized water, 10 parts of absolute ethanol, 15 parts of tetraethyl orthosilicate and 3 parts of 1mol / L hydrochloric acid in a beaker, stir and mix and let it stand for 2 hours to obtain a modified gel solution, with a volume ratio of 1:1 , stirring and mixing the modified gel solution and the matrix gel solution to obtain a mixed gel solution, respectively weighing 45 parts of trimethylchlorosilane, 55 parts of n-hexane and 10 parts of the mixed gel solution and placing them in a...

example 2

[0028] In terms of parts by weight, weigh 47 parts of anhydrous ether, 12 parts of aluminum trichloride and 27 parts of ethyl orthosilicate respectively, first take aluminum trichloride and add it to the Erlenmeyer flask, then add the ethyl orthosilicate to In the Erlenmeyer flask, stir and mix and add anhydrous diethyl ether, stir magnetically at room temperature for 12 minutes, collect the stirred solution and place it at 110°C for 7 hours under heat preservation and reflux to obtain a matrix gel solution; weigh 47 Put 1 part of deionized water, 12 parts of absolute ethanol, 17 parts of tetraethyl orthosilicate and 4 parts of 1mol / L hydrochloric acid in a beaker, stir and mix and let it stand for 2 hours to obtain a modified gel solution, with a volume ratio of 1:1 , stirring and mixing the modified gel solution and the matrix gel solution to obtain a mixed gel solution, respectively weighing 47 parts of trimethylchlorosilane, 57 parts of n-hexane and 12 parts of the mixed ge...

example 3

[0030] In terms of parts by weight, weigh 50 parts of anhydrous ether, 15 parts of aluminum trichloride and 30 parts of ethyl orthosilicate, firstly take aluminum trichloride and add it to the conical flask, then add ethyl orthosilicate to In the Erlenmeyer flask, stir to mix and add anhydrous diethyl ether, stir magnetically at room temperature for 15 minutes, collect the stirred solution and place it at 120°C for 8 hours to heat and reflux to obtain the matrix gel solution; weigh 50 Put 1 part of deionized water, 15 parts of absolute ethanol, 20 parts of tetraethyl orthosilicate and 5 parts of 1mol / L hydrochloric acid in a beaker, stir and mix and let it stand for 3 hours to obtain a modified gel solution in a volume ratio of 1:1 , stirring and mixing the modified gel solution and the matrix gel solution to obtain a mixed gel solution, respectively weighing 50 parts of trimethylchlorosilane, 60 parts of n-hexane and 15 parts of the mixed gel solution and placing them in a hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com