w-cu-sic ternary composite material and preparation method thereof

A composite material, w-cu-sic technology, applied in the field of high-density W-Cu-SiC ternary thermal control composite materials prepared by hot pressing sintering method, can solve the problem of high density of composite materials, affecting processability, and low thermal expansion coefficient and other issues, to achieve the effect of controllable density, low cost, and improved machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

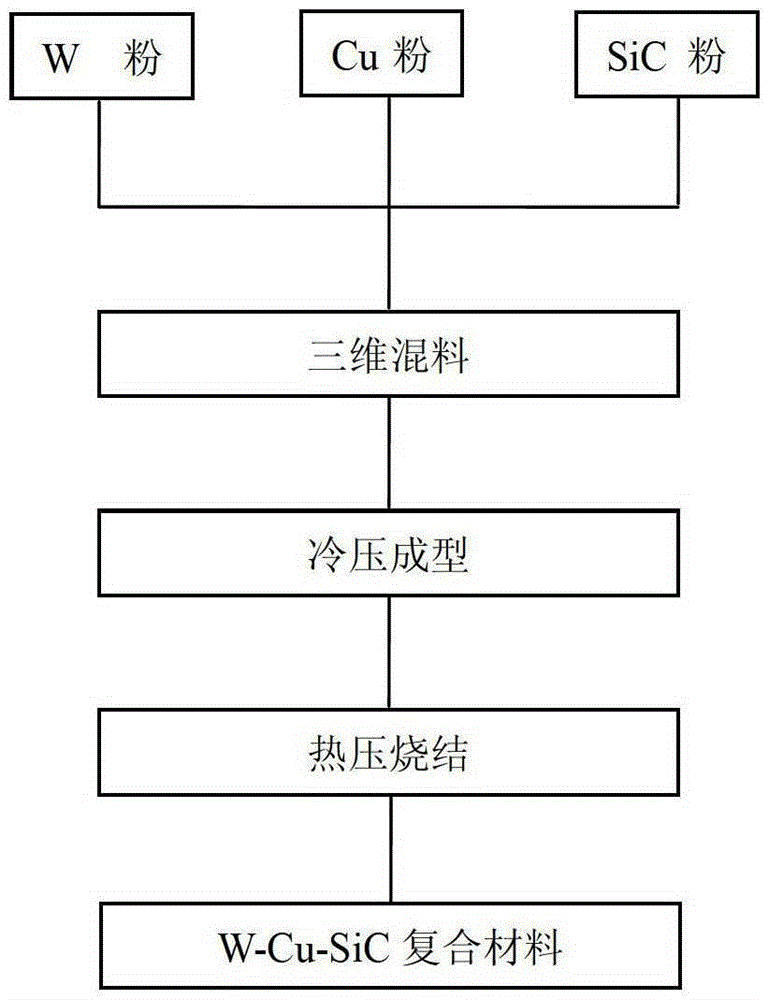

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: W-Cu-SiC ternary composite material

[0025] The content of each component is calculated by volume percentage: Cu / (W+SiC+Cu)=30~50%, SiC / (W+SiC)=20~80%, W / (W+SiC)=20~80% %.

[0026] The purity of the Cu is 99.9%, and the particle size of its powder is 1-10 μm.

[0027] The purity of the W is 99.9%, and the particle size of its powder is 10-20 μm.

[0028] The purity of the SiC is 99%, and the particle size of its powder is 10-30 μm.

Embodiment 2

[0029] Embodiment 2: W-Cu-SiC ternary composite material

[0030] The content of each component is calculated by volume percentage: Cu / (W+SiC+Cu)=30%, SiC / (W+SiC)=20%, W / (W+SiC)=80%.

[0031] Others are with embodiment 1.

Embodiment 3

[0032] Embodiment 3: W-Cu-SiC ternary composite material

[0033] The content of each component is calculated by volume percentage: Cu / (W+SiC+Cu)=50%, SiC / (W+SiC)=80%, W / (W+SiC)=20%.

[0034] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com