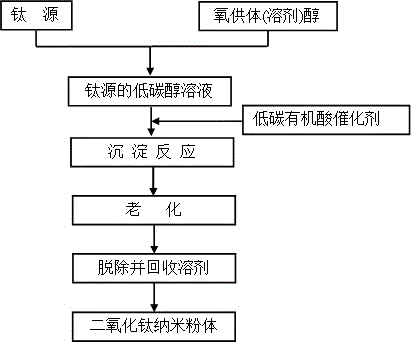

Method for preparing titanium oxide nano powder at low temperature by non-water-precipitation process

A nano-powder and titanium oxide technology, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high toxicity of raw materials, serious agglomeration of titanium oxide nano-powders, and difficult and violent reactions. Good uniformity, shortened production cycle, and improved powder quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Anhydrous ethanol is used as a solvent, butyl titanate is used as a titanium source, and anhydrous formic acid is used as a catalyst. Take 200mL of absolute ethanol and place it in a Erlenmeyer flask, add 12mL of butyl titanate, stir evenly, add 4mL of anhydrous formic acid, and then start heating in an oil bath. The slurry was aged at 80 °C for 24 h, then the solvent was removed by centrifugation and recovered, and finally the wet precipitate was dried to obtain titanium oxide nanopowder.

Embodiment 2

[0020] Anhydrous methanol is used as a solvent, ethyl titanate is used as a titanium source, and anhydrous acetic acid is used as a catalyst. Take 100mL of anhydrous methanol and place it in a conical flask, add 20mL of ethyl titanate, stir evenly, add 4mL of anhydrous acetic acid, and then start heating in an oil bath. The slurry was aged at 60 °C for 12 h, then the solvent was removed by suction filtration and recovered, and finally the wet precipitate was dried to obtain titanium oxide nanopowder.

Embodiment 3

[0022] Anhydrous isopropanol is used as solvent, isopropyl titanate is used as titanium source, and anhydrous formic acid is used as catalyst. Take 100mL of anhydrous isopropanol in a conical flask, add 4mL of isopropyl titanate, stir evenly, add 1mL of anhydrous formic acid and start heating in an oil bath, control the temperature of the oil bath to 60 °C, and the precipitation reaction is complete Finally, the precipitated slurry was aged at a temperature of 75 °C for 4 hours, and then the solvent was removed by a filter press process and recovered, and finally the wet precipitated material was dried to obtain titanium oxide nanopowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com