Production technology for controlling oxygen donor single crystal

A production process and oxygen donor technology, which is applied in the field of production process of controlling oxygen donor single crystal, can solve the problems of economic loss, increase of production cost, decrease of profit margin of single crystal sales, etc., so as to reduce the time of oxygen donor and space generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

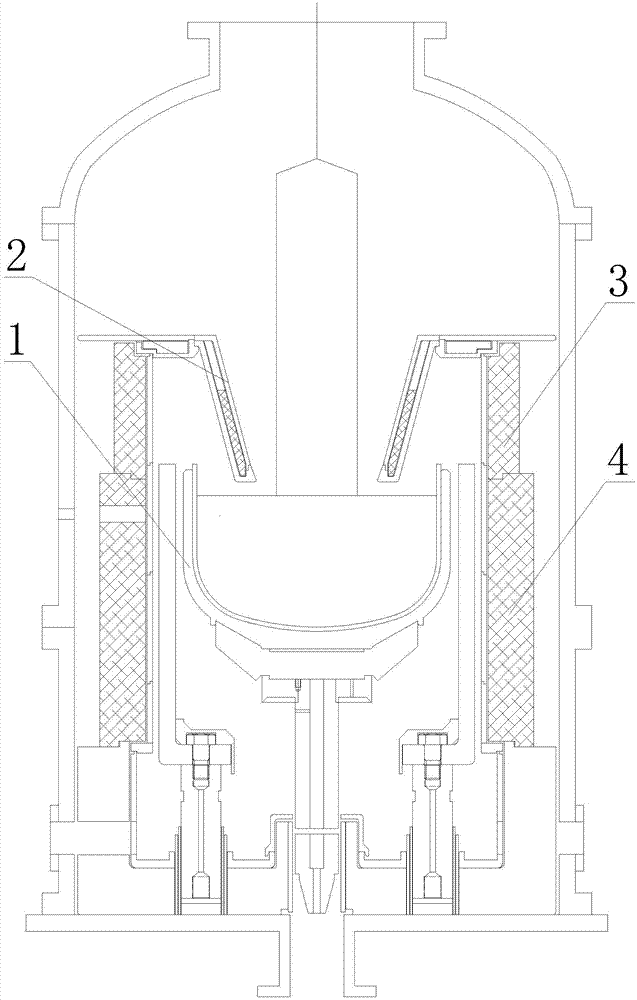

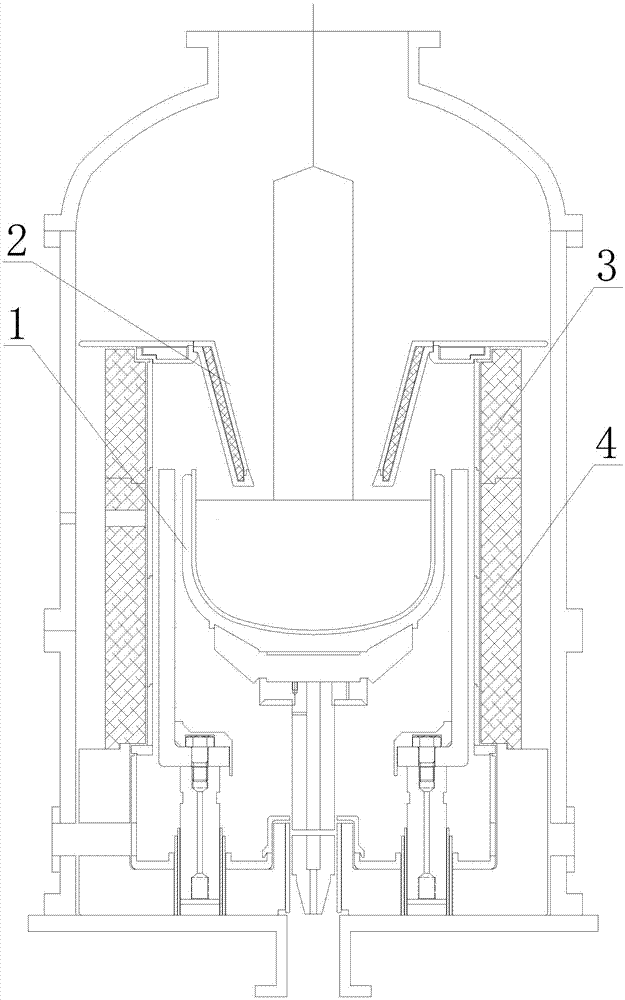

[0034] Specific embodiment 1, such as figure 1 As shown, a production process method for controlling oxygen donor single crystal, including necking step, shoulder setting step, shoulder turning step, equal diameter step, finishing step and oxygen control step, in all the above steps, the crucible in the single crystal furnace body The liquid level in 1 is always kept at a high pot position, the distance between the liquid level in the crucible 1 and the bottom of the flow guide screen 2 is 15-25mm, because the crucible will not affect the crystal formation. 1. The increase of the crucible position makes the growth rate of the single crystal faster, reduces the time that the single crystal is in the oxygen donor generation space, and achieves the purpose of reducing the oxygen donor;

[0035] In the necking step, the rotation speed of the seed crystal is 7r / min, the rotation speed of the crucible 1 is 7r / min, the rising speed of the crucible 1 is 0mm / min, and the growth speed o...

specific Embodiment 2

[0043] Specific embodiment 2, such as figure 1 As shown, a production process method for controlling oxygen donor single crystal, including necking step, shoulder setting step, shoulder turning step, equal diameter step, finishing step and oxygen control step, in all the above steps, the crucible in the single crystal furnace body The liquid level in 1 is always kept at a high pot position, the distance between the liquid level in the crucible 1 and the bottom of the flow guide screen 2 is 15-25mm, because the crucible will not affect the crystal formation. 1. The increase of the crucible position makes the growth rate of the single crystal faster, reduces the time that the single crystal is in the oxygen donor generation space, and achieves the purpose of reducing the oxygen donor;

[0044] In the necking step, the rotation speed of the seed crystal is 8r / min, the rotation speed of the crucible 1 is 9r / min, the rising speed of the crucible 1 is 0mm / min, and the growth speed o...

specific Embodiment 3

[0052] Specific embodiment 3, such as figure 1 As shown, a production process method for controlling oxygen donor single crystal, including necking step, shoulder setting step, shoulder turning step, equal diameter step, finishing step and oxygen control step, in all the above steps, the crucible in the single crystal furnace body The liquid level in 1 is always kept at a high pot position, the distance between the liquid level in the crucible 1 and the bottom of the flow guide screen 2 is 15-25mm, because the crucible will not affect the crystal formation. 1. The increase of the crucible position makes the growth rate of the single crystal faster, reduces the time that the single crystal is in the oxygen donor generation space, and achieves the purpose of reducing the oxygen donor;

[0053] In the necking step, the rotation speed of the seed crystal is 7r / min, the rotation speed of the crucible 1 is 8r / min, the rising speed of the crucible 1 is 0mm / min, and the growth speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com