Patents

Literature

56results about How to "Avoid redox reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery anode material and preparation method thereof

ActiveCN103647073AAvoid metal reductionQuick releaseElectrode thermal treatmentSecondary cellsCarbon coatingCarbon source

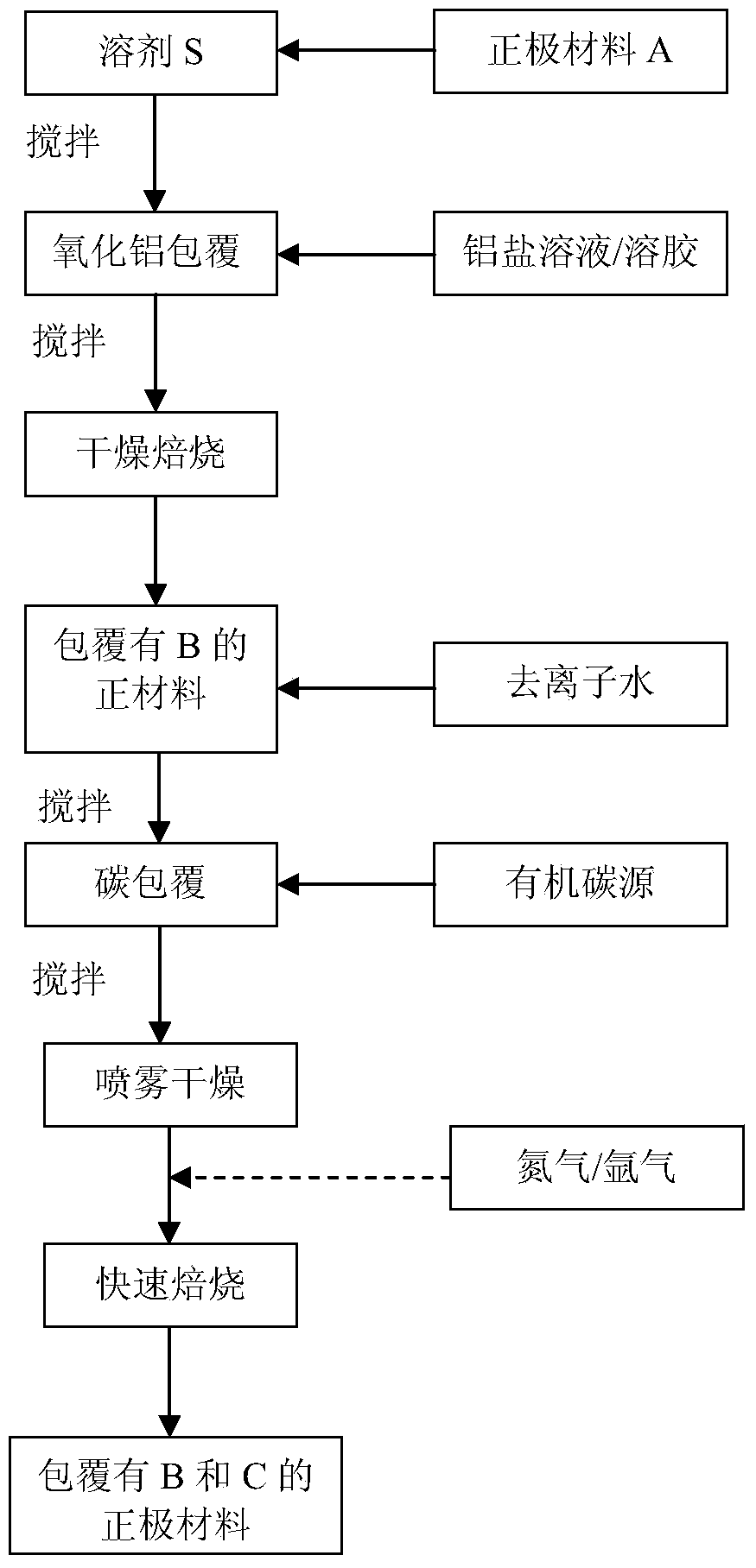

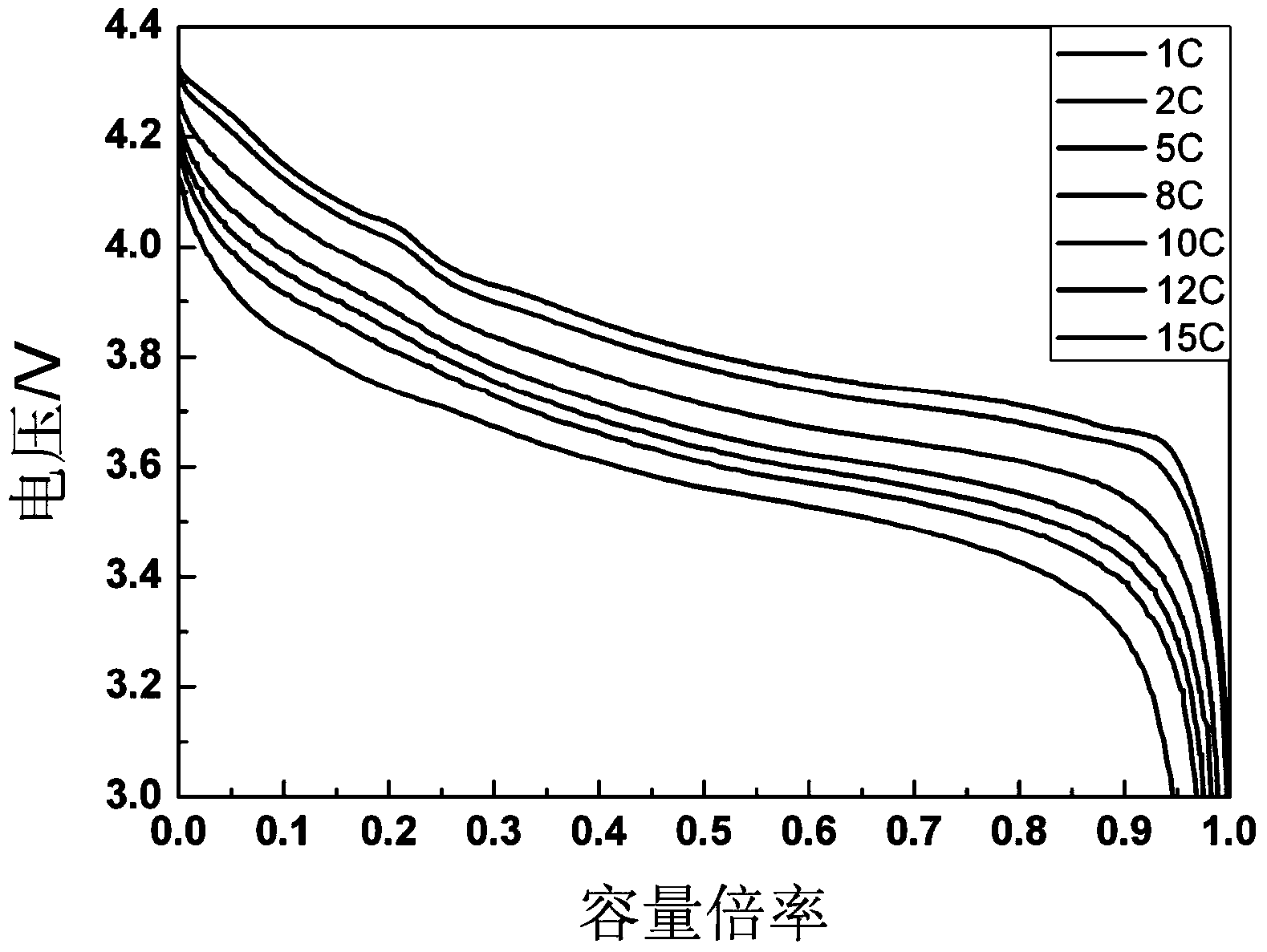

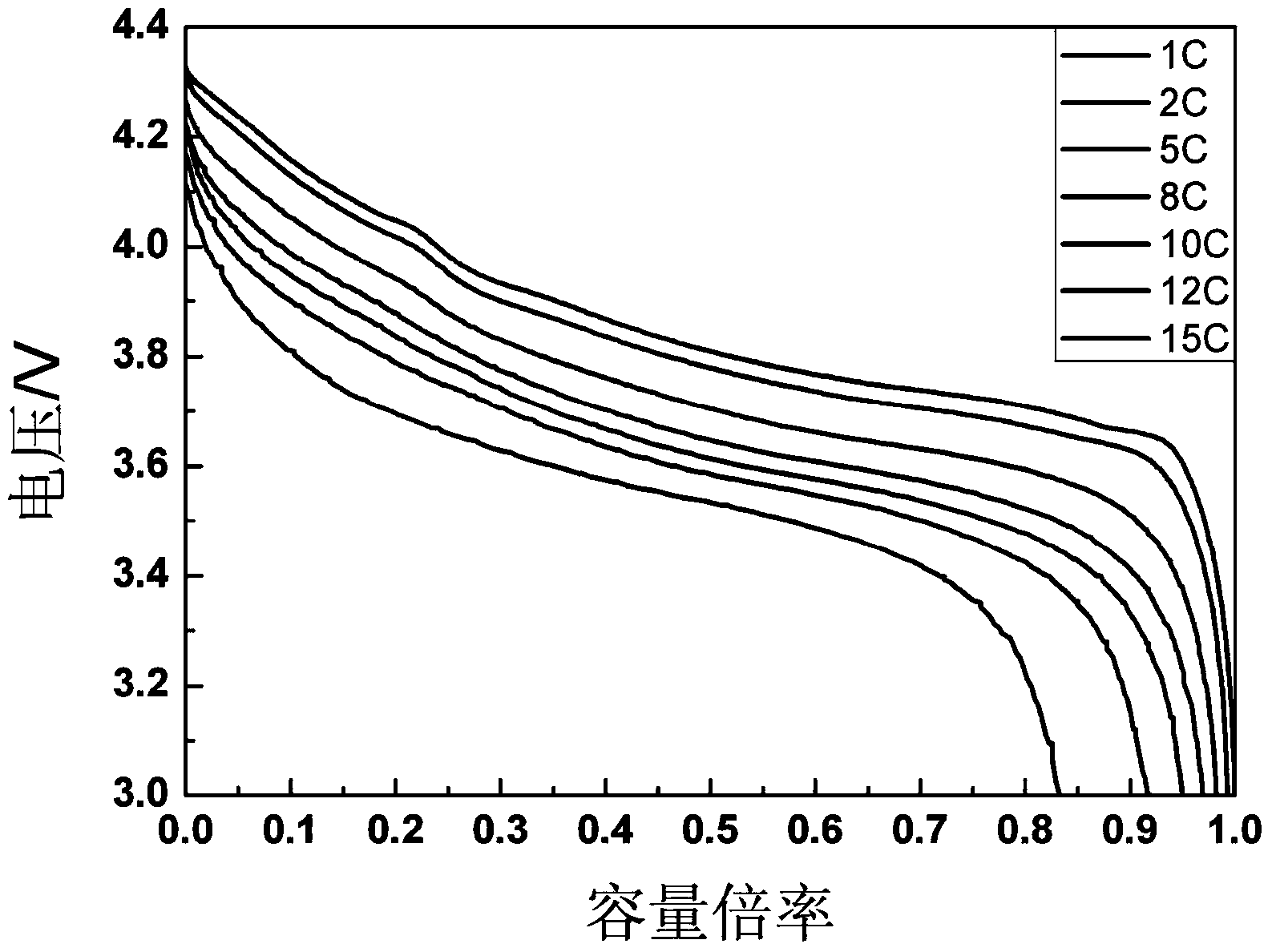

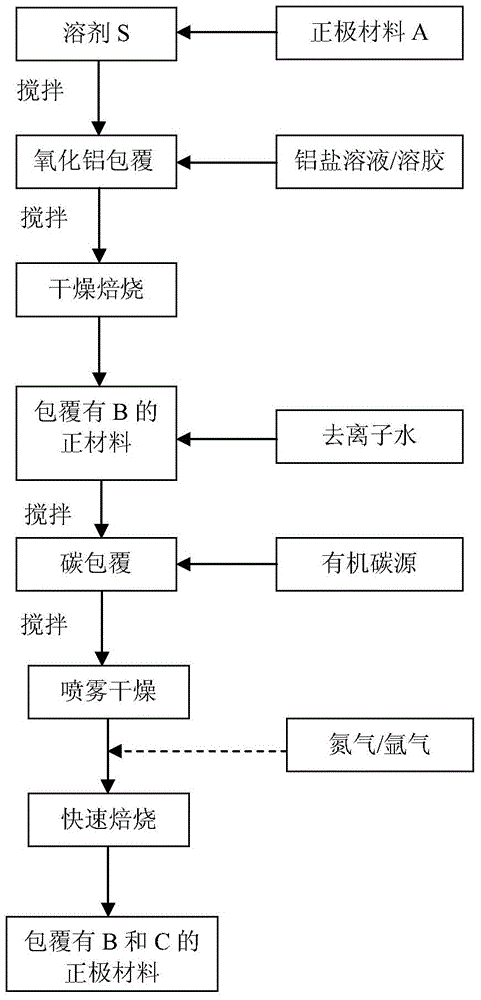

The invention discloses a preparation method of a lithium ion battery anode material. The method is characterized in that the outer surface of the existing lithium ion battery anode material is sequentially coated with an aluminum oxide layer and a carbon layer, wherein the coating condition is liquid-phase coating, in the coating process of the aluminum oxide, the addition sequence of the existing lithium ion battery anode material and aluminum salt is adjusted, and the coating substance organic aluminum salt is added under the continuously stirring condition, so that a hydrolytic product is uniformly adsorbed onto the surface of an active substance. The carbon coating is carried out through a spray drying and rapid sintering way in the inert gas atmosphere, so that the problems that the metal is reduced due to the high-temperature carbon coating and the organic carbon source is difficultly carbonized in low temperature can be avoided. The invention also discloses a lithium ion battery anode material prepared through the method. The energy density and power density of the battery can be remarkably improved, and the cycling performance, the capacity retention rate and the safety performance of the battery can be improved.

Owner:EVE ENERGY CO LTD

Aqueous lithium ion battery electrode, preparation method of electrode and aqueous lithium ion battery

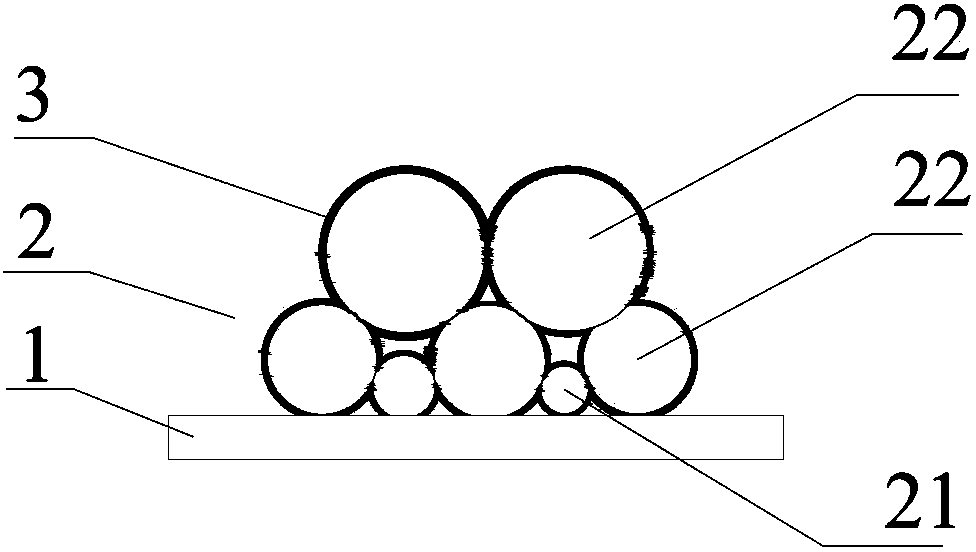

InactiveCN103904291AAvoid direct contactAvoid redox reactionsSecondary cellsActive material electrodesAqueous electrolyteOxygen evolution

The invention discloses an aqueous lithium ion battery electrode, a preparation method of the electrode and an aqueous lithium ion battery. The aqueous lithium ion battery electrode comprises a positive electrode current collector or a negative electrode current collector, a positive electrode active material layer or a negative electrode active material layer and protective layers, wherein the positive electrode active material layer is combined on the surface of the positive electrode current collector; the negative electrode active material layer is combined on the surface of the negative electrode current collector; the protective layers are combined on the surface of the positive electrode active material layer or the negative electrode active material layer and hole walls in the positive electrode active material layer and the negative electrode active material layer. Materials adopted by the protective layers are polymers containing lithium ions. Through the aqueous lithium ion battery electrode, the direct contact between the positive electrode active material layer or the negative electrode active material layer and water of an aqueous electrolyte can be prevented, so that hydrogen evolution reaction and oxygen evolution reaction of the aqueous electrolyte can be prevented, thus side reaction between active substances and water can be prevented. The aqueous lithium ion battery comprises a positive aqueous lithium ion battery electrode and a negative aqueous lithium ion battery electrode, thus giving high voltage and energy density to the aqueous lithium ion battery.

Owner:INNER MONGOLIA RUISHENG GRAPHITE NEW MATERIAL CO LTD

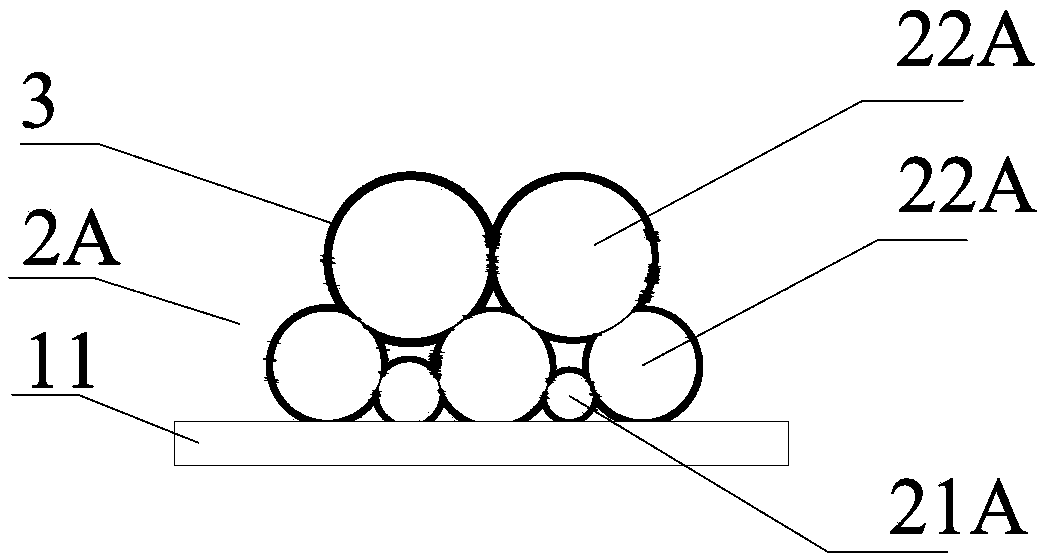

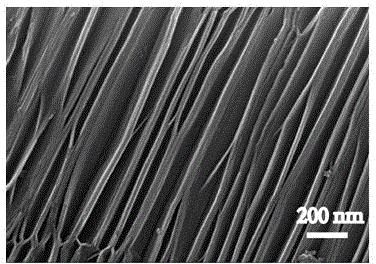

Graphene material and preparation method of electrode material of graphene material

ActiveCN104876213ASolve difficult preparationFix stability issuesCell electrodesPorous grapheneHeat conducting

The invention relates to a halide intercalated porous graphene material. The halide intercalated porous graphene material contains porous graphene sheets and a halide; the halide is intercalated between the porous graphene sheets; the particles of the halide are evenly spread between the porous graphene sheets at one single layer. The preparation method of the halide intercalated porous graphene material comprises the steps of taking a halide intercalated graphite compound as the raw materials and performing ultrasonic stripping on the raw material in a solvent to prepare the halide intercalated porous graphene material. The method is simple; the raw material is cheap and the equipment is easy to obtain; the production cost of the graphene is greatly reduced; in short, the method can be widely applied to the field of preparation of lithium-ion reversible battery electrode materials, energy source materials, conductive materials, heat-conducting materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

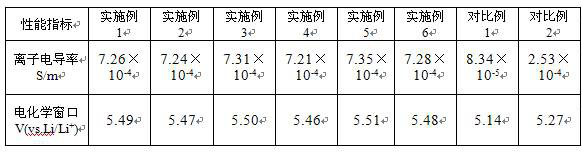

Solid electrolyte, preparation method thereof and lithium ion battery

ActiveCN106299468ALow electronic conductivityAvoid redox reactionsFinal product manufactureElectrolytesSolid state electrolyteElectrochemical window

In order to solve the problem of narrow electrochemical window of a solid electrolyte in the prior art, the invention provides a solid electrolyte. The solid electrolyte comprises a core material and a shell material, wherein the shell material wraps the core material, the core material has the following chemical formula: Li(1+x)MxTi(2-x)(PO4)3, M is selected from at least one of Al, La, Cr, Ga, Y and In, x is more than or equal to 0.05 but less than or equal to 0.4, the ionic conductivity of the shell material is over 10<-6>S / cm, and the electrochemical window of the solid electrolyte is larger than 5 volts. Meanwhile, the invention also discloses a preparation method of the abovementioned solid electrolyte and a lithium ion battery applying the solid electrolyte. The solid electrolyte provided by the invention is wide in electrochemical window and high in the ionic conductivity.

Owner:BYD CO LTD

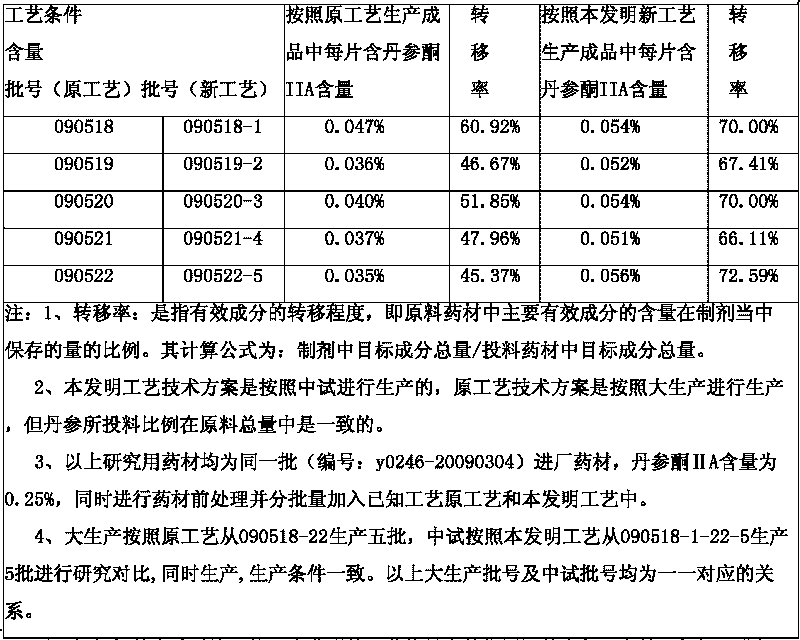

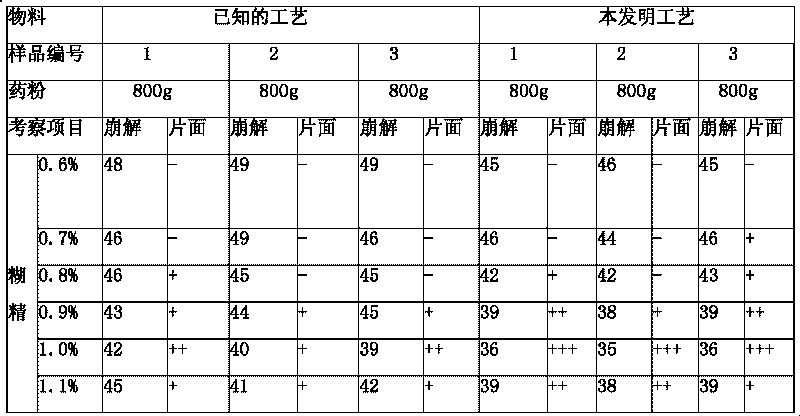

Technology for preparing compound kidney inflammation tablets

The invention relates to a technology for preparing compound kidney inflammation tablets, which is characterized in that crushing red sage roots 337.5g into fine powder, further mixing with baikal skullcap roots 202.5g, cattail pollen 112.5g and morning glory seeds 112.5g and crushing into fine powder, then sieving, furthermore, uniformly mixing motherwort fruits 450g, astragalus roots 337.5g, Siberian solomonseal rhizome 112.5g, poria cocos 202.5g, barbat skullcap 202.5g, doddor seeds 225g, gamene 112.5g, haw 337.5g, reed roots 202.5g, hizoma imperatae 225g, plantain seeds 225g, then adding water, and boiling the water for two hours through adding water by ten times at the first time, boiling for two hours through adding water by eight times at the second time, combining the boiled liquid, and filtering the boiled liquid, the filtering liquid is concentrated into thick paste whose relevant intensity is 1.35-1.39 (60 DEG C), adding the fine powder which is formed through mixing and crushing the scutellaria roots, the cattail pollen and the morning glory seeds, uniformly mixing, and drying the fine powder with 60 DEG C, crushing into fine powder (passing through a 100-eyes screen), lastly adding crushed red sage root fine powder and 1.0% dextrin, uniformly mixing, preparing into granules by 85% ethanol, drying with the temperature of DEG C, namely obtaining one thousand tablets. The compound kidney inflammation tablets produced by the technology have high effective component and good healing efficacy.

Owner:HENGSHENGTANG PHARMA XIAN CITY

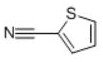

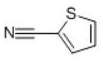

Lithium ion battery electrolyte capable of improving positive and negative electrode film formation

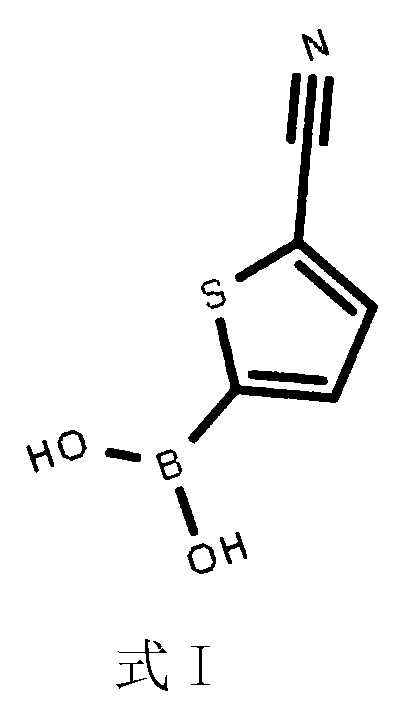

ActiveCN111313092APromote dissolutionDissolution inhibitionFinal product manufactureSecondary cells servicing/maintenancePropanoic acidMethyl carbonate

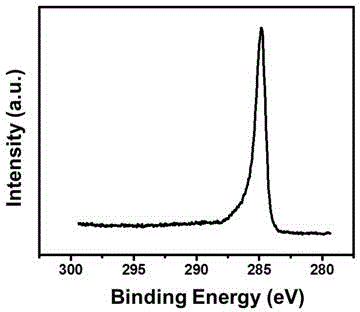

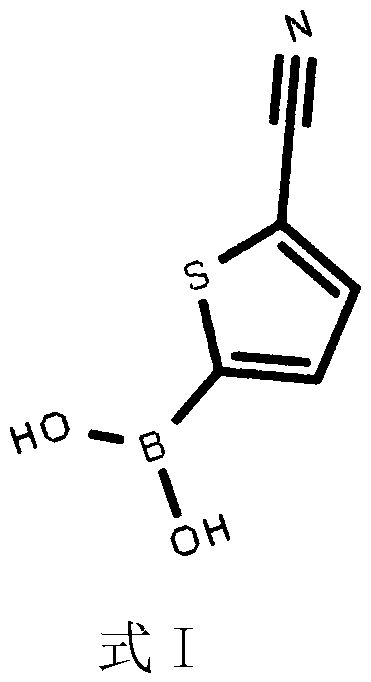

The invention relates to a lithium ion battery electrolyte capable of improving positive and negative electrode film formation. The electrolyte comprises a non-aqueous organic solvent, a lithium saltand an additive, wherein the additive is 5-cyanothiophene-2-boric acid, the mass fraction of the 5-cyanothiophene-2-boric acid in the battery electrolyte is 0.5-3 percent, the mass fraction of the 5-cyanothiophene-2-boric acid in the battery electrolyte is 1-25, the non-aqueous organic solvent is the combination of at least two of dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, methyl formate, methyl acetate, methyl propionate, ethyl acetate, 1, 3-propane sultone, adiponitrile, succinonitrile, ethylene carbonate and propylene carbonate. There are two lithium salts, one lithium salt is lithium hexafluorophosphate with the molar concentration of 1 mol / L, and the other lithium salt is one of lithium difluorophosphate, lithium difluoroborate, lithium tetrafluoroborate and lithium bis (oxalato) borate. The lithium ion battery electrolyte has the advantages that the film forming performance of the lithium ion battery electrolyte on the surfaces of the positive and negative electrode materials is remarkably improved, and the cycle performance of the lithium ion battery under high voltage is improved.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

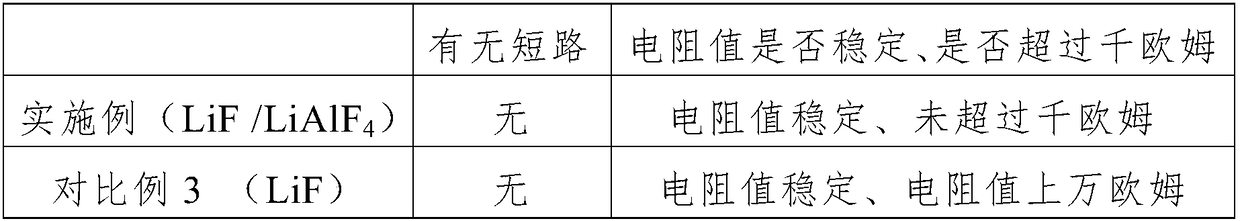

Anode and preparation method thereof, lithium battery

ActiveCN109148826AInhibit growthImprove securitySecondary cellsVapour deposition manufacturingSputteringNickel–lithium battery

The invention relates to a negative electrode and a preparation method thereof, and a lithium battery comprising the negative electrode. The negative electrode according to the invention comprises a lithium negative electrode sheet; A LiF layer deposited on at least one side of the lithium negative electrode sheet; A LiAlF4 layer deposited on the LiF layer. The lithium battery of the present invention includes a negative electrode of the present invention. The preparation method of the negative electrode of the invention comprises the following steps: providing a lithium negative electrode sheet; Depositing a LiF layer on at least one side of a lithium negative electrode sheet by a magnetron sputtering method; LiAlF4 layer was deposited on LiF layer by magnetron sputtering, and lithium anode was obtained. According to the negative electrode of the invention, the growth of the lithium dendrite can be prevented, thereby ensuring the safety performance of the lithium battery including thenegative electrode of the invention; The lithium battery including the negative electrode of the present invention can also be guaranteed to have good lithium ion conductivity. The preparation methodof the invention does not discharge fluorine gas, has no special requirements for the material of the reaction vessel or the equipment, and ensures the stability of the lithium negative electrode sheet, the LiF layer and the LiAlF4 layer.

Owner:桑德新能源技术开发有限公司 +1

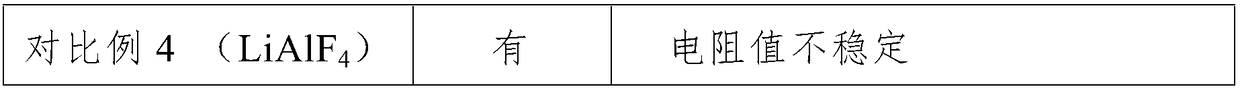

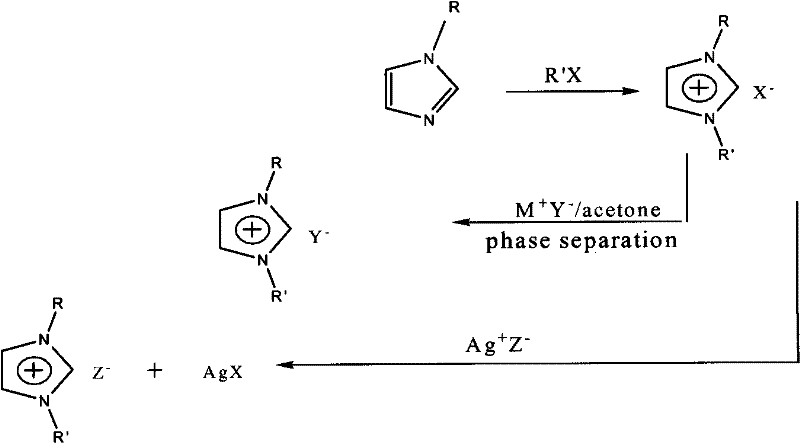

Method for synthesizing organic ionic compounds

InactiveCN102199096ALow residual moistureAvoid hydrolysisSulfonic acids salts preparationAmino preparation by functional substitutionQuaternary ammonium cationProton

The invention discloses a method for synthesizing organic ionic compounds. The method is a two-step method comprising the steps of: first, amine or a heterocyclic compound containing N element is subject to a reaction with a matter which can provide protons, such that an amine salt or a heterocyclic onium salt is produced; second, the obtained amine salt or heterocyclic onium salt is subject to a reaction with carbonate, such that a corresponding quaternary ammonium salt or an N- substituted heterocyclic onium salt is produced. The organic ionic compound is a salt comprising one of the following anions: BF4<->, PF6<->, ClO4<->, CF3SO3<->, C4F9SO3<->, [(CF3SO2)2N] <->, [(C2F5SO2)2N] <->, [B(COOCOO)2] <->, [(CN)2N] <->, BF2(CF3)2<->, BF(CF3)3<->, PF3(C2F5)3<->, and PF3(CF3)3<->. After a reaction is carried out between an acid solution and amine or a heterocyclic compound containing N element, water is removed through heating, vaporizing or distilling, such that the ammonium salt or the heterocyclic onium salt with little water content is obtained. The first step of the method assists in controlling the acid concentration of the reaction system, such that the reaction efficiency can be improved. After the first-step reaction, water residual contents in the ammonium salt or the heterocyclic onium salt can be minimized, such that possibilities of side reactions can be reduced.

Owner:邱建兴

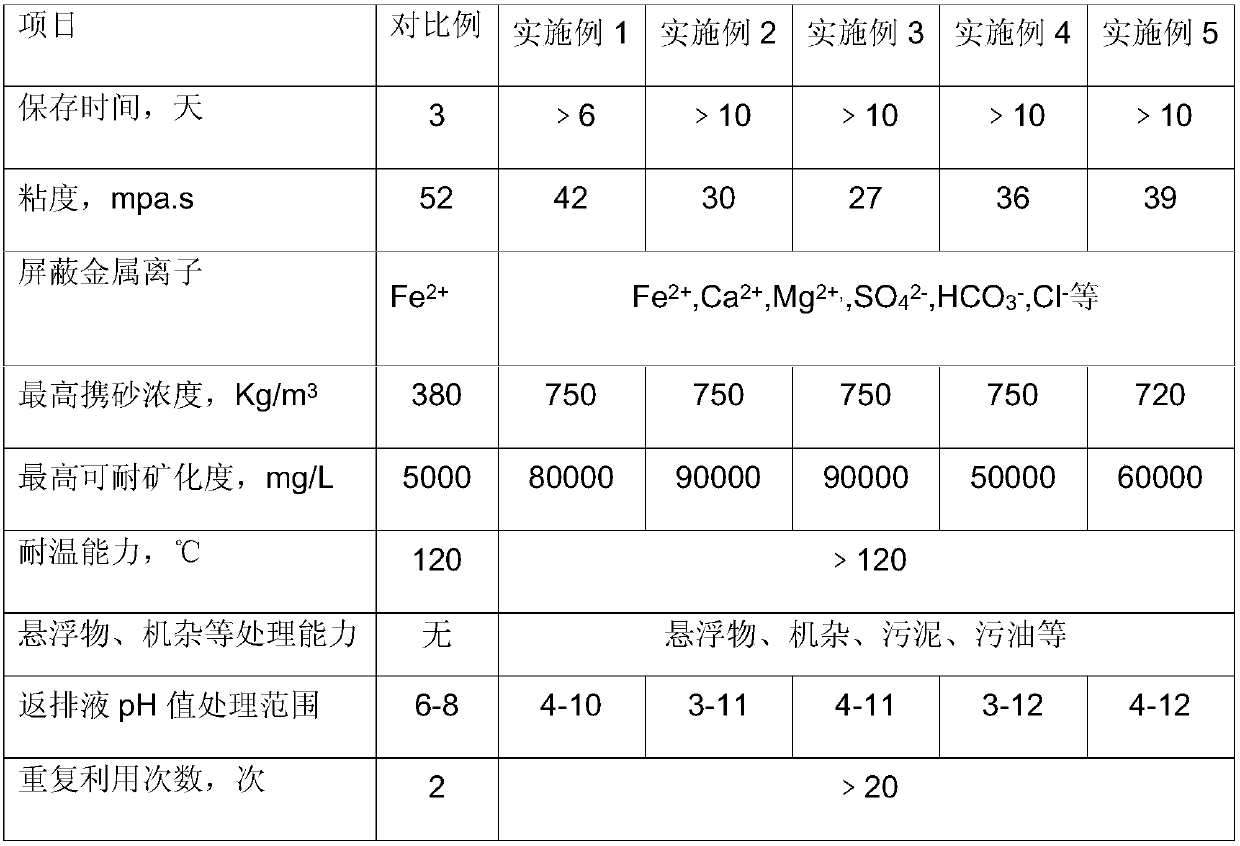

Method for directly recycling and reusing fracturing flow-back fluid

The invention discloses a method for directly recycling and reusing a fracturing flow-back fluid. The method comprises the following steps that settling and sand removing are carried out, wherein a settling tank is used for removing a propping agent and mechanical impurities in a fracturing flow-back fluid, and then the treated fracturing flow-back fluid is poured into a tank for storage; sterilization and preservation are carried out, wherein a bactericide is added into a liquid storage tank for inhibiting bacterial reproduction; flocculating and shielding are carried out, wherein a flocculating shielding agent is added before liquid preparation for shielding metal high-valence ions; the pH value is adjusted for facilitating the tackifying of a thickening agent under a weak acidic condition; then additives such as the thickening agent, a discharge aiding agent, a clay stabilizer and the like are sequentially added according to a design formula; circulation is carried out for 5-10min for forming a base solution; a cross-linking agent is added in a construction process for forming a gel; a gel breaker is added in a construction last period; after fracturing is completed, a well is closed for discharging; and the fracturing flow-back liquid is recycled and utilized repeatedly and circularly. According to the treatment method, the safety and environmental protection pressure caused by large-scale fracturing of oil fields can be effectively relieved, water resources are saved, and the economic benefits and social benefits are remarkable.

Owner:PETROCHINA CO LTD

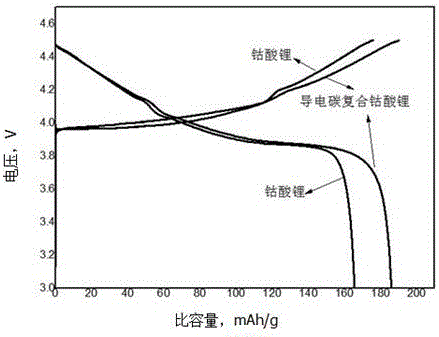

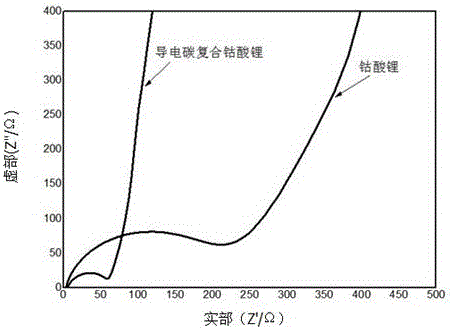

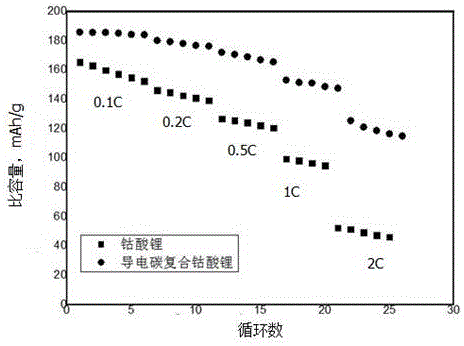

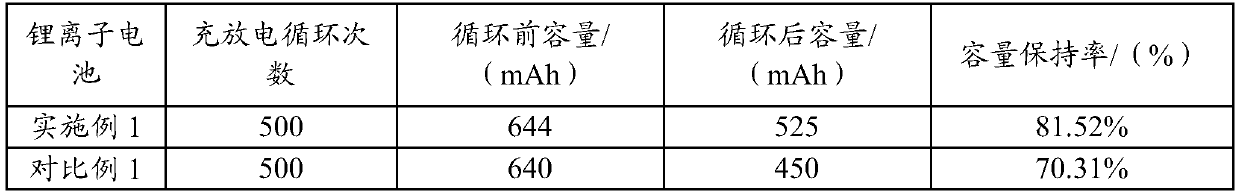

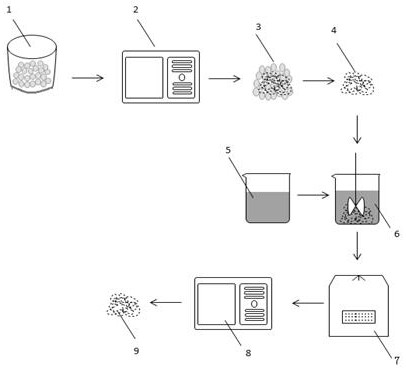

Preparation method of carbon composite metal lithium oxide anode material

ActiveCN106299300AImprove conductivityStrong process adaptabilityCell electrodesCarbon compositesLithium oxide

The invention discloses a preparation method of a carbon composite metal lithium oxide anode material. The method comprises the following steps: (1) weighing a metallic oxide and a lithium salt according to a molar ratio, mixing the metallic oxide and the lithium salt, and performing heating and sintering to obtain a metal lithium oxide anode material powder; (2) weighing a carbon source whose weight is 0.01-10% that of the powder, dispersing the carbon source into an oxidizing agent, and performing oxidization, filtration and washing to obtain a surface functionalized carbon source precursor suspension liquid; (3) adding the metal lithium oxide anode material powder into the functionalized carbon source precursor suspension liquid while stirring, stirring evenly for reaction for 5 hours, and obtaining a carbon composite metal lithium oxide precursor powder; (4) thermally treating the precursor powder under an inert gas to obtain the carbon composite metal lithium oxide anode material. The carbon composite metal lithium oxide anode material has a relatively high specific charge-discharge capacity, and the first specific discharge capacity is up to 190mAh / g; the internal resistance is reduced, so that the cycle performance and the rate capability are better.

Owner:SHANGHAI UNIV

Reagent composition and method for preserving integrity of nucleic acid in human saliva

ActiveCN111378719AAvoid degradationProtect from mechanical damageMicrobiological testing/measurementBenzoic acidSaliva sample

The present invention provides a reagent composition and method for preserving the integrity of nucleic acid in human saliva and an application of the kit composition. The reagent composition comprises urea, sodium lauryl sulfate, trans-1, CDTA, Tris-HCl, sodium ascorbate, propyl p-hydroxybenzoate, diazolidinyl urea, ethanol, sucrose and protease K. The reagent composition and the human saliva aremixed uniformly and then are stored at the normal temperature. The reagent composition and the preservation method can inhibit the nuclease activity and protect nuclease from being contaminated withexternal microorganisms or being oxidized, thereby ensuring the purity and integrity of genomic DNA; and the preservation time is long, the applicable storage temperature range is wide, and the stability of a saliva sample in a process of transportation among acquisition places can be ensured.

Owner:HANGZHOU KMB BIOTECH

Electrolyte and lithium ion battery

ActiveCN111162315ALow melting pointImprove high temperature stabilitySecondary cellsComposite electrolytesPropanoic acidHigh energy

The invention relates to the field of lithium ion batteries, and discloses an electrolyte which comprises a high-temperature organic solvent, a positive and negative electrode protection additive andan electrolyte lithium salt, wherein the high-temperature organic solvent comprises the following components in parts by weight of 5-30 parts of ethylene carbonate, 5-30 parts of propylene carbonate,5-30 parts of diethyl carbonate, 5-50 parts of propyl propionate and 1-10 parts of fluorobenzene; the positive and negative electrode protection additive comprises the following components in parts byweight of 0.2 to 5 parts of ethylene sulfate, 0.2 to 5 parts of fluoroethylene carbonate, 0.2 to 5 parts of difluoroethylene carbonate, 0.2 to 5 parts of a dinitrile organic matter, 0.2 to 3 parts oflithium difluorophosphate, 0.2 to 5 parts of diethylene glycol dipropionitrile ether, 0.2 to 3 parts of lithium fluorosulfonyl imide, 0.1 to 2 parts of 1-propyl phosphoric anhydride, 0.5 to 20 partsof 1, 1, 2, 2-tetrafluoroethyl-2, 2, 3, 3-tetrafluoropropyl ether, 0.1 to 2 parts of lithium oxalyldifluoroborate and 0.1 to 1 part of methylene methanedisulfonate. The electrolyte is excellent in high-temperature resistance, enables the lithium ion battery with high energy density to normally work at the temperature of 70 DEG C or above, and can keep the relatively better endurance.

Owner:EVE ENERGY CO LTD

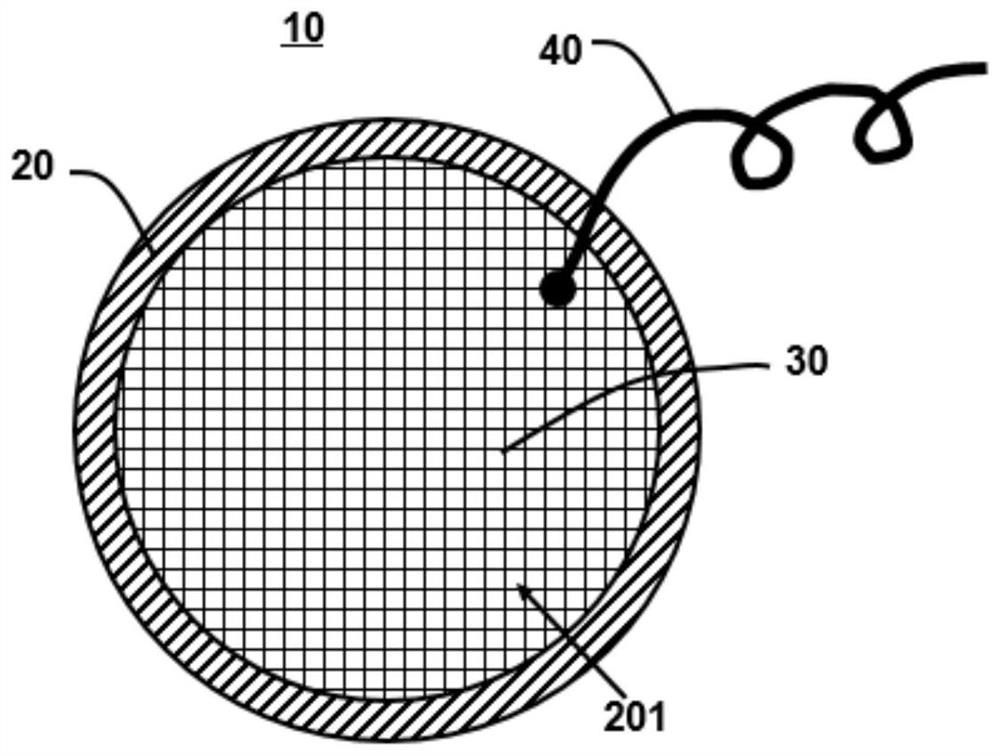

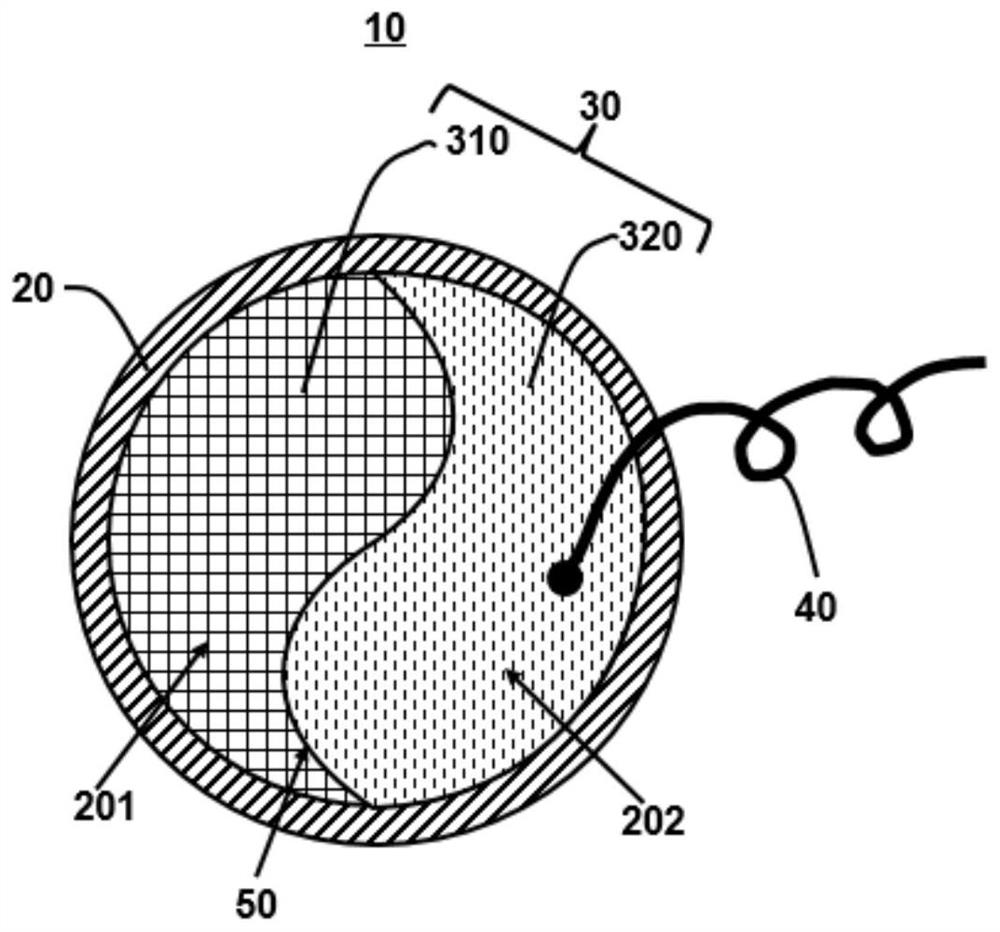

Lithium ion solid electrolyte with core-shell structure and preparation method

InactiveCN112582682AGood effectAvoid redox reactionsMagnetic/electric field screeningFinal product manufactureSolid state electrolytePhysical chemistry

The invention relates to the field of lithium batteries, and discloses a lithium ion solid electrolyte with a core-shell structure and a preparation method. The preparation method comprises the following steps of (1) mixing Li2CO3, Al2O3, TiO2 and NH4H2PO4, calcining, cooling, grinding and sieving to obtain core layer powder; (2) adding LiOH H2O, H3BO3, NH4H2PO4 and NH4F into deionized water, uniformly stirring, adjusting the pH value, adding silica sol, and mechanically stirring to obtain sol; and (3) adding the core layer powder and Al (H2PO4) 3 into the sol, carrying out spray drying, sintering the obtained precursor material, cooling, grinding, washing, and drying to obtain the lithium ion solid electrolyte with the core-shell structure. Compared with a common inorganic solid electrolyte, the inorganic solid electrolyte with the core-shell structure has the advantages that a complete and compact electron shielding layer is formed on the surface of a base material, so that an electrochemical window is wide, the ionic conductivity is high, and the application prospect is good.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

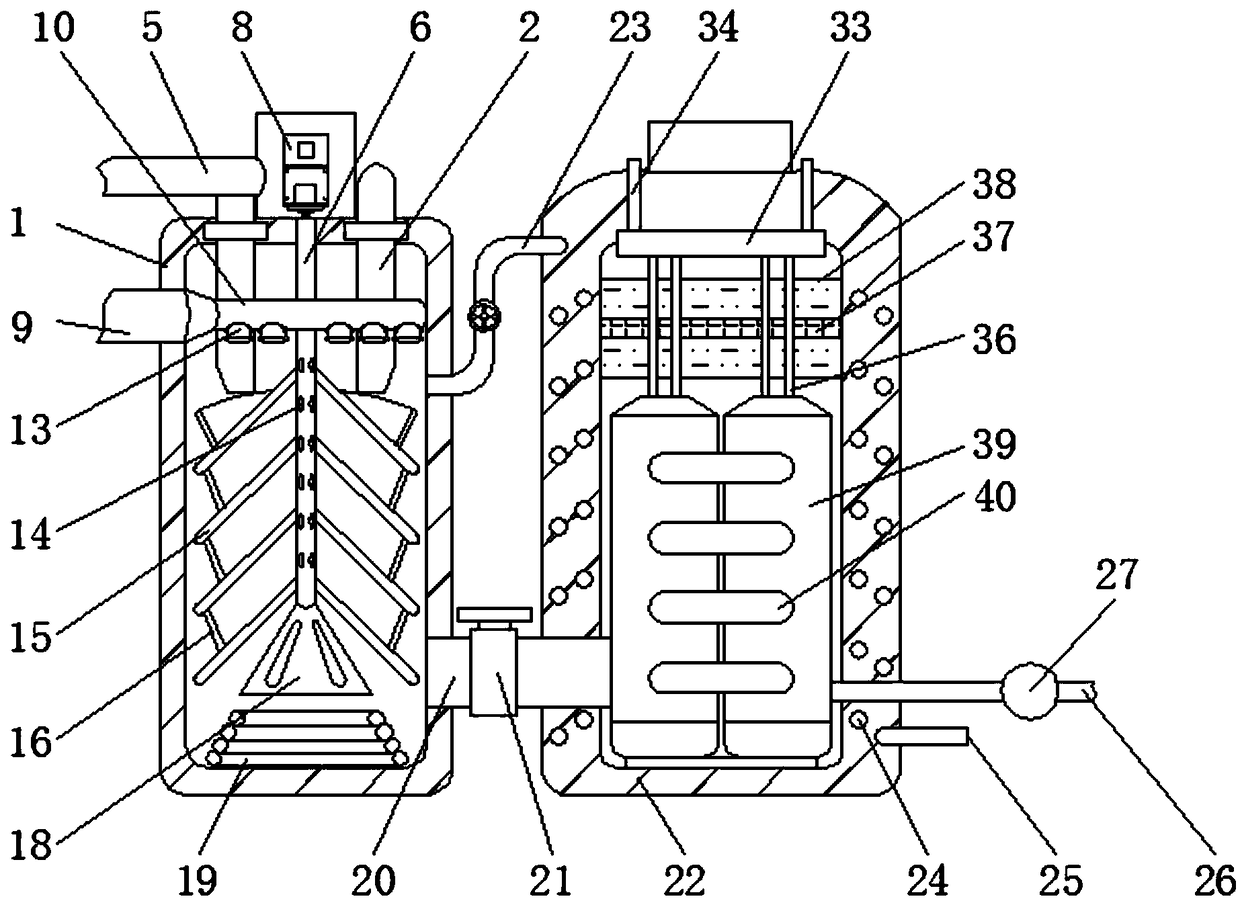

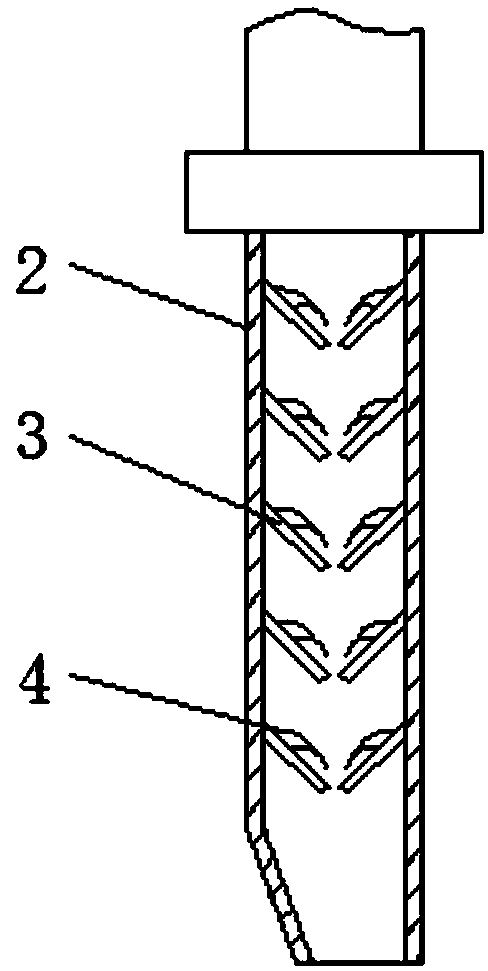

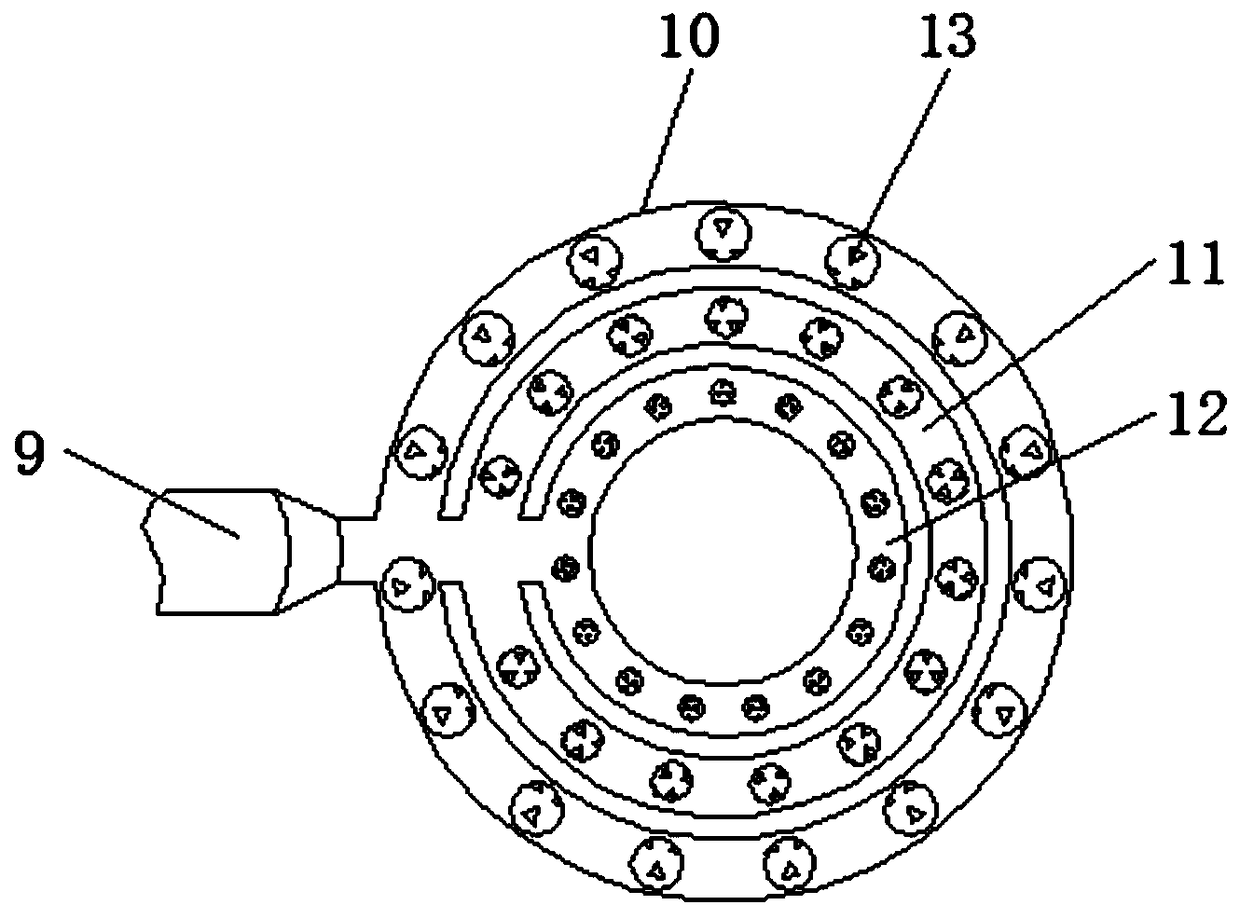

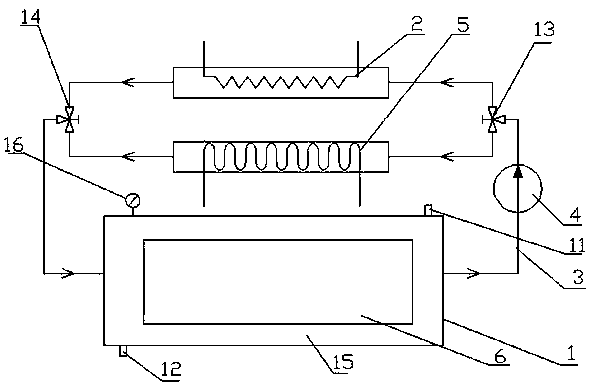

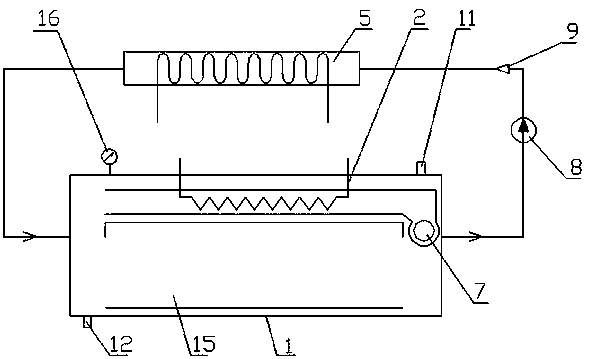

Caustic soda recycling device for chemical machinery

InactiveCN109173941AExpand the scope of joiningAdd control goodAlkali metal hydroxidesChemical/physical processesChemical reactionRaw material

The invention discloses a caustic soda recycling device for chemical machinery. The caustic soda recycling device comprises a first tank body and a second tank body, wherein a feed pipe is arranged inside the first tank body; another feed pipe is fixed above the feed pipe; an auxiliary material pipe penetrates through the inner wall of the left side of the first tank body; a heating ring is arranged at the bottom of the interior of the first tank body, and a through pipe penetrates through the lower side of the right wall of the first tank body; a valve is arranged on the outer side of the through pipe; a partition plate is fixed on the inner wall of the second tank body; and the second tank body is positioned on the right side of the through pipe. According to the caustic soda recycling device for chemical machinery, due to the arrangement of the feed pipe, raw materials containing caustic soda can be smoothly added into the first tank body, and the materials are uniformly dispersed due to an inclined plate and a semicircular mesh arranged in the feed pipe, so that the materials are scattered; chemical reaction additives are introduced into the auxiliary material pipe and are usedfor reducing and purifying the caustic soda; and due to the arrangement of a first ring pipe, a second ring pipe and a third ring pipe, the addition range area of the additives is enlarged.

Owner:戴聪聪

Precursor solution of copper-zinc-tin-sulfur thin film solar cell as well as preparation method and application thereof

ActiveCN111554760AQuality improvementImprove stabilityFinal product manufactureVacuum evaporation coatingThin film morphologyElectrical battery

The invention discloses a precursor solution of a copper-zinc-tin-sulfur thin film solar cell as well as a preparation method and application thereof. The invention discloses two types of simple metalcomplexes capable of preparing a high-quality precursor solution. By utilizing the metal complexes as precursor compounds, the prepared precursor solution is good in stability and can be used for preparing a copper-zinc-tin-sulfur thin film light absorption material which is high in crystallization quality, good in thin film morphology and free of an impurity phase, and a copper-zinc-tin-sulfur thin film solar cell prepared from the copper-zinc-tin-sulfur thin film light absorption material is high in photoelectric conversion efficiency. By using the metal complexes, the preparation process of the precursor solution is simplified, the quality of the precursor solution is improved, the energy conversion efficiency of a photovoltaic device is improved, and the precursor solution has a greatindustrial application potential.

Owner:NANJING UNIV OF POSTS & TELECOMM

Instant tea capsule and preparation method thereof

The present invention discloses an instant tea capsule, which comprises a tea concentrate and a capsule shell according to a mass ratio of the tea concentrate to the capsule shell of 70:30, wherein the tea capsule shell comprises, by weight, 70-80% of glutinous rice starch, 5-10% of an organic acid, and 10-20% of sodium bicarbonate, and the tea concentrate is screened with a 80-100 mesh sieve. According to the present invention, the tea concentrate retains most of the water-soluble components of the tea raw leaf, wherein the sodium bicarbonate and the organic acid in the capsule shell can be quickly subjected to the effervescent reaction and the produced gas bubbles are attached to the tea concentrate powder after the instant tea capsule is put into the infusion container and the capsule shell contacts the water, such that the tea concentrate can be promoted to be rapidly dispersed and dissolved so as to form the clarified and uniform tea beverage, wherein the tea aroma is rich; and the instant tea capsule has characteristics of easy carrying and easy infusion, can achieve the infusion with room temperature water, has advantages of rapid disintegration and rapid dissolution, and can achieve the good taste tea beverage.

Owner:何宗儒

Pulsed power source for medium-speed WEDM smoothness machining and machining method of pulsed power source

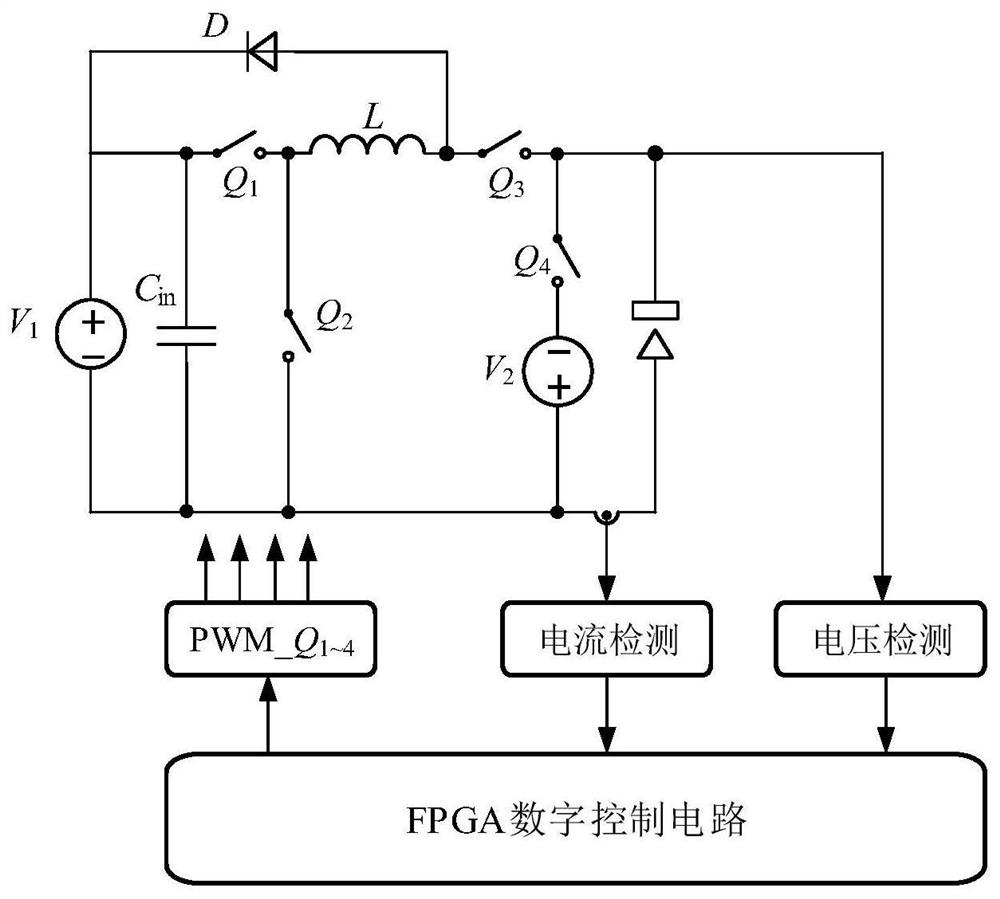

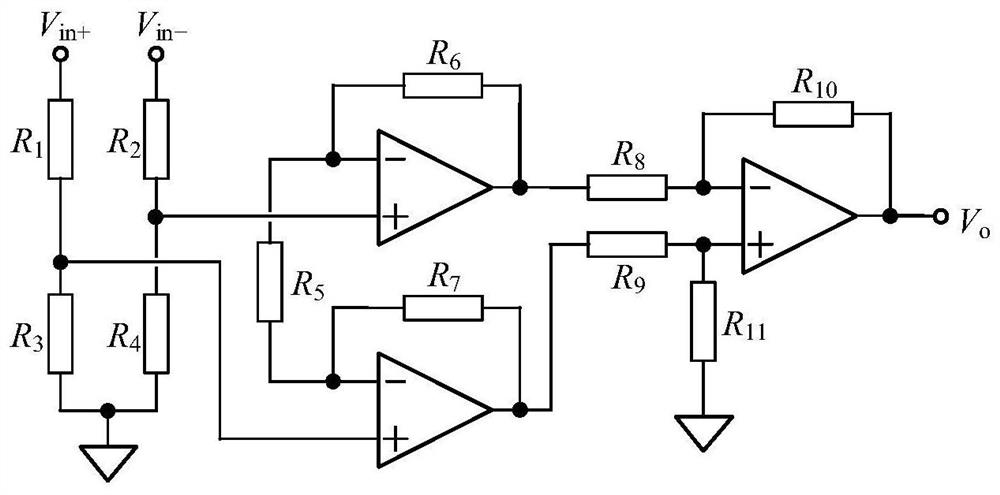

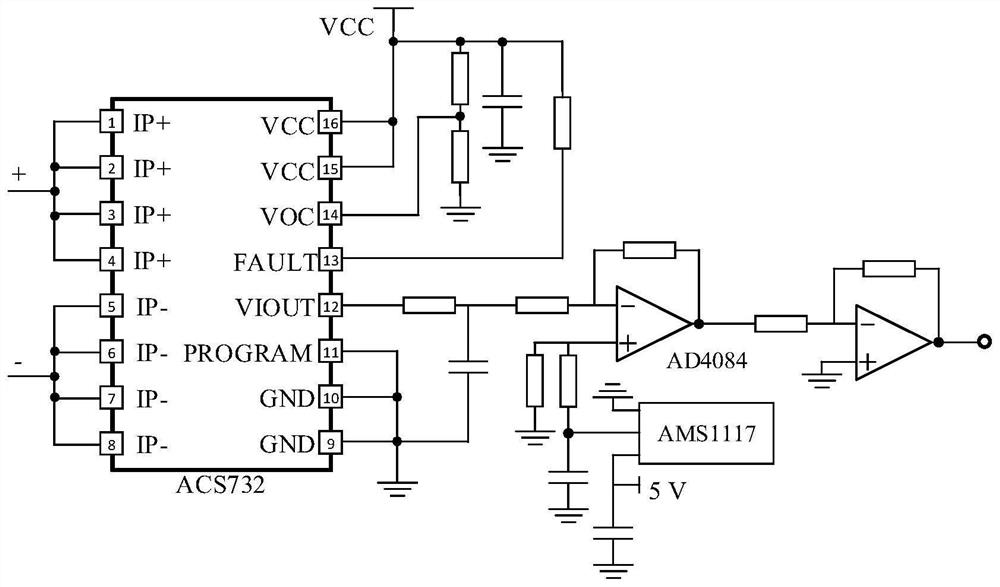

ActiveCN111644718AImprove efficiencyFast chargingEfficient power electronics conversionElectric circuitsElectrolysisHemt circuits

The invention discloses a pulsed power source for medium-speed WEDM smoothness machining. The pulsed power source comprises a main power circuit, a voltage detection circuit, a current detection circuit and an FPGA digital control circuit. The main power circuit is used for charging a gap and providing discharge energy of three times of machining. The current detection circuit and the voltage detection circuit are used for detecting current and voltage signals of the gap in the machining process of three tools in real time. The FPGA digital control circuit is used for generating a PWM signal according to the real-time gap voltage and current signals, on and off of a switching pipe in the main power circuit are controlled, and for electrolysis prevention between discharge pulses of each time of machining, on the premise of gap breakdown, the discharge energy of the third tool is reduced to the lowest. The smoothness of the surface of a workpiece is guaranteed, and the machining qualityof the power source to the surface of the workpiece is improved.

Owner:NANJING UNIV OF SCI & TECH

Product for replenishing nutrient elements necessary for human bodies and preparation method thereof

InactiveCN103720698AImprove physical functionImprove the activation effectHeavy metal active ingredientsHydroxy compound active ingredientsConvulsionNutritional deficiency

The invention relates to the technical field of medicines and health-care products, and in particular relates to a product for replenishing nutrient elements necessary for human bodies and a preparation method thereof. The product for replenishing nutrient elements necessary for human bodies comprises 0.1-50 parts by weight of gamma-aminobutyric acid, 5-70 parts by weight of vitamins and auxiliary materials, and 5-50 parts by weight of minerals. The vitamins and the gamma-aminobutyric acid are mixed with mineral raw materials respectively, pelletized, dried, cooled and granulated into products such as granules, tablets and capsules. By using the product for replenishing nutrient elements necessary for human bodies related to the invention, the nutritional deficiency of other multi-vitamin mineral tablets is replenished, and the physiological functions of human bodies can be improved effectively. Components are blended in a proper ratio, so that the physiological effects of sedating, hypnotizing, resisting convulsion, lowering blood pressure and the like can be achieved, the activity of brain can be promoted effectively, the stress is relieved, the sleep is improved, beautifying and skin-moistening functions are realized, the brain ageing function is relayed, and a good blood pressure lowering effect is achieved. Meanwhile, the kidney function can be improved and protected, and fatty liver and obesity are suppressed.

Owner:YUNNAN LONGRUN PHARMA

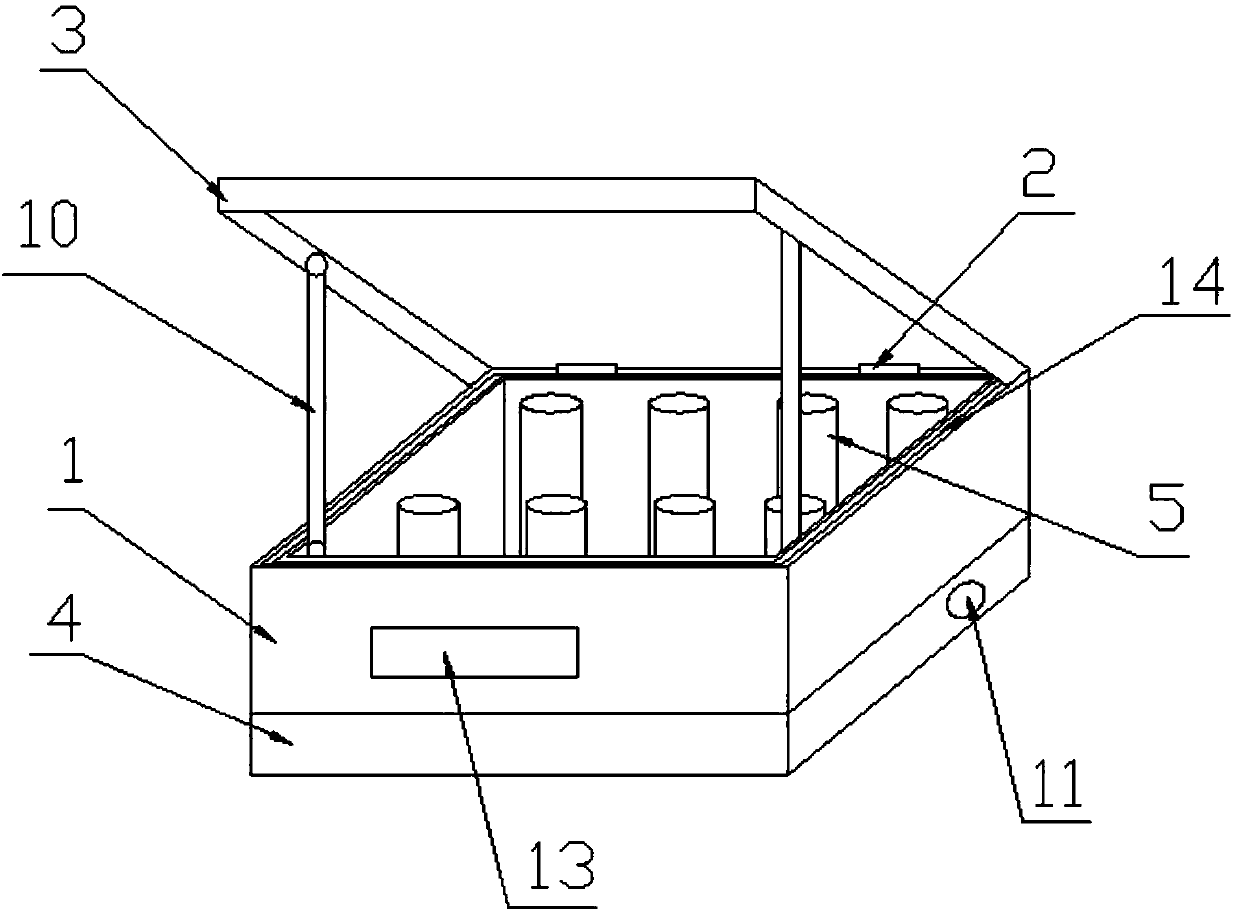

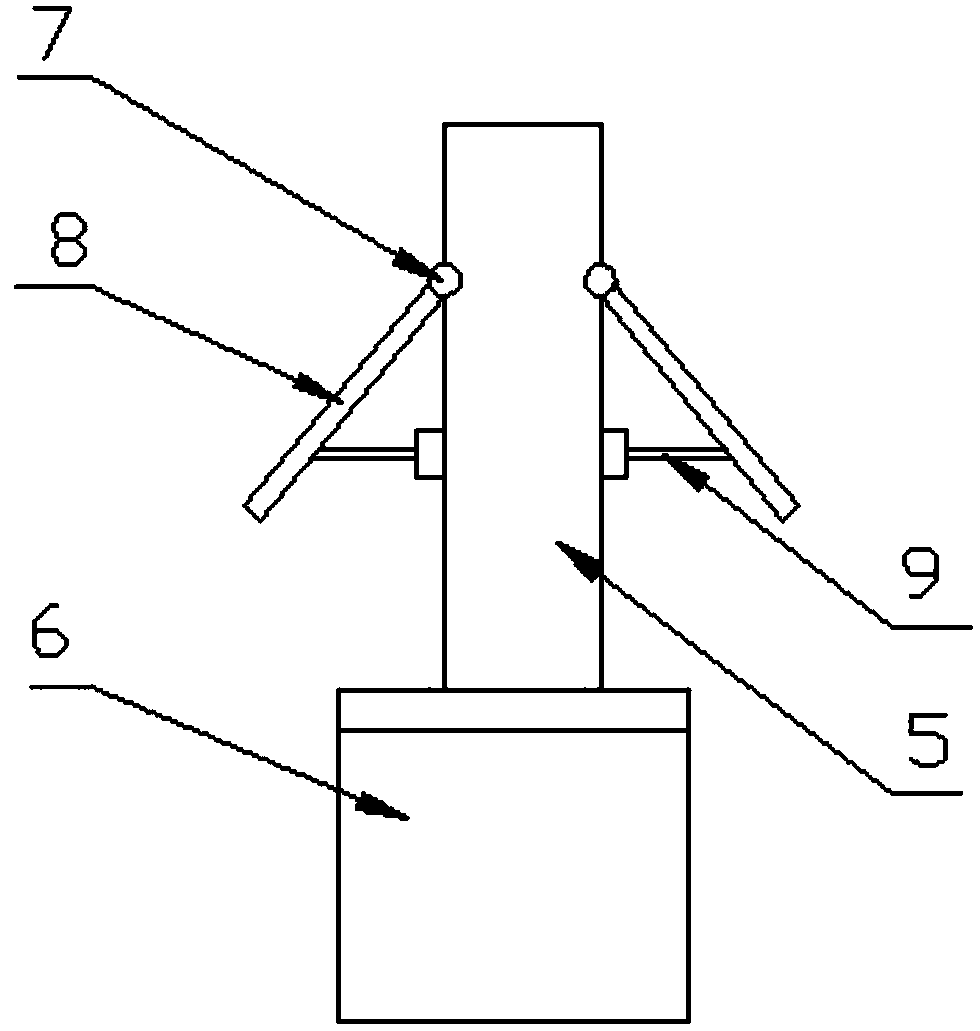

Hollow brick stacking device

InactiveCN107697420AEliminate redox reactionsLess prone to errorsPackaging under vacuum/special atmosphereLidsHollow coreHinge angle

The invention discloses a stacking device for hollow bricks, which comprises a storage box, the storage box is connected to the box cover through a hinge, the top of the storage box is provided with a base, the inside of the storage box is provided with a placement rod, and the bottom of the storage rod is provided with a Gravity sensing, the placement rod is connected to the pallet through the connecting shaft, an electric control support rod is set between the pallet and the placement rod, an electric control lifting rod is provided between the storage box and the box cover, and a drawer is installed inside the base. The trachea and the exhaust pipe are equipped with an evacuation machine, and the operation display screen on the storage box is respectively connected with the gravity sensor, the electric control support rod, the electric control lifting rod and the evacuation electromechanical. The operation display screen, the gravity sensor, the electric The control support rod, the electric control lifting rod and the vacuum machine are all electrically connected with the power supply device. It can prevent dust from falling on the hollow weight when it is placed, and prevents the redox reaction from occurring when it is placed, so that the hollow weight is not easy to cause errors.

Owner:李龙娟

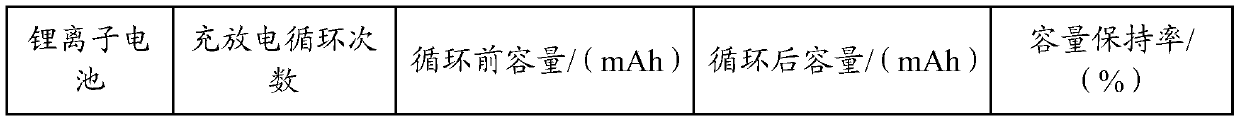

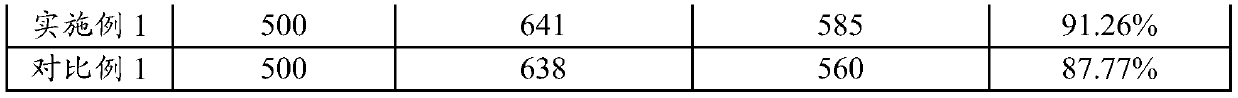

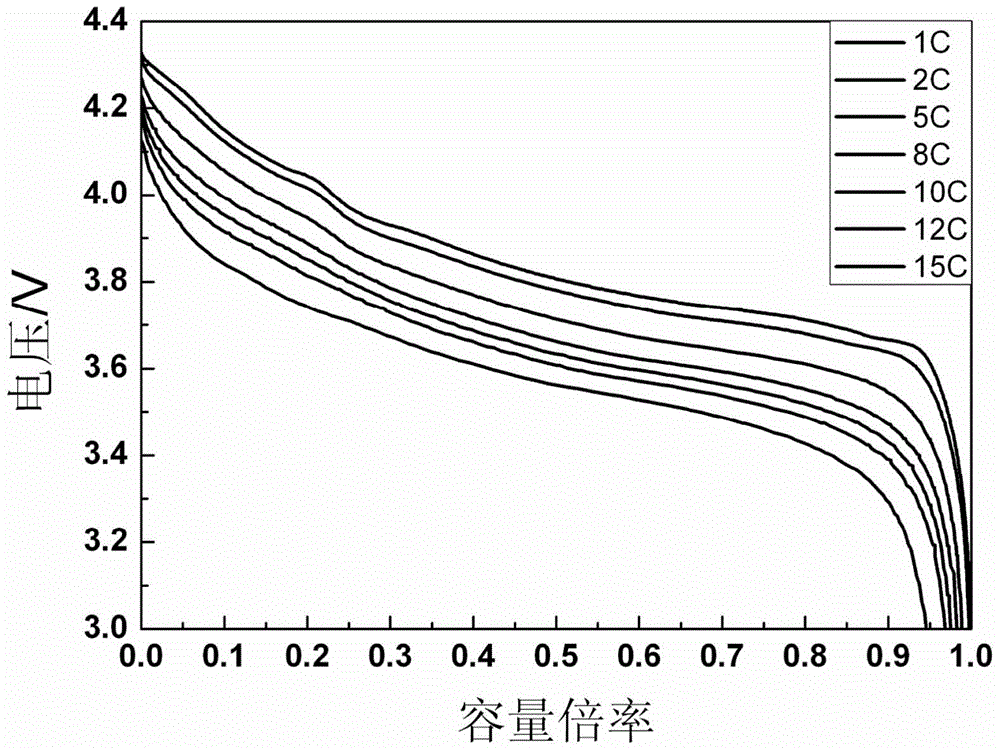

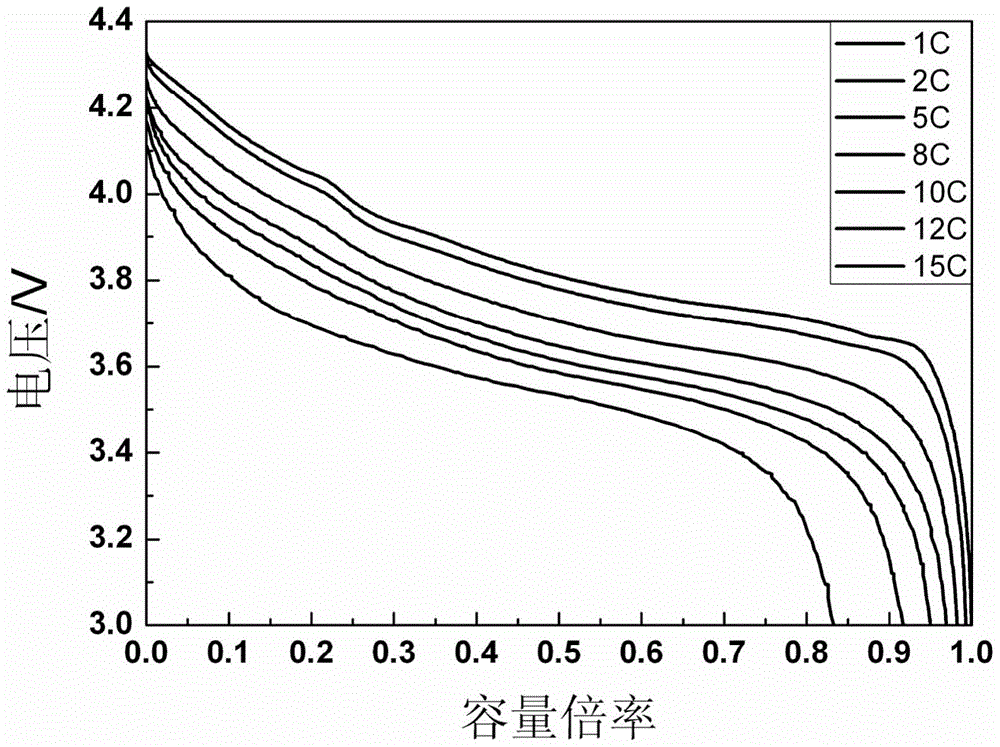

A kind of positive electrode material of lithium ion battery and preparation method thereof

ActiveCN103647073BQuick releaseImprove cycle performanceElectrode thermal treatmentSecondary cellsCarbon coatingCarbon layer

The invention discloses a preparation method of a lithium ion battery anode material. The method is characterized in that the outer surface of the existing lithium ion battery anode material is sequentially coated with an aluminum oxide layer and a carbon layer, wherein the coating condition is liquid-phase coating, in the coating process of the aluminum oxide, the addition sequence of the existing lithium ion battery anode material and aluminum salt is adjusted, and the coating substance organic aluminum salt is added under the continuously stirring condition, so that a hydrolytic product is uniformly adsorbed onto the surface of an active substance. The carbon coating is carried out through a spray drying and rapid sintering way in the inert gas atmosphere, so that the problems that the metal is reduced due to the high-temperature carbon coating and the organic carbon source is difficultly carbonized in low temperature can be avoided. The invention also discloses a lithium ion battery anode material prepared through the method. The energy density and power density of the battery can be remarkably improved, and the cycling performance, the capacity retention rate and the safety performance of the battery can be improved.

Owner:EVE ENERGY CO LTD

Hot blast stove running in high pressure

InactiveCN109425107AAvoid enteringEasy accessPump componentsMaintainance of heating chambersEngineeringHigh pressure

Owner:张跃

Suppression structure for thermal failure diffusion of battery system, determination method of inhibition structure and battery system

ActiveCN112018459AImprove securityReduce heat releaseFinal product manufactureFire rescuePower batteryElectrical battery

The invention relates to a suppression structure for thermal failure diffusion of a battery system, a determination method thereof and the battery system. The suppression structure for thermal failurediffusion of the battery system comprises a shell, a chemical inhibitor and a lead. The chemical inhibitor is used for inhibiting the redox reaction during thermal failure of the battery, so that theheat release of the thermal failure of the battery monomer is weakened fundamentally, and the thermal failure of other battery monomers caused by the thermal failure of the battery monomer is avoided. And the lead is exposed out of the shell and can be in contact with the single battery subjected to thermal failure at first. And after the lead is triggered, the chemical inhibitor connected with the lead is triggered and is used for inhibiting the oxidation-reduction reaction during thermal failure of the battery. The chemical inhibitor and the lead in the inhibition structure for thermal failure diffusion of the battery system act together, so that the safety of the battery system is improved. The suppression structure for thermal failure diffusion of the battery system has important value for safety design of a high-specific-energy power battery.

Owner:TSINGHUA UNIV

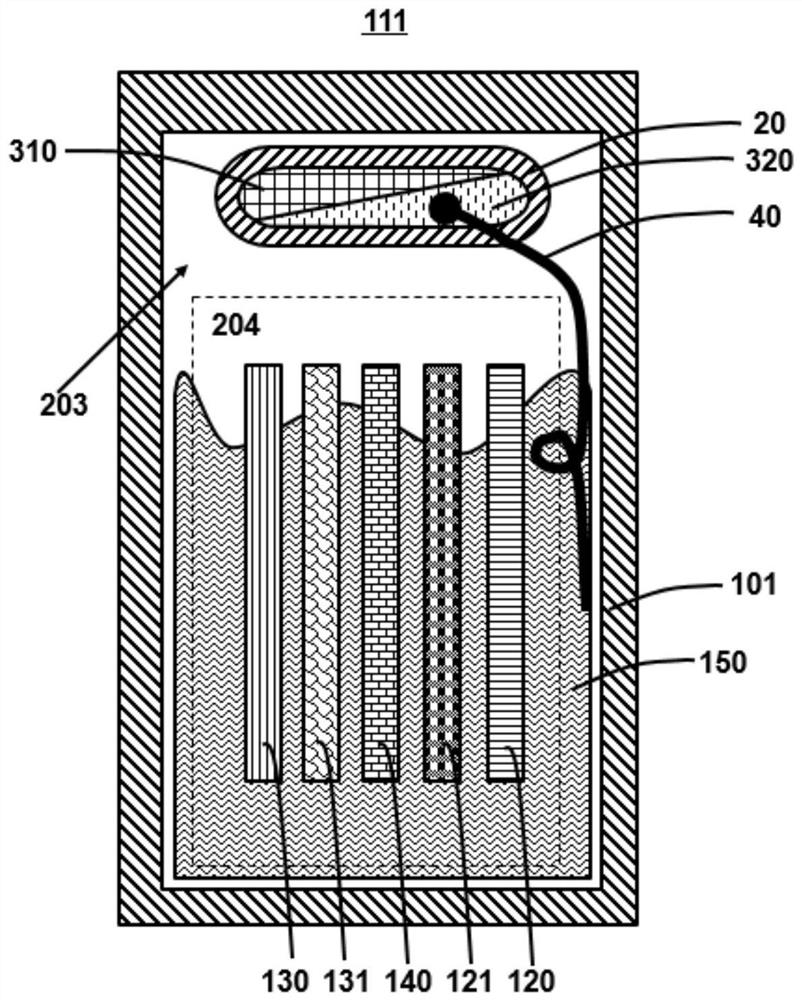

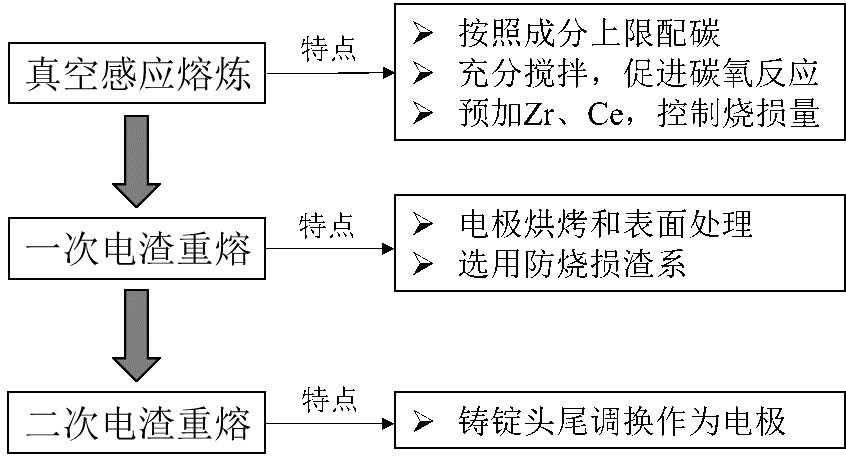

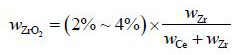

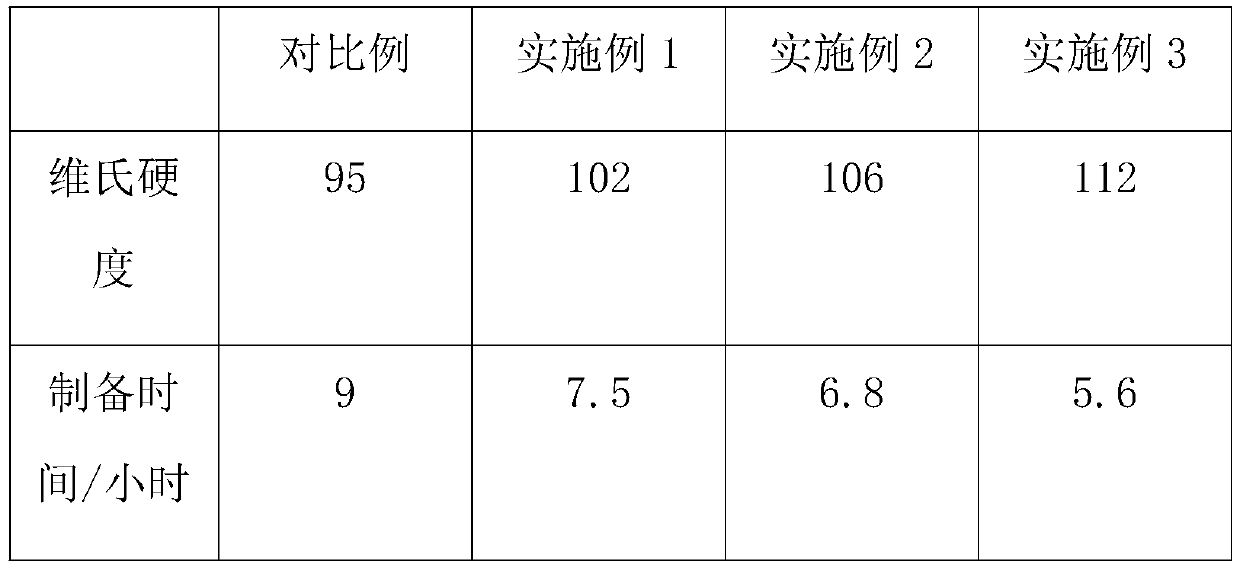

A kind of deformed superalloy containing zr-ce and preparation method thereof

The invention relates to a deformed superalloy containing Zr-Ce and a preparation method thereof. The method: prepare the raw materials; carry out vacuum induction smelting on the raw materials according to chemical material, refining and pouring in sequence: in the refining period, pre-add a small amount of zirconium and cerium to continue refining for 10 ~ 15 minutes, and detect the burning loss of zirconium and cerium; then add the remaining zirconium and cerium and the burned zirconium and cerium to continue refining for 10~15 minutes; during the pouring period, pour the refined alloy melt to obtain a vacuum induction ingot Carry out electroslag remelting to the vacuum induction ingot to obtain a deformed superalloy containing Zr-Ce; the slag material used in the electroslag remelting contains CaF 2 , CaO, Al 2 O 3 、TiO 2 , ZrO 2 and CeO 2 . The invention can be used to accurately control the contents of Zr and Ce elements in the alloy, and improve the purity of the alloy and the uniformity of element distribution.

Owner:UNIV OF SCI & TECH BEIJING

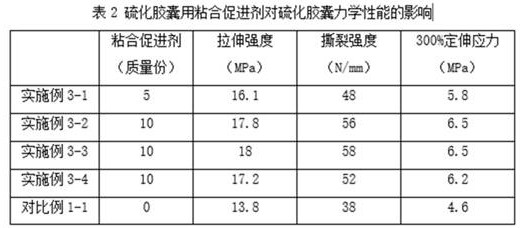

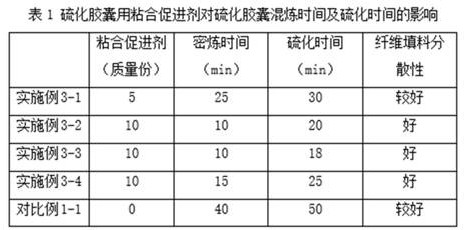

Adhesion promoter for vulcanization capsule and preparation method thereof

The present invention relates to the technical field of auxiliary agents for vulcanization capsules, in particular to an adhesion promoter for vulcanization capsules and a preparation method thereof, an adhesion promoter for vulcanization capsules, and the adhesion promoter for vulcanization capsules is a core-shell structure, the core body is modified zinc oxide / attapulgite composite, and the shell is liquid butadiene rubber grafted with maleic anhydride; zinc oxide accounts for (35-40) wt% of the total amount of the core body; maleic anhydride It accounts for (17-25) wt% of the total amount of the shell; and the shell accounts for (60-65) wt% of the total amount of the adhesion promoter for the vulcanization bladder. The adhesive for vulcanization bladder provided by the present invention has good dispersibility and reinforcing effect in butyl rubber, reduces production cost, can improve the adhesion between butyl rubber, fiber filler and various processing aids, greatly The mixing time and vulcanization time of rubber materials are greatly reduced, and the production efficiency and overall mechanical properties of vulcanization bladders are improved.

Owner:山东永誉橡胶有限公司

Preparation method of nonferrous metal alloy material

The invention discloses a nonferrous metal alloy material. The nonferrous metal alloy material comprises main materials and auxiliary materials, wherein the main materials comprises the following components of, in parts by weight, 8 parts-15 parts of elemental tin, 20 parts-30 parts of elemental nickel, 5 parts-12 parts of copper oxide, 2 parts-10 parts of metallic magnesium ore soil, 10 parts-20parts of cobaltite, 20 parts-40 parts of a copper-iron mixture, 5 parts-20 parts of sodium thiosulfate, 12 parts-25 parts of aluminum sulfate, 18 parts-30 parts of sodium nitrate, 4 parts-10 parts ofaluminum oxide, and 5 parts-20 parts of potassium chloride; and the auxiliary materials comprises the following components of, in parts by weight, 5 parts-20 parts of phosphorus, 10 parts-50 parts ofstearic acid, 20 parts-50 parts of carbide, 20 parts-40 parts of silicide and 10 parts-30 parts of boride. The invention relates to the technical field of alloys. According to the preparation method of the nonferrous metal alloy material, through combined arrangement of phosphorus, carbide, silicide, boride and graphite powder in the auxiliary materials, in the smelting preparation process, the auxiliary materials can react with gangue oxide contained in the main materials at the gradually-increased high temperature, and a low-melting-point slag layer is formed, so that the alloy metal is fused together stably, the auxiliary materials float on the surface of the molten metal after reacting with the impurities, and are not mixed with the molten metal.

Owner:中山市皓祥模具五金有限公司

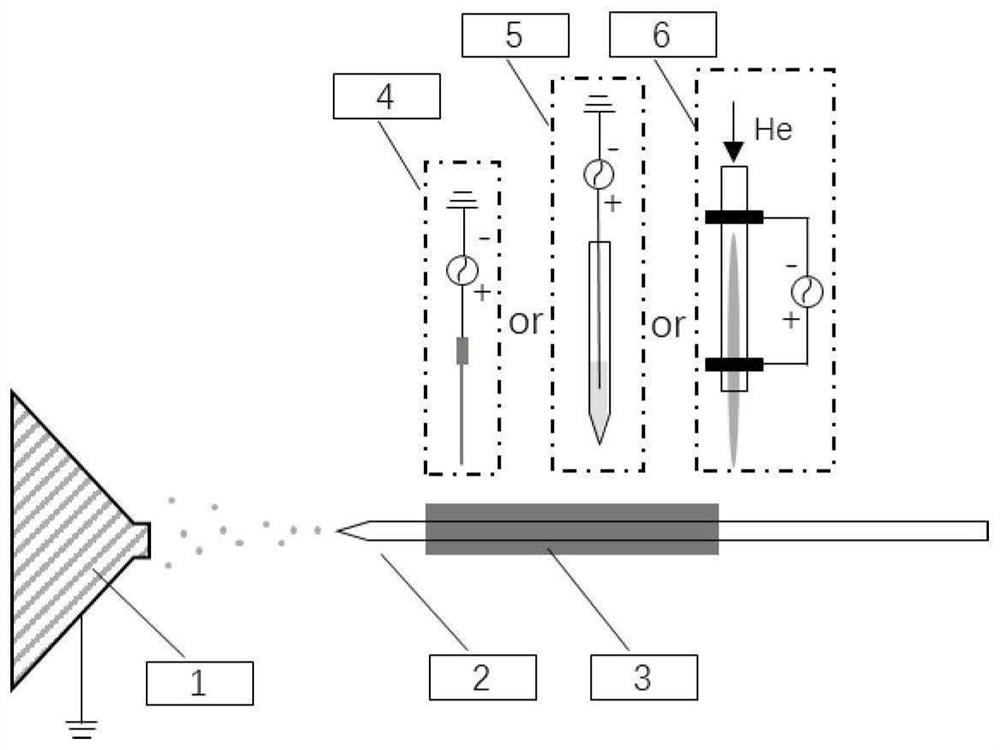

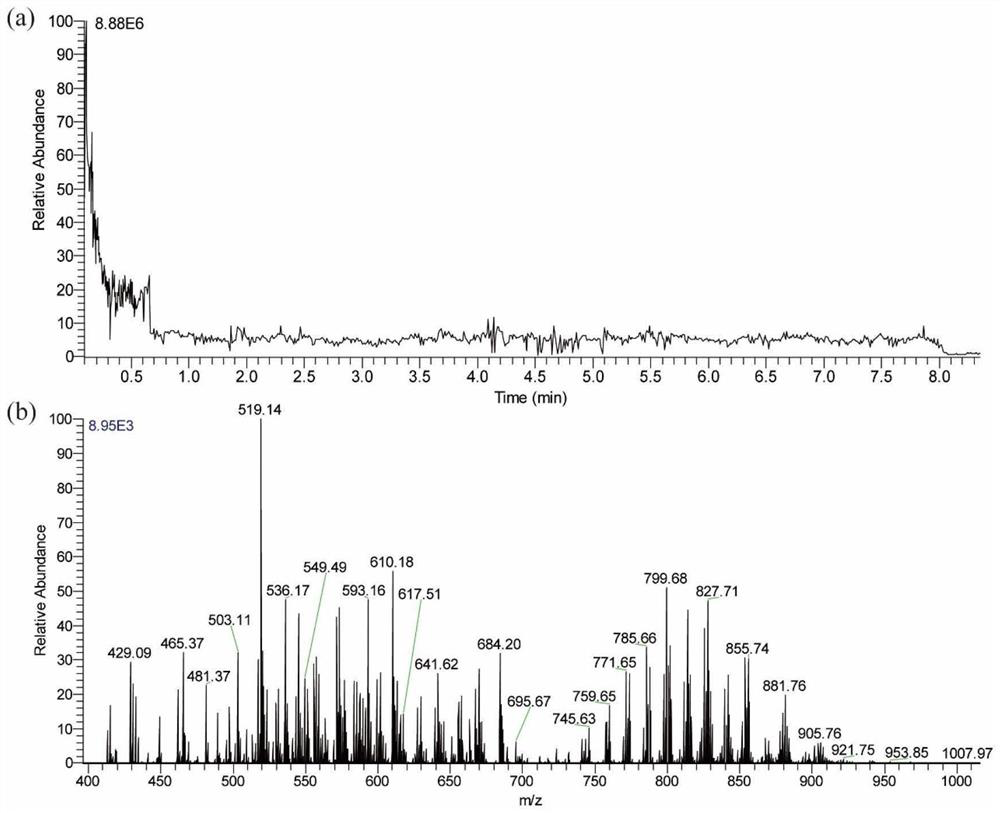

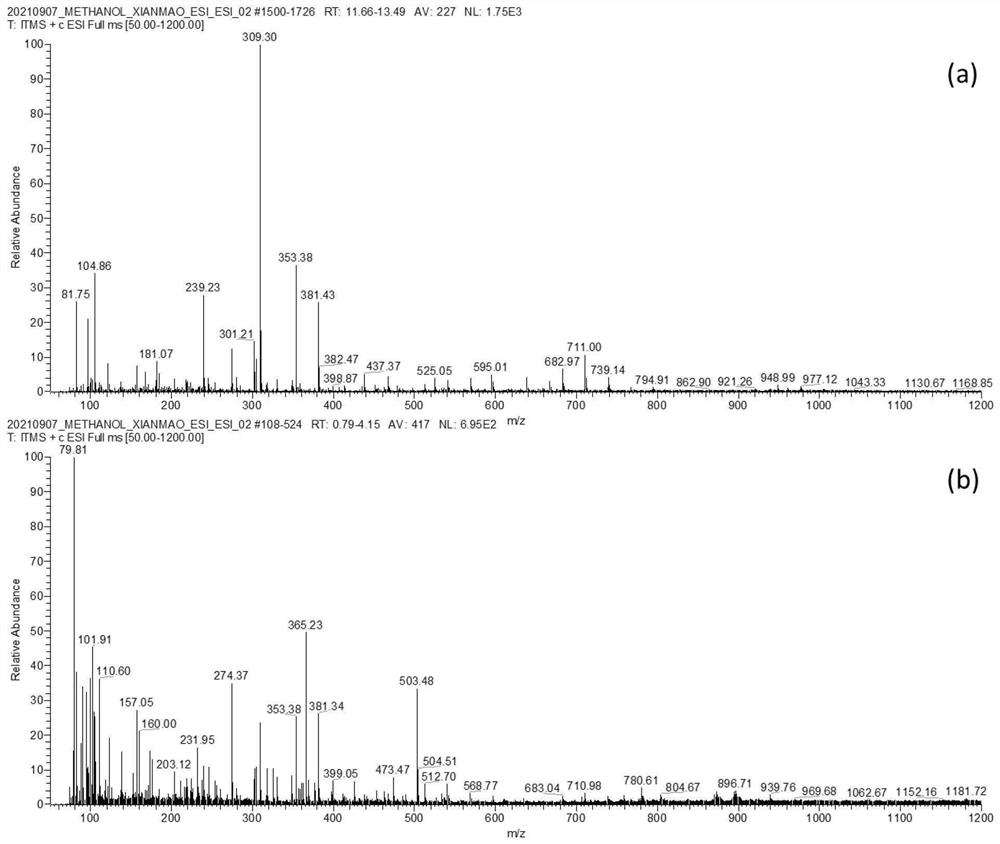

Electrospray excitation device and ionization method

PendingCN114496717AReduce flow rateAvoid redox reactionsIon sources/gunsElectro sprayCapillary Tubing

The invention discloses an electrospray excitation device and an ionization method, relates to the technical field of mass spectrometry, and utilizes a charge generation device to induce a capillary tube to generate electrospray. Specifically, a conductive coating material is used for collecting charges generated by a charge generation module, and the charges act on a spray capillary tube, so that a solvent is subjected to electrospray ionization to generate ions which enter a mass spectrometer for detection. Electro-spray can be generated under the condition that high pressure is not in contact with a spray solvent, and electrochemical side reaction and redox reaction of an analyte caused by contact of an electrode and the solvent are effectively avoided. Meanwhile, the flow velocity of the electrospray can be as low as picoliter level, the analysis time of an ultramicro sample can be long enough, and abundant mass spectrum signals can be collected. The method has the advantages of simple operation steps, high sensitivity and strong stability.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Waterproof pigment, preparing method and use thereof

InactiveUS20130295386A1Preventing oxidation-reduction reactionAvoid redox reactionsPigmenting treatmentLiquid surface applicatorsPigmentMetal

A waterproof pigment, the preparing method and the use thereof are provided. The pigment has a primary flake with a layered structure of at least three layers including a top layer, an assembled intermediate layer and a bottom layer, wherein the assembled intermediate layer has at least one layer of active metal. The pigment has a coating on the side of the primary flake only.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

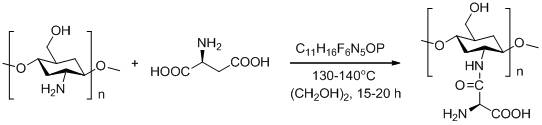

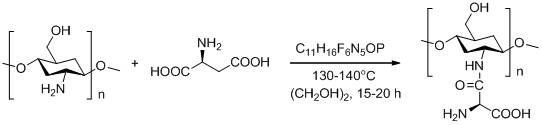

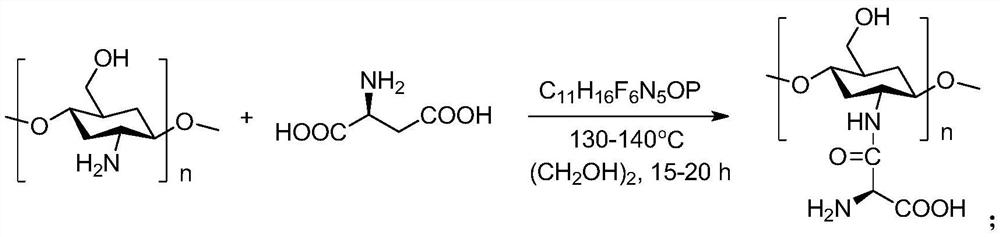

A kind of highly stable modified water-based phenolic resin anticorrosion coating and its preparation method

ActiveCN110628293BImprove stabilityGood chemical stabilityAnti-corrosive paintsHyaluronic acid coatingsResin coatingAspartic acid

Owner:QINGYANG ZHOUYANG MACHINERY MFG

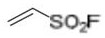

A kind of lithium ion battery electrolyte additive and lithium ion battery electrolyte

ActiveCN110931872BLower redox potentialAvoid redox reactionsFinal product manufactureSecondary cells servicing/maintenancePropanoic acidMethyl carbonate

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

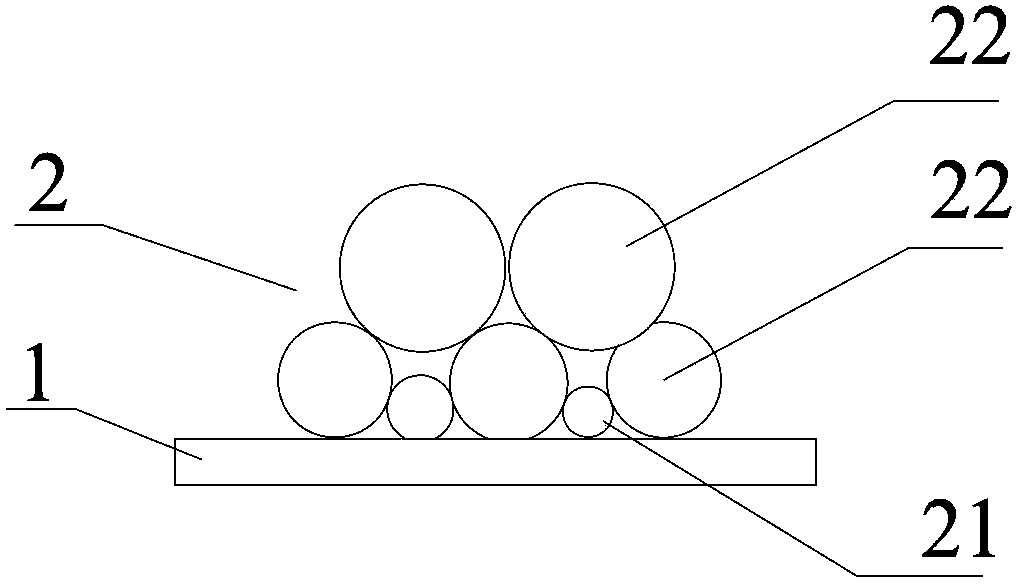

Aqueous lithium-ion battery composite electrode and preparation method thereof, and aqueous lithium-ion battery

ActiveCN103904290BIncrease working voltageWith waterproof functionElectrode manufacturing processesSecondary cellsSolid state electrolyteComposite electrode

The invention discloses an aqueous lithium ion battery composite electrode, a preparation method of the composite electrode and an aqueous lithium ion battery. The aqueous lithium ion battery composite electrode comprises a positive electrode piece or a negative electrode piece and a solid electrolyte membrane coating layer, wherein an active material layer is combined with the surface of the positive electrode piece or the surface of the negative electrode piece; the solid electrolyte membrane coating layer is used for packaging the active material layer of the positive electrode piece or the negative electrode piece in a vacuum mode. Through the aqueous lithium ion battery composite electrode, the direct contact between the positive electrode active material layer or the negative electrode active material layer and water of an aqueous electrolyte can be prevented, so that hydrogen evolution reaction and oxygen evolution reaction of the aqueous electrolyte can be prevented, and thus side reaction between active substances and the water can be prevented. The aqueous lithium ion battery comprises a positive aqueous lithium ion battery composite electrode and a negative aqueous lithium ion battery composite electrode, so that high voltage and energy density are provided for the aqueous lithium ion battery.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com