Hollow brick stacking device

A technology of stacking hollow bricks, which is applied in the field of brick stacking devices, can solve the problems of non-standard quality of weights, etc., and achieve the effects of not being prone to errors, eliminating oxidation-reduction reactions, and having a wide range of usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

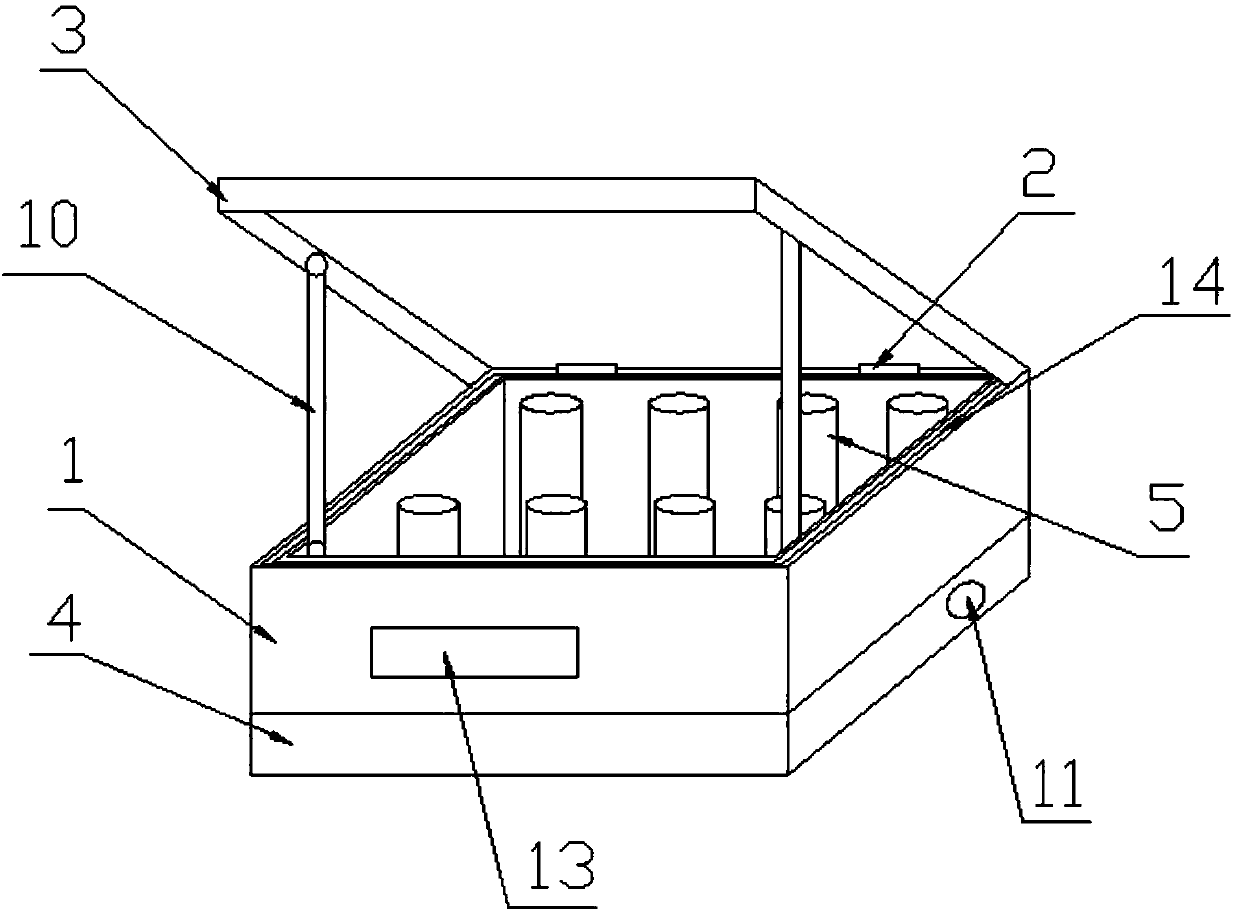

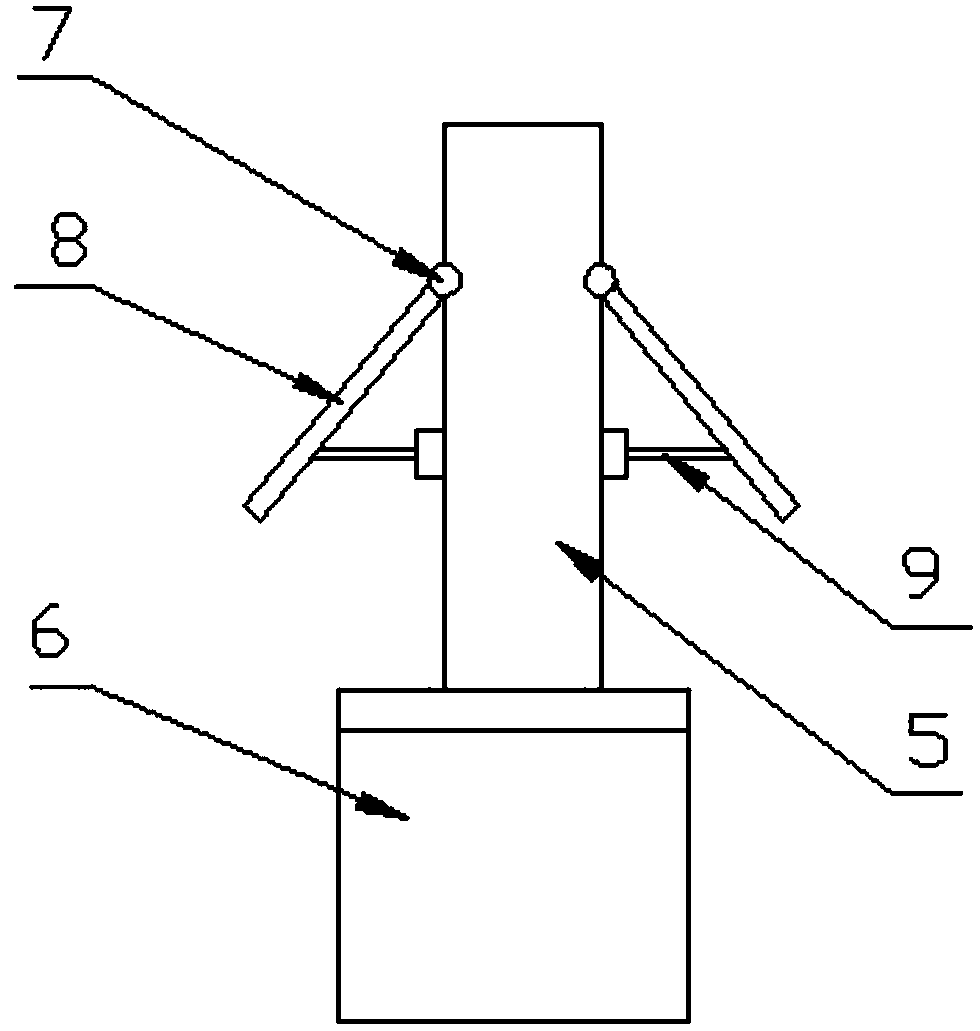

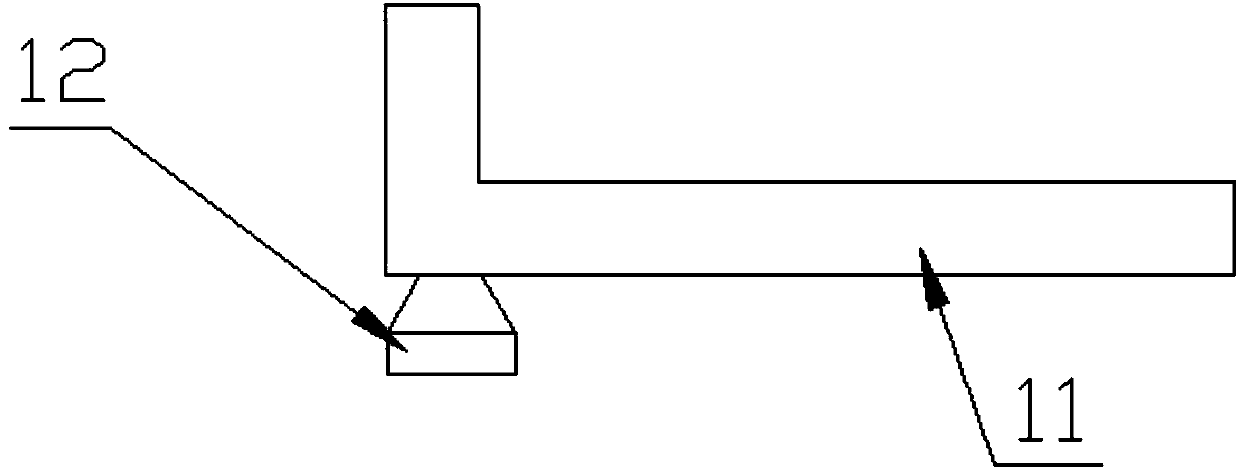

[0019] like Figure 1-3 As shown, the present invention provides a hollow brick stacking device, comprising a storage box 1, the storage box 1 is connected to the box cover 3 through a hinge 2, the top of the storage box 1 is provided with a base 4, and the inside of the storage box 1 is provided with Place the sleeve rod 5, set the gravity sensor 6 at the bottom of the placement sleeve rod 5, place the sleeve rod 5 to connect the clamp 8 through the connecting shaft 7, and set an electric control support rod 9 between the clamp 8 and the placement sleeve rod 5, and store the box An electric control elevating rod 10 is arranged between the body 1 and the case cover 3 , and the inside of the base 4 is provided with an air extraction pipe 11 on which an evacuator 12 is arranged.

[0020] The operation display screen 13 on the storage box 1 is electrically connected with the gravity sensor 6, the electric control strut 9, the electric control lifting rod 10 and the vacuum machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com