Circuit board visual detection mechanism and detection method thereof

A visual inspection and circuit board technology, applied in sorting and other directions, can solve problems such as low efficiency, subsequent use errors, and detection effect errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

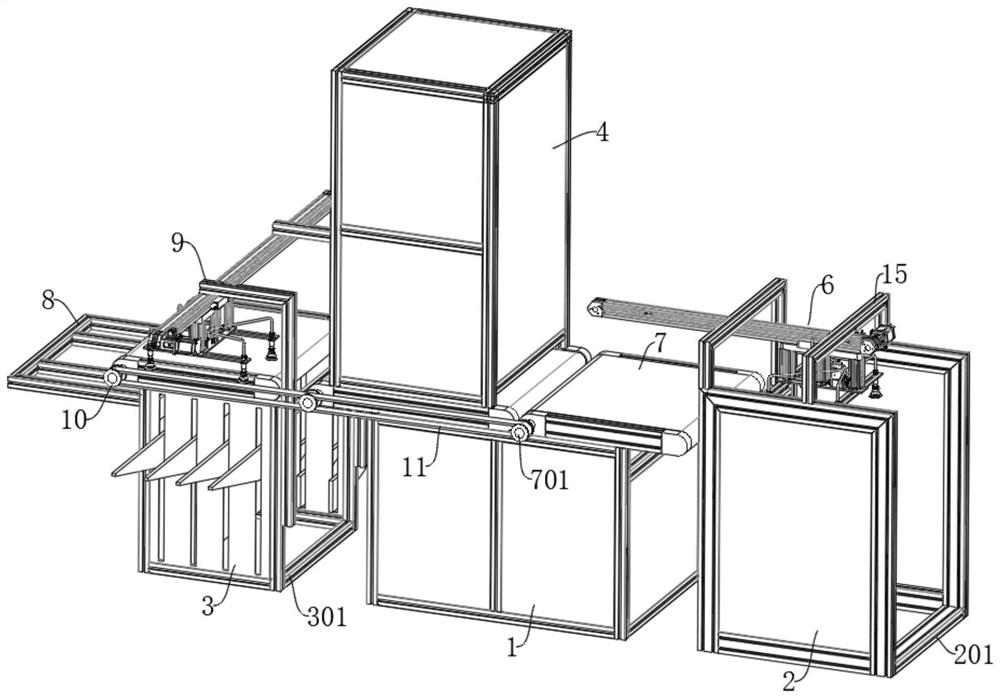

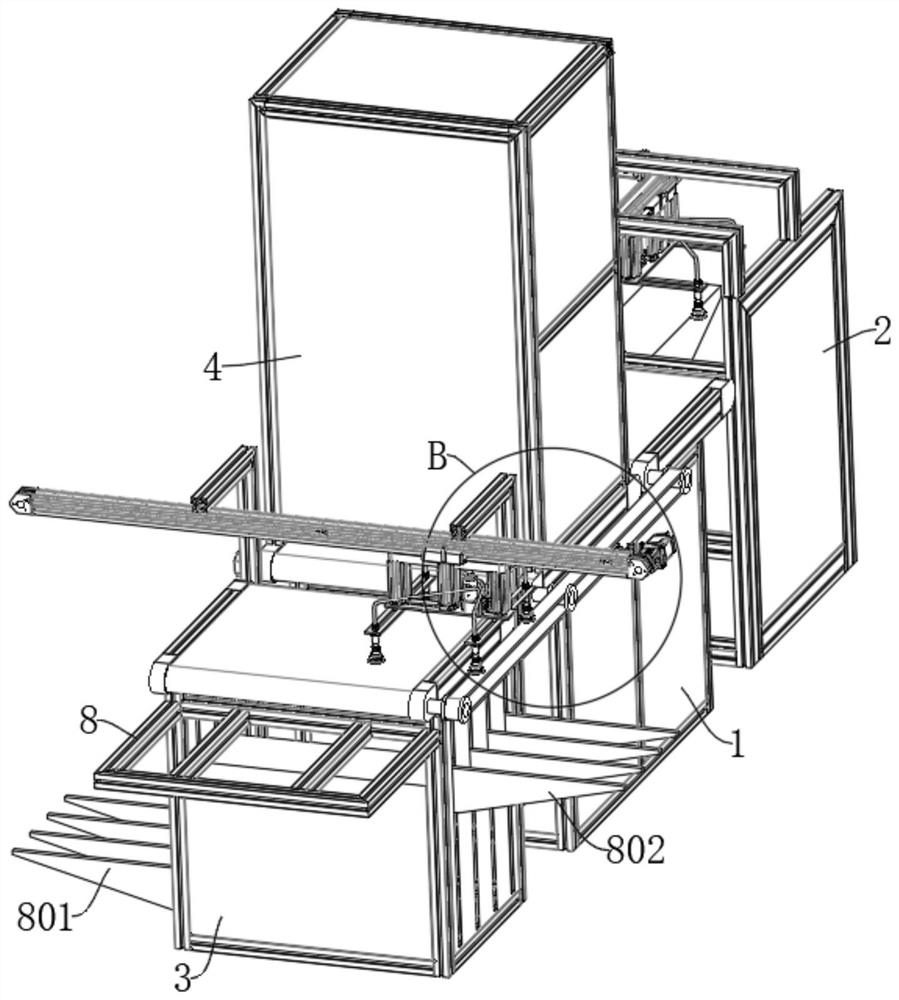

[0043] see Figure 1-8 , the present invention provides the following technical solutions:

[0044] Board visual inspection mechanism, including:

[0045] The support base 1, the left and right sides of the support base 1 are respectively provided with two second support plates 3 and a first support plate 2;

[0046] A feeding mechanism, the feeding mechanism is located between the two first support plates 2, and the feeding mechanism is used to carry the circuit board;

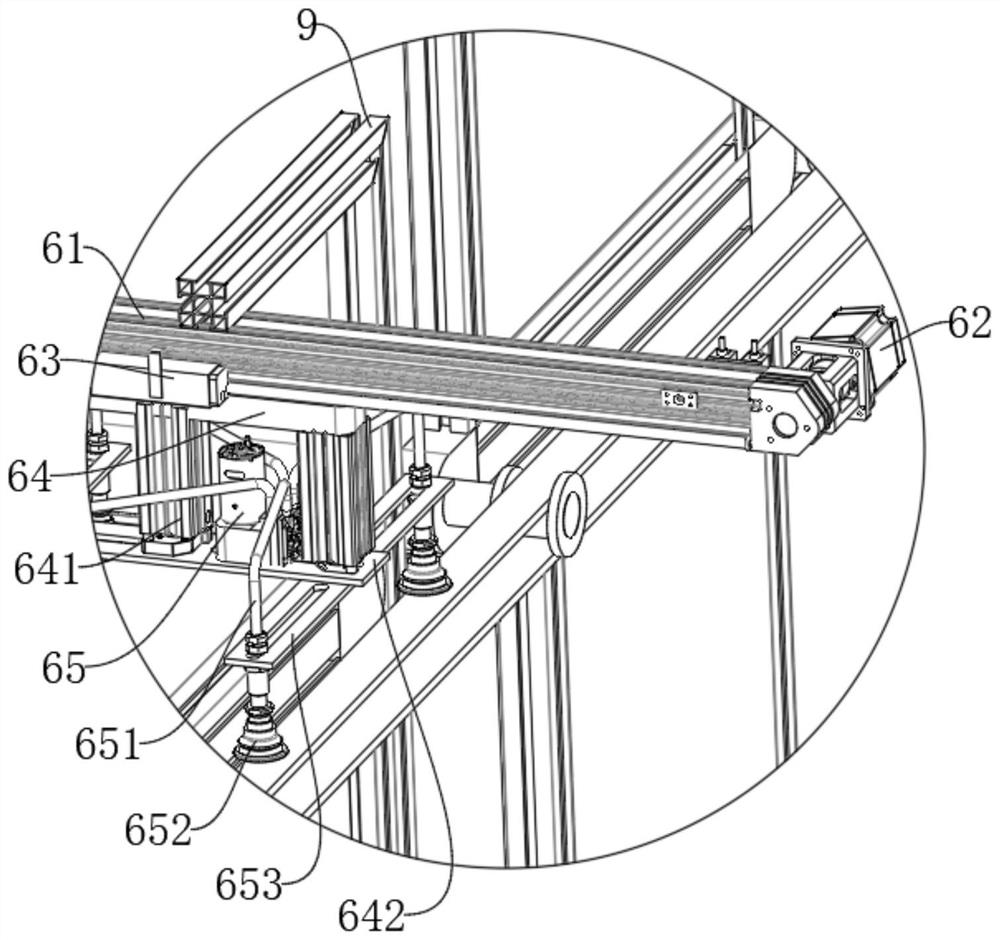

[0047] Two sets of grasping mechanisms 6, two sets of grasping mechanisms 6 are respectively located on the upper side of the second support plate 3 and the first support plate 2, and the two sets of grasping mechanisms 6 are respectively used to grasp the circuit board and make it move horizontally or vertically move in a straight line;

[0048] Two gantry frames 15, the bottoms of the two gantry frames 15 are respectively fixed on the upper ends of the two first supporting plates 2, and the two gantry fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com