Packaging method and packaging assembly line for ceramic sheets

A packaging line, ceramic sheet technology, applied in the field of ceramic tile packaging, can solve the problems of reducing product quality, brittleness, product surface scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

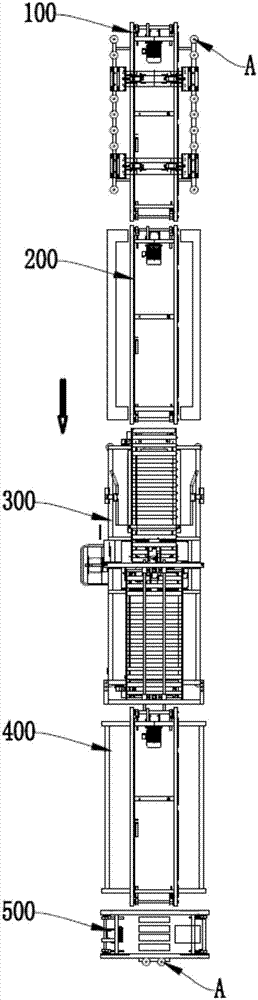

[0047] Such as figure 1 Shown, a kind of ceramic sheet packing method, comprises the steps:

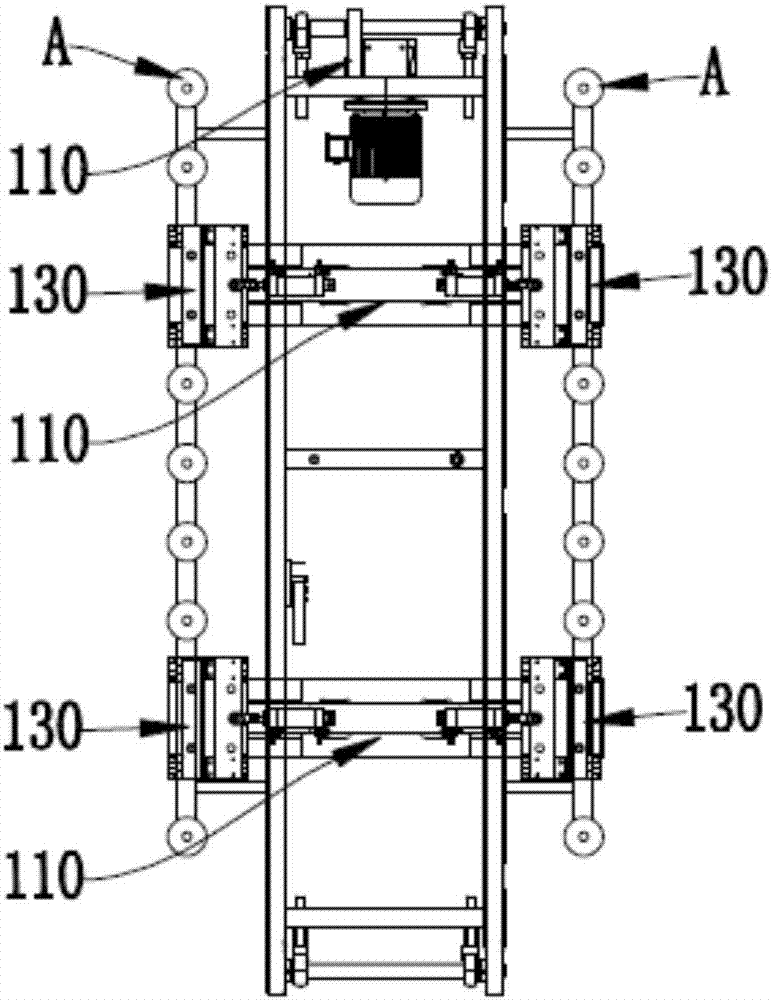

[0048] Step 1) Stacking the ceramic thin plates: placing the ceramic thin plates in the lifting stacking device 100, stacking no less than three types of ceramic thin plates, so that multiple ceramic thin plates are stacked;

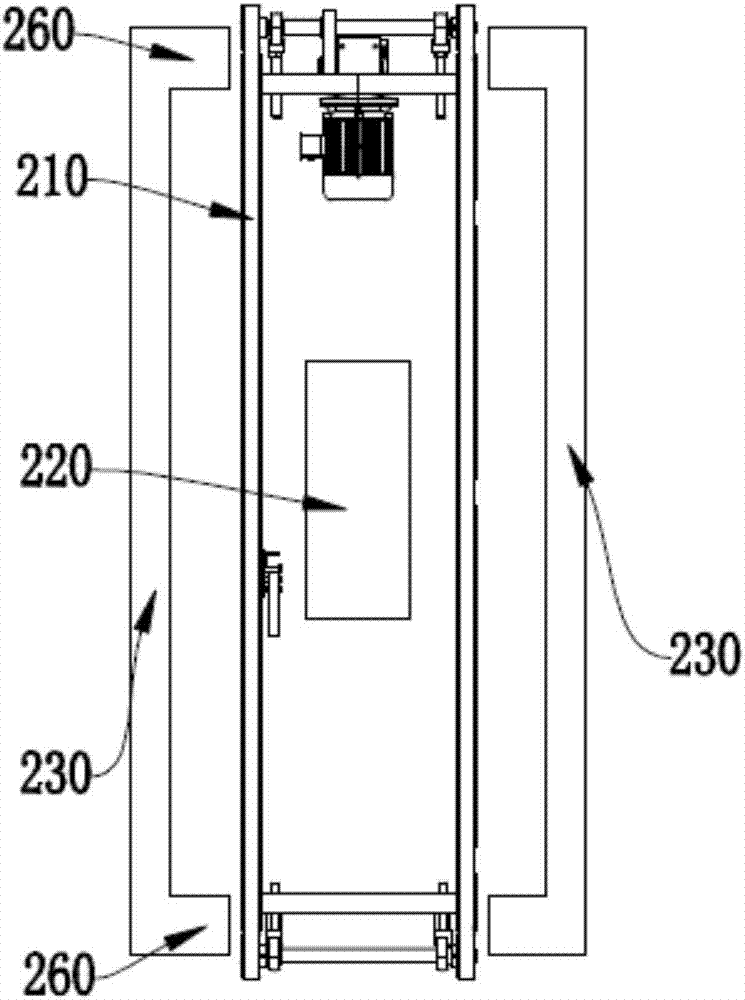

[0049] Step 2) Wrapping the ceramic thin plates: transport the laminated ceramic thin plates to the packaging device 200, the packaging device 200 will lift the laminated ceramic thin plates, place packaging cardboard on the bottom of both sides of the ceramic thin plates, and fold the packaging cardboard to stack Wrapped on both sides of the ceramic sheet;

[0050] Step 3) Bundle the packaging cardboard: the packaged ceramic sheet package is transported to the packaging device 300,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com