Anode and preparation method thereof, lithium battery

A lithium battery and negative electrode technology, applied in the field of negative electrode and its preparation, can solve the problems of strong corrosion, poor stability of LiF layer, etc., and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

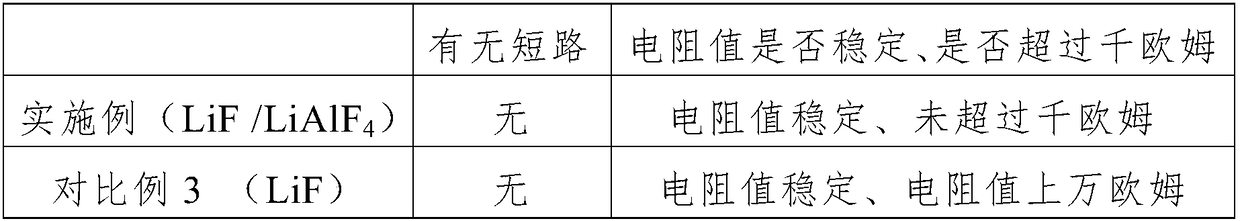

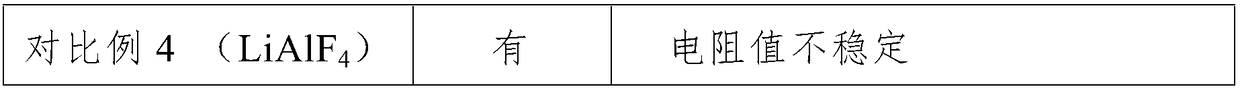

[0060] According to one embodiment of the negative electrode of the present invention, it includes: a lithium negative electrode sheet; LiF layers deposited on the first and second surfaces of the lithium negative electrode sheet respectively; LiAlF deposited on the LiF layer respectively 4 layer.

[0061] This embodiment is the above-mentioned double-sided deposition. During double-sided deposition, the winding or stacking assembly method of the all-solid-state battery can be realized. When this assembly method is adopted, due to the LiAlF 4 layer, can reduce the amount of solid electrolyte or omit the addition of solid electrolyte (when LiAlF 4 When the thickness of the layer is large), the energy density of the all-solid-state battery can thus be improved.

[0062] According to one embodiment of the negative electrode of the present invention, the thickness of the lithium negative electrode sheet is 0.8um to 1000um; the thickness of the LiF layer is 10nm to 200nm, preferab...

Embodiment 1

[0091] (1) Provide lithium negative electrode sheet: hot pressing of metal lithium foil. The specific operation is as follows:

[0092] Using commercial lithium metal foil with a thickness of 1000um as raw material, adjust the width of the hot press roller to 100um in the argon glove box, put the metal lithium foil from the entrance, turn on the hot press, and set the hot press to two times. The temperature of the pressing roller is 25°C, and the metal lithium foil is stretched and thinned by mechanical driving, and a 100um metal lithium foil is obtained at the exit, which is a lithium negative electrode sheet.

[0093] (2) S1: Deposit LiF layer on the first side of the lithium negative electrode by magnetron sputtering method; S2: Deposit LiAlF on the LiF layer on the first side by magnetron sputtering method 4 layer. The specific operation is as follows:

[0094] Place the metal lithium foil with a thickness of 100um on the base of VTC-600-3HD three-target magnetron sputt...

Embodiment 2

[0096] (1) Provide lithium negative electrode sheet: hot pressing of metal lithium foil. The specific operation is as follows:

[0097] Using commercial lithium metal foil with a thickness of 1000um as the raw material, adjust the roller pressure gap width of the hot press to 50um in an argon glove box, put the lithium metal foil from the entrance, turn on the hot press, and set the temperature of the hot press. The temperature of the two pressure rollers is 120°C, and the metal lithium foil is stretched and thinned by mechanical driving, and a 50um metal lithium foil is obtained at the exit.

[0098] (2) S1: Deposit LiF layer on the first side of the lithium negative electrode by magnetron sputtering method; S2: Deposit LiAlF on the LiF layer on the first side by magnetron sputtering method 4 layer. The specific operation is as follows:

[0099] Place the first side of the metal lithium foil with a thickness of 50um upwards on the base of the VTC-600-3HD three-target magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com