Hot blast stove running in high pressure

A hot blast stove and high-pressure technology, which is applied in the direction of furnace, furnace cooling, furnace charge, etc., can solve the problems of small reserved space in the working chamber of the furnace body, reduce the strength of the workpiece, and slow cooling speed, so as to prevent external air from entering the furnace body , Prevent oxidation-reduction reaction, prevent oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

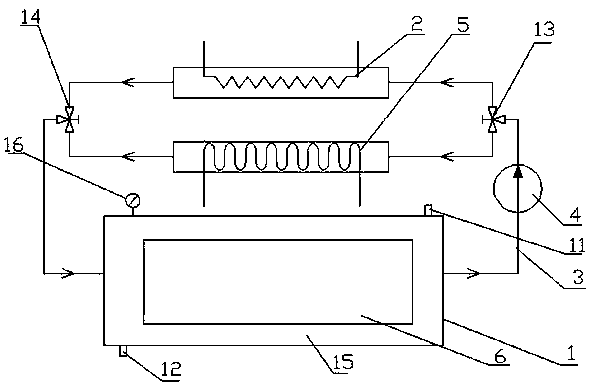

[0031] like figure 1 Shown: a high-pressure operating hot blast stove, including a furnace body 1, the outer shell of the furnace body 1 is wrapped by a water-cooled jacket. The furnace body is provided with an air inlet 11 and an air outlet 12, the air inlet 11 is provided with an air inlet valve, and the air outlet 12 is provided with an exhaust valve.

[0032] The outside of the furnace body 1 is provided with a heating body 2 and a cooler 5. The heating body 2 and the cooler 5 are connected to the inlet and outlet of the furnace body 1 through a circulation pipeline 3. The heating body 2 and the cooler 5 are connected to two ends of a circulation pipeline. On the branch road, that is, the heating branch and the cooling branch, the front electric three-way valve 13 and the rear electric three-way valve 14 are arranged at the junction of the two ends of the heating branch and the cooling branch, to switch between the hot air channel and the cold air channel, And the valve o...

Embodiment 2

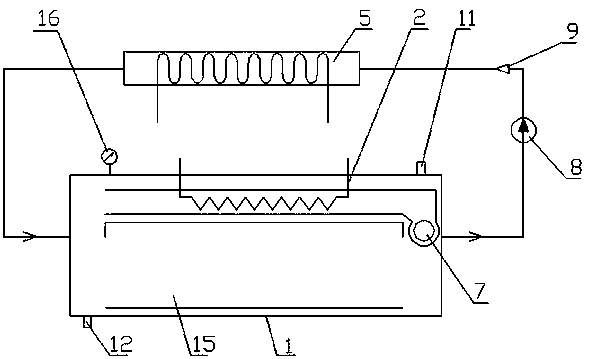

[0040] like figure 2 Shown: the difference with embodiment 1 is that the hot air circulation is an internal circulation mode. The inner tank of the furnace body 1 is divided into a working cavity 15 and a heating zone, and the working cavity 15 and the heating zone are two different chambers, and the two are communicated with each other. A heating body 2 is arranged in the heating zone.

[0041] The workpiece is placed in the working chamber 15 . The furnace body 1 is provided with a main fan 7, and the impeller of the main fan 7 is a centrifugal impeller. The motor, motor shaft and impeller of the main fan 7 are all arranged in the body of heater 1, and the motor and the motor shaft are wrapped by a water-cooled jacket. The outside of the body of furnace 1 is provided with a quick cooling fan 8 and a cooler 5, and the quick cooling fan 8, the cooler 5 and the working chamber 15 are connected through pipelines, and the pipeline between the quick cooling fan 8 and the coole...

Embodiment 3

[0046] The difference from Embodiment 2 is that a heating body is provided in the working chamber of the furnace body, and the heating body and the working chamber are connected through a partition, and the heating body communicates with the working chamber.

[0047] Other structures are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com