Preparation method of nonferrous metal alloy material

A technology of alloy materials and non-ferrous metals, applied in the field of alloys, can solve the problems of low hardness and low strength of alloy materials, achieve the effects of improving stability, improving purity, and avoiding redox reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

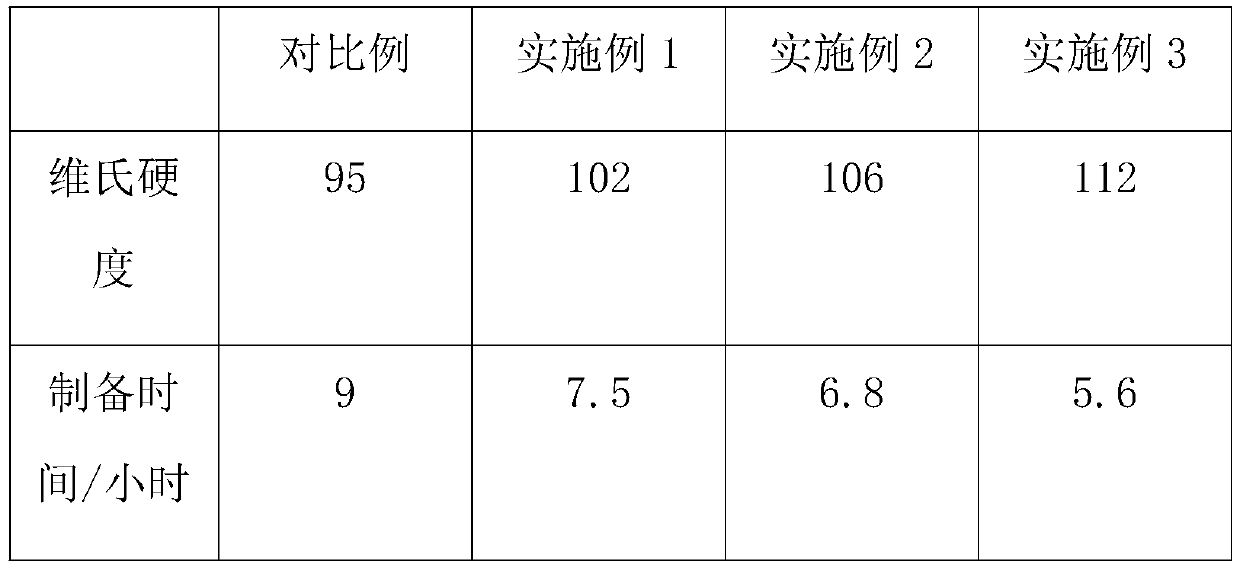

Embodiment 1

[0033] Step 1: Prepare the working equipment: clean the placed working equipment, power on the device after cleaning, and wait for standby;

[0034] Step 2: Preparation of non-ferrous metal alloy materials: Use a rolling device to carry out deep rolling on graphite powder and other materials, then pass the rolled material powder through the screening machine for screening, and use the collection box to collect the rolled and screened materials stand up;

[0035] Step 3: Mix the proportioned materials (ie: 8 parts of elemental tin, 20 parts of elemental nickel, 5 parts of copper oxide, 2 parts of metal magnesium ore soil, 10 parts of cobaltite, 20 parts of copper-iron mixture, sodium thiosulfate 5 parts, 12 parts of aluminum sulfate, 18 parts of sodium nitrate, 4 parts of aluminum oxide, 5 parts of potassium chloride, 5 parts of phosphorus, 10 parts of stearic acid, 20 parts of carbide, 20 parts of silicide, 10 parts of boride, graphite 10 parts of powder) into the crucible in...

Embodiment 2

[0040]Step 1: Prepare the working equipment: clean the placed working equipment, power on the device after cleaning, and wait for standby;

[0041] Step 2: Preparation of non-ferrous metal alloy materials: Use a rolling device to carry out deep rolling on graphite powder and other materials, then pass the rolled material powder through the screening machine for screening, and use the collection box to collect the rolled and screened materials stand up;

[0042] Step 3: Mix the proportioned materials (ie: 10 parts of elemental tin, 25 parts of elemental nickel, 8 parts of copper oxide, 6 parts of metal magnesium ore soil, 15 parts of cobaltite, 30 parts of copper-iron mixture, sodium thiosulfate 12 parts, 18 parts of aluminum sulfate, 24 parts of sodium nitrate, 7 parts of aluminum oxide, 12 parts of potassium chloride, 12 parts of phosphorus, 30 parts of stearic acid, 35 parts of carbide, 30 parts of silicide, 20 parts of boride, graphite powder 20 parts) into the crucible in...

Embodiment 3

[0047] Step 1: Prepare the working equipment: clean the placed working equipment, power on the device after cleaning, and wait for standby;

[0048] Step 2: Preparation of non-ferrous metal alloy materials: Use a rolling device to carry out deep rolling on graphite powder and other materials, then pass the rolled material powder through the screening machine for screening, and use the collection box to collect the rolled and screened materials stand up;

[0049] Step 3: Mix the proportioned materials (ie: 15 parts of elemental tin, 30 parts of elemental nickel, 12 parts of copper oxide, 10 parts of metal magnesium ore soil, 20 parts of cobaltite, 40 parts of copper-iron mixture, sodium thiosulfate 20 parts, 25 parts of aluminum sulfate, 30 parts of sodium nitrate, 10 parts of aluminum oxide, 20 parts of potassium chloride, 20 parts of phosphorus, 50 parts of stearic acid, 50 parts of carbide, 40 parts of silicide, 30 parts of boride, graphite 30 parts of powder) into the cruc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com