A kind of deformed superalloy containing zr-ce and preparation method thereof

A technology for deforming superalloys and alloys, which is applied in the field of superalloy smelting, and can solve the problems of unreasonable and accurate control of Zr smelting process, element burning loss, complex control of Zr and Ce elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

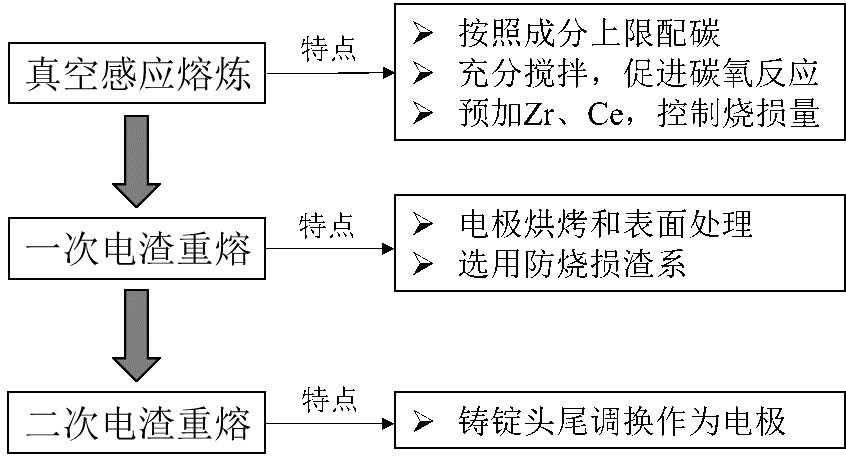

[0035] In a first aspect, the present invention provides a method for preparing a deformed superalloy containing Zr-Ce, said method comprising the steps of:

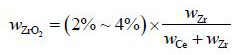

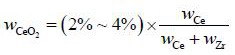

[0036] (1) Provide raw materials for preparing deformed superalloys containing Zr-Ce, the raw materials include matrix element raw materials and adjustment element raw materials, and the adjustment element raw materials include zirconium raw materials and cerium raw materials; in the present invention, the described raw materials containing The deformed superalloy of Zr-Ce refers to the deformed superalloy containing trace elements Zr and Ce at the same time; the present invention has no special requirements on the raw materials, and adopts the existing raw materials commonly used in the preparation of deformed superalloys and the composition ratio of each raw material In the present invention, taking the GH4710 deformed superalloy containing Zr-Ce as an example, the matrix element raw materials include, for example, chro...

Embodiment 1

[0061] This embodiment provides a method for preparing a Zr—Ce-containing GH4710 alloy, and the target content values of each component in the GH4710 alloy are shown in Table 1 below.

[0062]

[0063] Described preparation method comprises the steps:

[0064] ①Equipment and material preparation: A 1t vacuum induction furnace is used to prepare raw materials according to the target composition ratio, among which electrode carbon (C) is prepared according to the total mass of GH4710 alloy containing Zr-Ce at 0.1%, sponge zirconium and cerium particles are prepared according to the target content value 110% preparation, that is, the preparation amount of sponge zirconium is 3.3% of the total mass of Zr-Ce-containing GH4710 alloy, and the preparation amount of cerium particles is 2.2% of the total mass of Zr-Ce-containing GH4710 alloy.

[0065] ②Chemical material stage: first add nickel plate, cobalt plate, tungsten strip, electrode carbon, and molybdenum block in proportion...

Embodiment 2

[0071] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0072] ②Chemical material stage: Add nickel plate, chromium block, cobalt plate, tungsten bar, electrode carbon, and molybdenum block at a time according to the proportion, vacuumize to 20Pa, and smelt with electricity. After melting, stir for 15 minutes to obtain the molten material to be refined.

[0073] Drilling chips at the head, middle and tail of the Zr-Ce-containing GH4710 alloy obtained in this embodiment, the specific positions are 50mm from the ingot head, 50mm from the ingot middle, and 50mm from the ingot tail, and detect the GH4710 alloy The Zr, Ce, N, and O contents at the head, middle, and tail positions are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com