Lithium ion solid electrolyte with core-shell structure and preparation method

A technology of solid electrolyte and core-shell structure, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of unsatisfactory conductivity and narrow electrochemical window, and achieve cycle life without pollution, high energy density, Effect of preventing electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

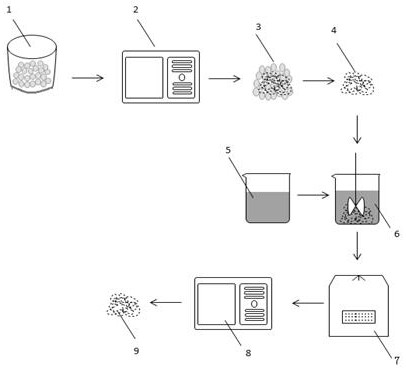

Method used

Image

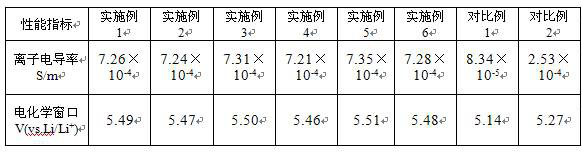

Examples

Embodiment 1

[0039] (1) Put Li first 2 CO 3 、Al 2 o 3 、TiO 2 and NH 4 h 2 PO 4 , mixed evenly, then added to an alumina crucible, calcined in a muffle furnace I, and then naturally cooled to room temperature to obtain a core material powder, and finally the powder was ground and sieved to obtain a core layer powder; the calcined temperature was 780℃, the time is 5h; the core material powder is Li 1.1 al 0.1 Ti 1.9 (PO 4 ) 3 ; The mesh number of sieving is 800 mesh;

[0040] The ratio of each raw material is, by mole, Li 2 CO 3 1.1 moles, Al 2 o 3 0.1 mole, TiO 2 3.8 moles, NH 4 h 2 PO 4 6 moles;

[0041] (2) LiOH·H 2 O, H 3 BO 3 , NH 4 h 2 PO 4 and NH 4 Add F into deionized water, then stir until fully dissolved, then use ammonia water to adjust the pH value, and react to obtain Li 0.15 B 0.95 (PO 4 ) 0.9 f 0.3 Precursor, then add silica sol, and finally mechanically stir to obtain the sol; adjust the pH value to 8.5; the silica sol is alkaline silica so...

Embodiment 2

[0048] (1) Put Li first 2 CO 3 、Al 2 o 3 、TiO 2 and NH 4 h 2 PO 4 , mixed evenly, then added to an alumina crucible, calcined in a muffle furnace, and then naturally cooled to room temperature to obtain a core material powder, and finally the powder was ground and sieved to obtain a core layer powder; the calcined temperature was 750 ℃, the time is 5.5h; the core material powder is Li 1.1 al 0.1 Ti 1.9 (PO 4 ) 3 ; The mesh number of sieving is 900 mesh;

[0049] The ratio of each raw material is, by mole, Li 2 CO 3 1.1 moles, Al 2 o 3 0.1 mole, TiO 2 3.8 moles, NH 4 h 2 PO 4 6 moles;

[0050] (2) LiOH·H 2 O, H 3 BO 3 , NH 4 h 2 PO 4 and NH 4 Add F into deionized water, then stir until fully dissolved, then use ammonia water to adjust the pH value, and react to obtain Li 0.15 B 0.95 (PO 4 ) 0.9 f 0.3 Precursor, then add silica sol, and finally mechanically stir to obtain sol; adjust pH to 8; silica sol is alkaline silica sol with a solid cont...

Embodiment 3

[0056] (1) Put Li first 2 CO 3 、Al 2 o 3 、TiO 2 and NH 4 h 2 PO 4 , mixed evenly, then added to an alumina crucible, calcined in a muffle furnace, and then naturally cooled to room temperature to obtain a core material powder, and finally the powder was ground and sieved to obtain a core layer powder; the calcining temperature was 850 ℃, the time is 4.5h; the core material powder is Li 1.1 al 0.1 Ti 1.9 (PO 4 ) 3 ; The mesh number of sieving is 900 mesh;

[0057] The ratio of each raw material is, by mole, Li 2 CO 3 1.1 moles, Al 2 o 3 0.1 mole, TiO 2 3.8 moles, NH 4 h 2 PO 4 6 moles;

[0058] (2) LiOH·H 2 O, H 3 BO 3 , NH 4 h 2 PO 4 and NH 4 Add F into deionized water, then stir until fully dissolved, then use ammonia water to adjust the pH value, and react to obtain Li 0.15 B 0.95 (PO 4 ) 0.9 f 0.3 Precursor, then add silica sol, and finally mechanically stir to obtain the sol; adjust the pH value to 8; the silica sol is alkaline silica so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com