Simple blow-molding tray

A kind of pallet and simple technology, applied in the field of plastic products, can solve the problems of detachment of plunger, damage of goods falling, single function, etc., and achieve the effect of increasing friction, preventing prolapse and good clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

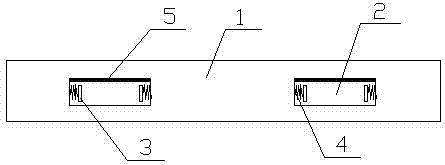

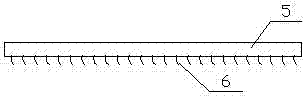

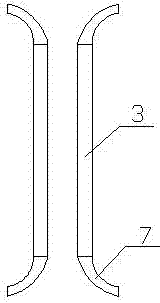

[0016] Such as Figure 1~3 As shown, a simple blow-molded pallet includes a pallet body 1 provided with two sockets 2 for the insertion of the forklift rod. The inner walls on both sides of the socket 2 are elastically connected with splints 3 for clamping the forklift rod. Through the socket 2, and the end of the splint 3 is provided with an extended arc-shaped plate 7, and the arc-shaped plate 7 extended at the end of the splint 3 on both sides constitutes a bell mouth for the forklift rod to extend into, and the splint 3 passes through the self-rebound spring 4 It is elastically connected with the inner wall of the socket 2, and the self-rebound spring 4 is fixedly connected with the splint 3 at both ends and the inner wall of the socket 2 through positioning bolts. The upper edge of the socket 2 is bonded with a silicone plate 5, which is evenly distributed on the silicone plate 5 to increase Frictional barbs6.

[0017] During installation and use, the arc-shaped plate 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com