Power supply clamping position ESD (electronic static discharge) protecting circuit

An ESD protection and circuit technology, applied in the field of clamping circuits, can solve problems such as false triggering of ESD clamping circuits, and achieve the effects of avoiding false triggering, reducing leakage current, and improving clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

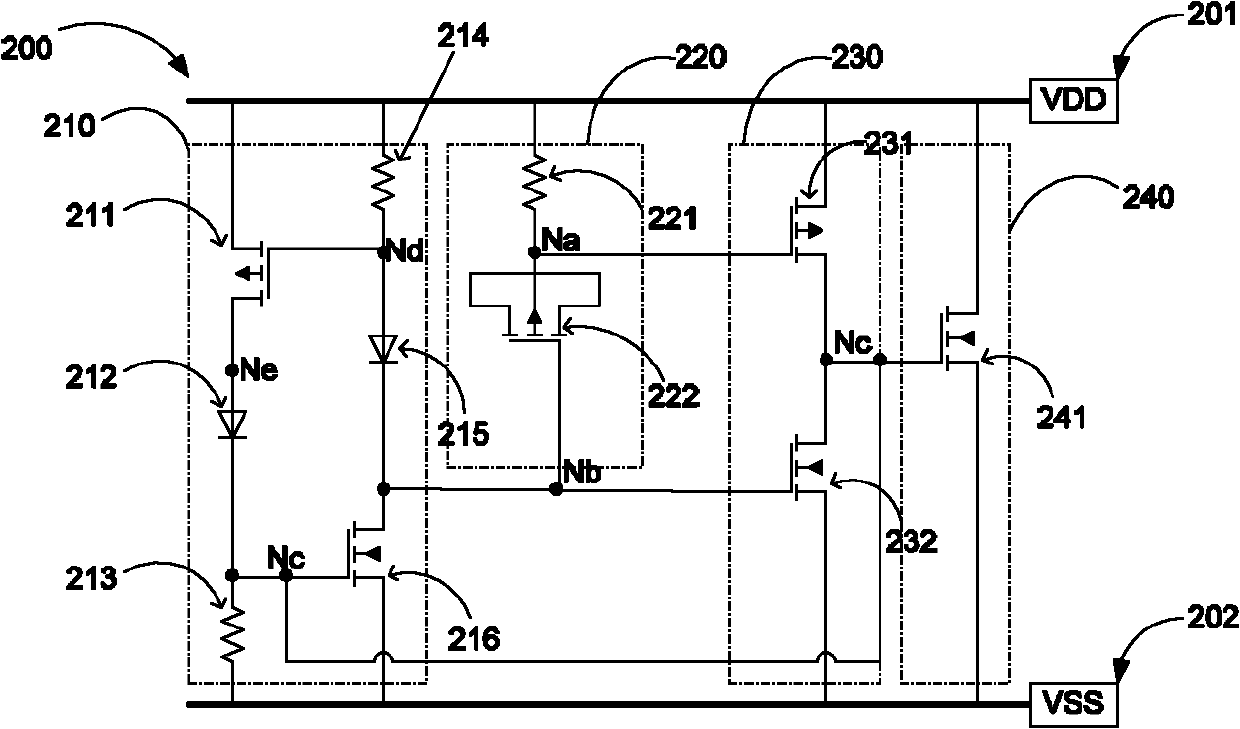

[0043] The core idea of the present invention is that the ESD detection circuit is not directly connected to the ground (VSS), but indirectly coupled to VSS through a bias circuit. By using the bias circuit, the voltage difference between the two ends of the MOS capacitor becomes very small, thereby reducing the leakage current of the MOS capacitor, thereby suppressing the subthreshold leakage of other MOS transistors in the ESD protection circuit.

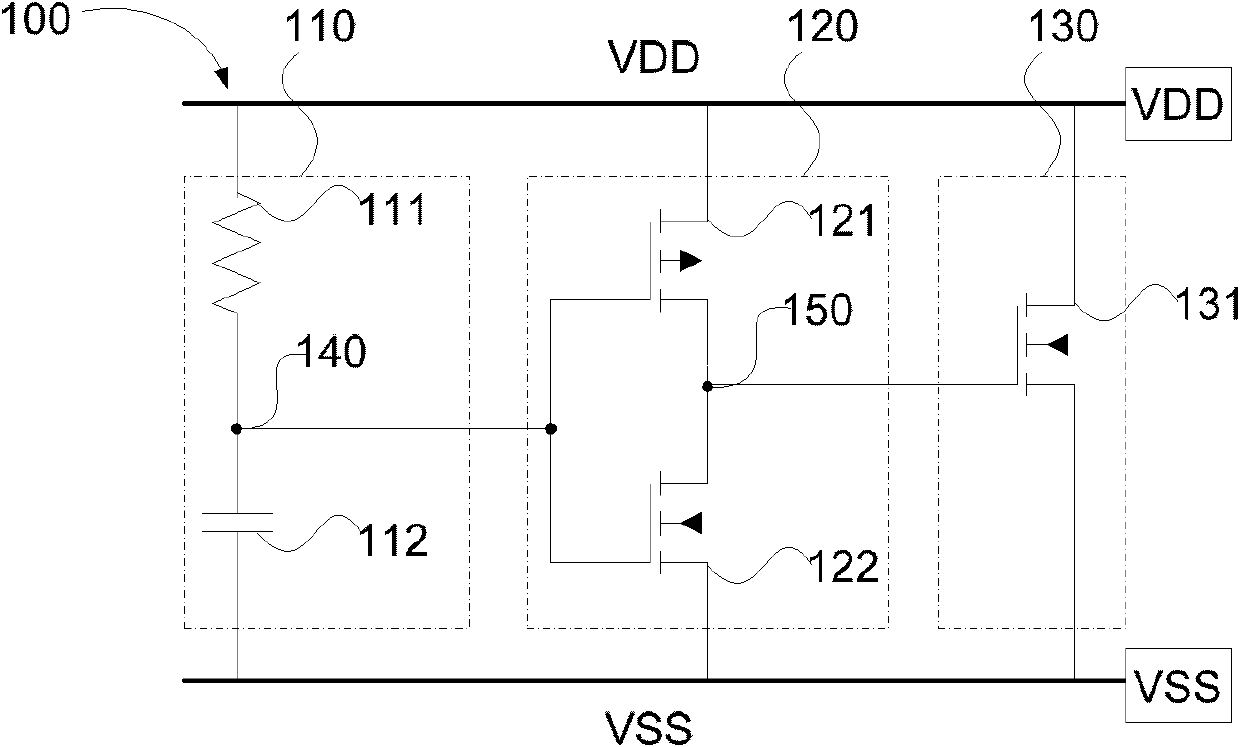

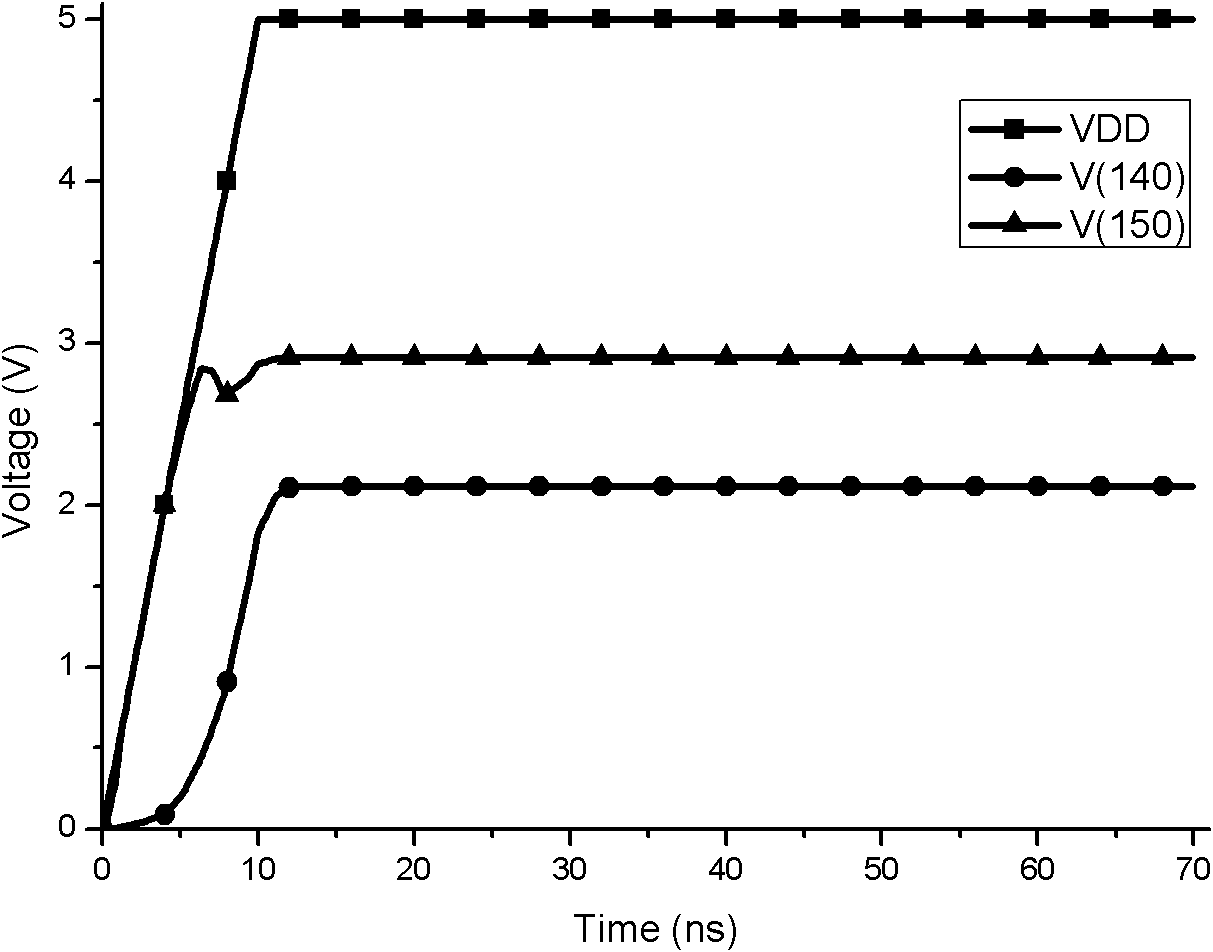

[0044] Therefore, the present invention provides a power clamp ESD protection circuit, which includes: a power pin VDD, a ground pin VSS, and an ESD detection circuit coupled between the power pin VDD and the ground pin VSS. with conventional ESD detection circuits (such as figure 1The difference between the ESD detection circuit 100) in the present invention is that the ESD detection circuit in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com