Electric-driven type mechanical hand claw

A manipulator claw, electric technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of high cost, complexity, and impracticality of gripping light objects, and achieve the effect of simple structure setting and good gripping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

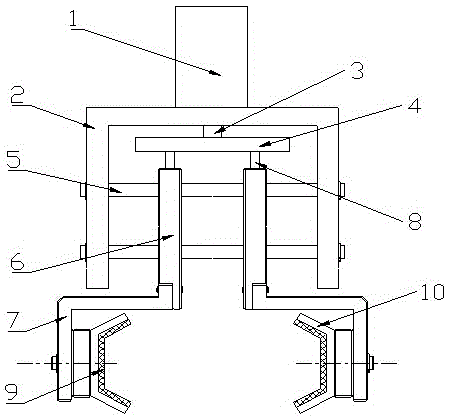

[0018] like figure 1 and figure 2 As shown, the present invention discloses an electric manipulator gripper, comprising a three-phase asynchronous motor 1 , a mounting plate 2 arranged at the lower end of the motor, and an actuator connected to the motor shaft 3 .

[0019] The mounting plate 2 is N-shaped and includes an upper top plate and two side plates, the middle of the upper top plate is fixedly connected to the three-phase asynchronous motor 1, and an actuator is arranged in the cavity at the lower end.

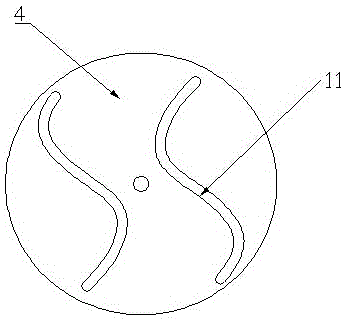

[0020] The actuator includes a rotating plate 4 connected with the motor shaft 3, a pair of parallel guide posts 5 arranged at the lower end of the rotating plate 4, a pair of sliding blocks 6 inserted into the pair of parallel guide columns 5, and a pair of sliding blocks arranged on the pair of sliding blocks. 6. A pair of V-shaped claws 10 at the lower end; the rotating plate 4 is circular, the middle part is fixed on the motor shaft 3, and a pair of symmetrical S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com