Pin joint structure for universal joint

A universal joint and pivot joint technology, which is applied in the field of universal joint pivot joint structure, can solve the problems of loss of working angle, large centrifugal force, and low service life, and achieve the effect of stable pivot joint structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

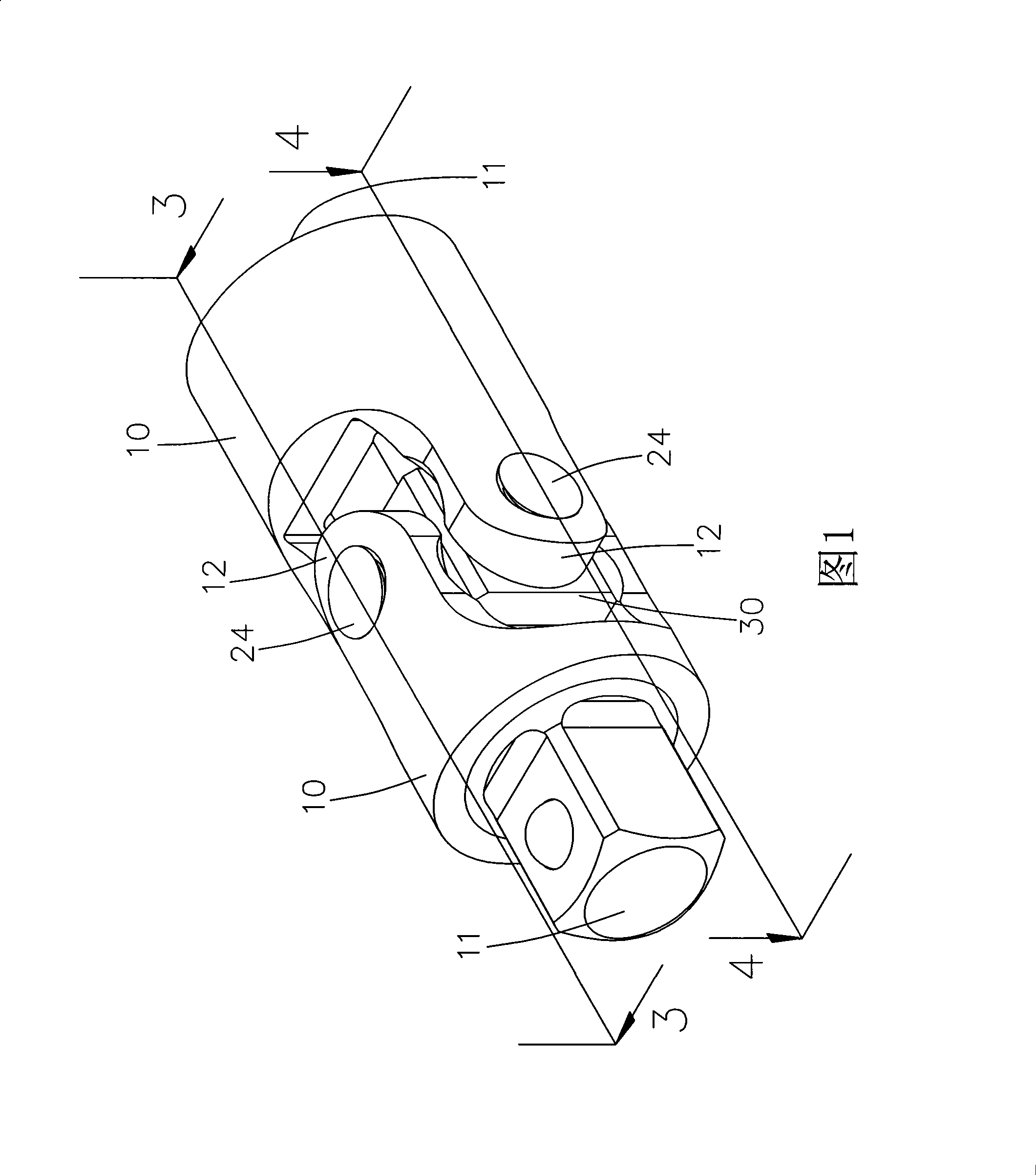

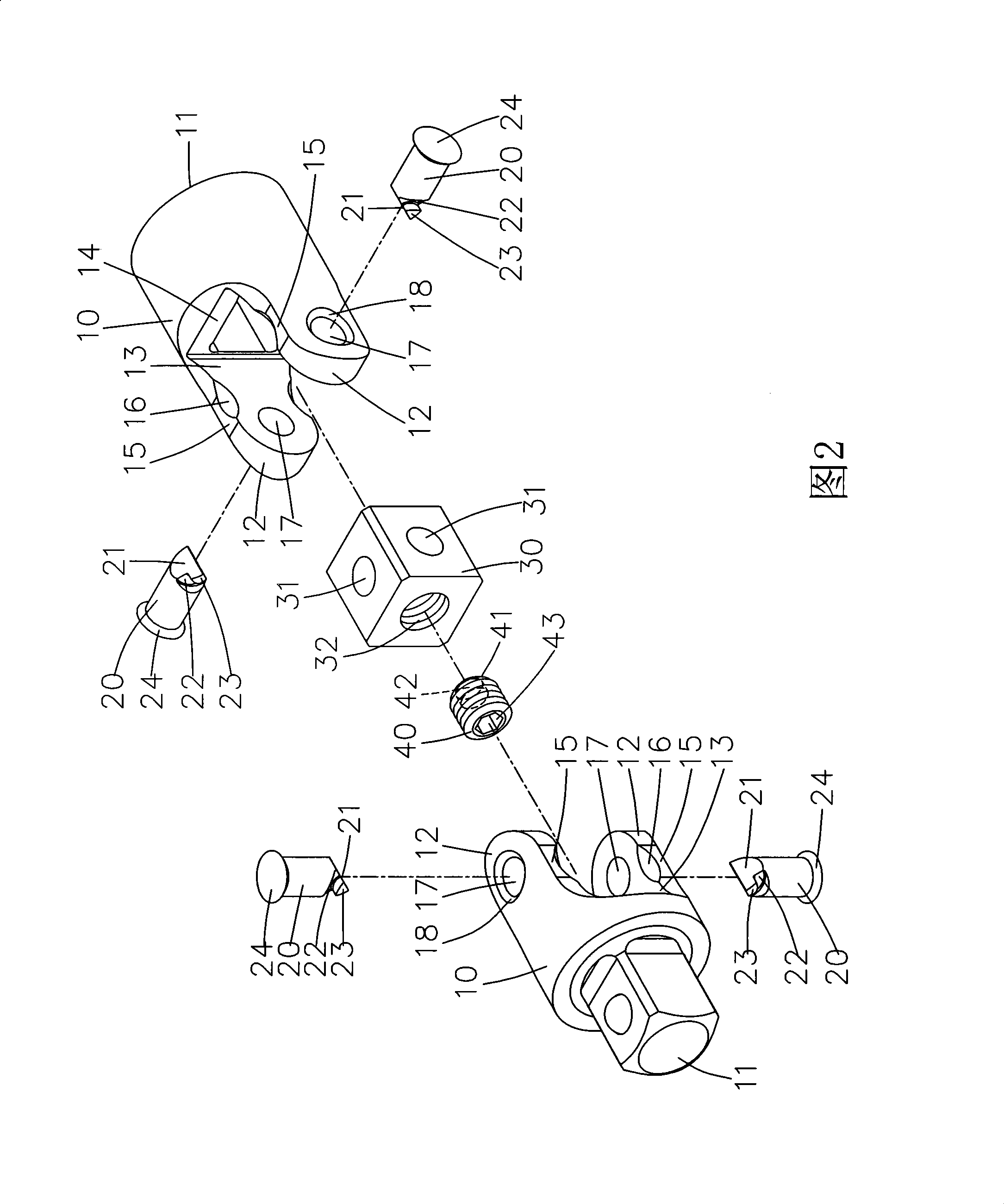

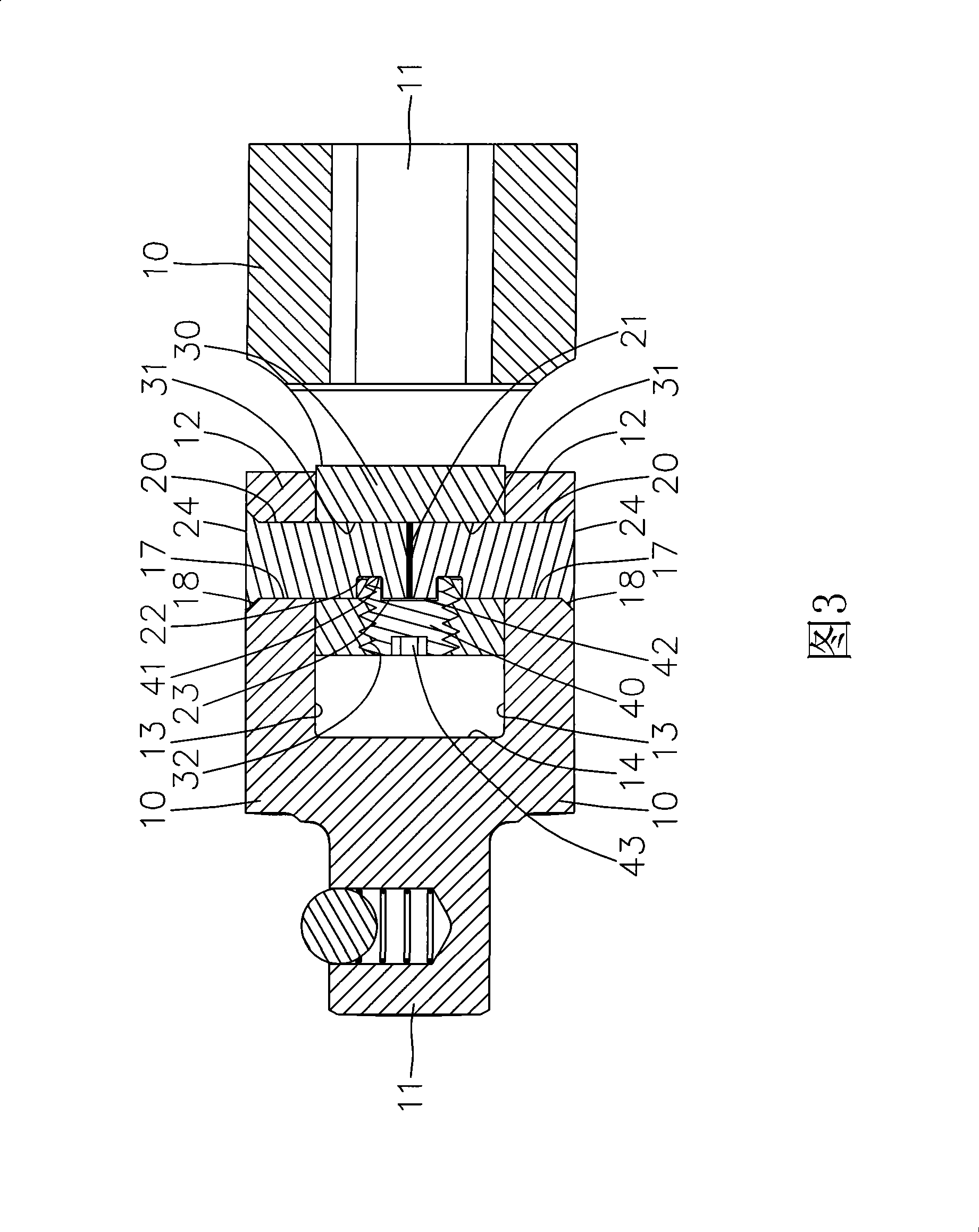

[0025] Referring to FIG. 1 and FIG. 2 , the universal joint of the present invention includes two driving parts 10 , a connecting part 30 pivotally connected between the two driving parts 10 , and a limiting part 40 disposed on the connecting part 30 . A shaft 20 is pivoted between the connecting piece 30 and the two driving pieces 10, and the limiting piece 40 is fastened to the shaft 20, so that the shaft 20 can be firmly connected to the connecting piece 30. Inside, at the same time achieve the effect of detachable.

[0026] One end of the driving element 10 is provided with a coupling end 11 for connecting the driving object or the driven object. The end of the driving member 10 opposite to the connecting end 11 is provided with a pivoting end 12 . Wherein, the coupling end 11 of the driving member 10 can be configured as a sleeve shape or a square head shape, and this change can be easily accomplished by those skilled in the art.

[0027] The pivoting ends 12 of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com