Electroplating production line for vacuum cup

A technology of electroplating production line and thermos cup, which is applied in the direction of electrolysis process and electrolysis components, etc. It can solve the problems of easy damage to the outer wall of the inner tank, the inability to realize the clamping of the inner tank, and affect the production efficiency of electroplating, so as to improve the production efficiency and secure the clamping , good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

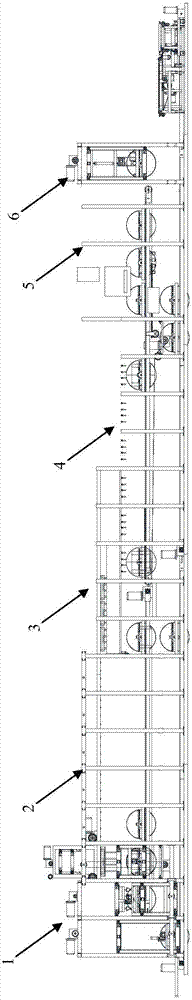

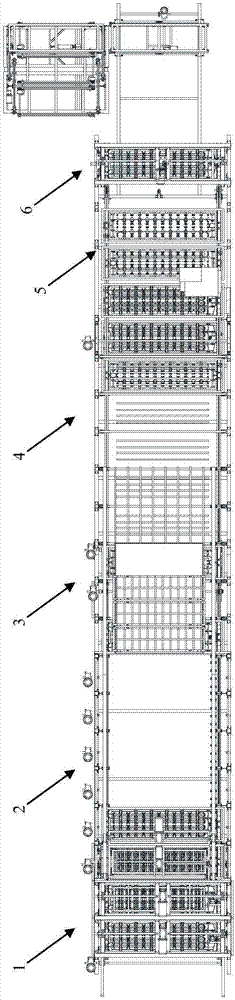

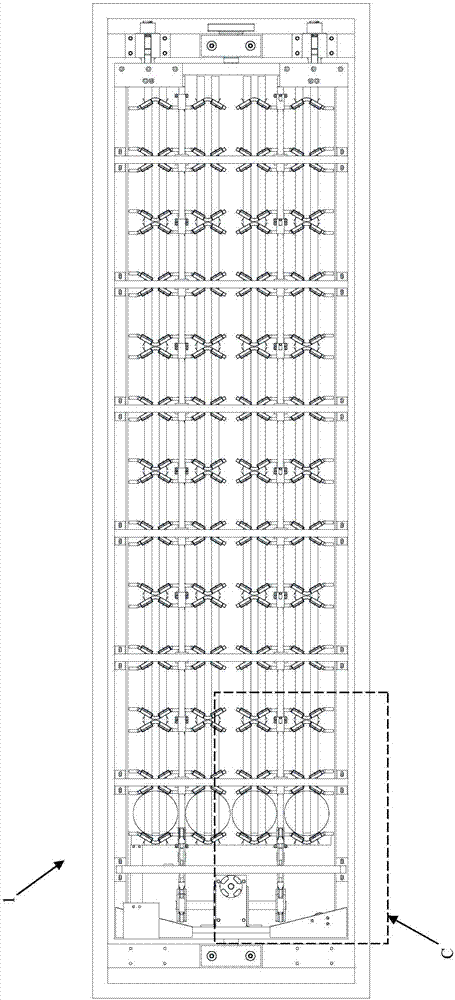

[0017] As shown in the figure, this embodiment provides a thermos cup electroplating production line, including a feeding unit 1, an electrolysis unit 2, a primary water control unit 3, a cleaning unit 4, a secondary water control unit 5, and a drying unit 6. The loading unit includes a clamping mechanism 11; as Figure 5-7 As shown, the clamping mechanism 11 includes a frame body 110, several fixed splint units 111, several movable splint units 112 arranged opposite to the fixed splint unit 111, a fixed rod 113, a movable rod 114 and a driving device, and the fixed splint unit 111 is fixed on the fixed rod 113, the movable splint unit 112 is fixed on the movable rod 114, and the fixed rod 113 is fixedly installed on the frame body 110, and the driving device is connected to the movable rod 114 so as to be able to drive the The movable rod 114 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com