Lime calciner paint liner and forming method thereof

A calciner and coating technology, applied in the field of lime calciner lining body and its molding, can solve the problems of difficult construction quality assurance, troublesome repair work, long construction period, etc., and achieve simple molding method, efficient molding quality, and improved quality and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

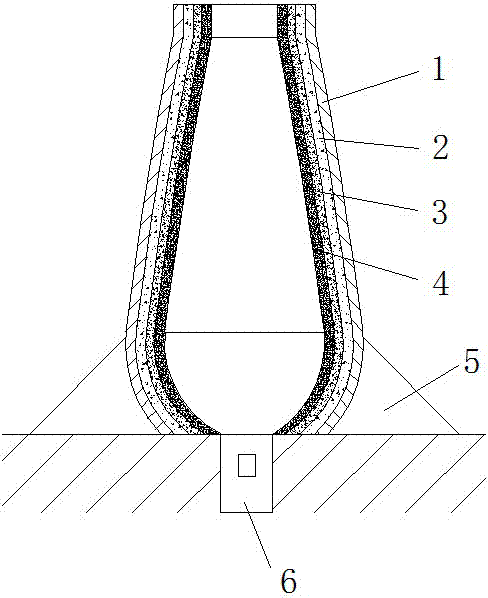

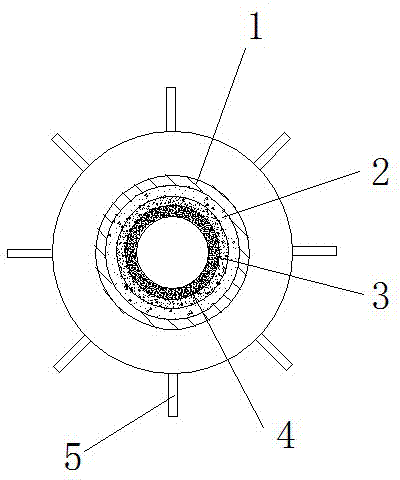

[0027] The thickness of the thermal insulation coating layer 2 is 80 mm, the thickness of the intermediate lining coating layer 3 is 250 mm, and the thickness of the working coating layer 4 is 450 mm.

[0028] The forming method of the inner lining body of the coating layer of the lime calciner comprises the following process steps:

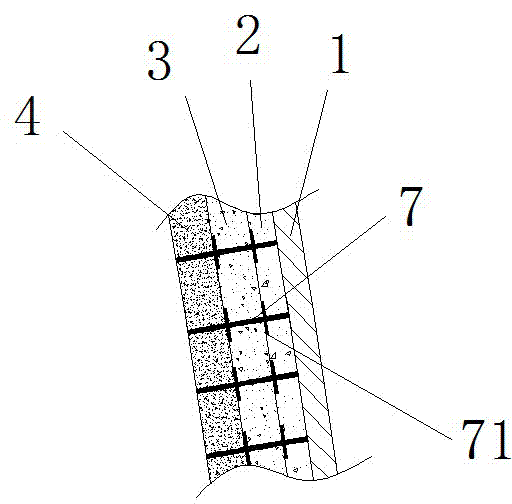

[0029] 1. A number of paint anchors 5 are evenly distributed on the inner wall of the lime calciner shell. The length of the paint anchors 5 is slightly smaller than the total thickness of the lining of the lime calciner, and the paint anchor 7 corresponds to the thermal insulation coating layer in the length direction of the paint anchor 7. The thickness of the body 2 and the intermediate lining paint layer body 3 is provided with a marker 71, and the marker 71 of this embodiment is a connecting short rod perpendicular to the axial direction of the anchor 7;

[0030] 2. Clean the inner wall of the lime calciner shell to remove dust, rust, oil, e...

Embodiment 2

[0035] The thickness of the thermal insulation coating layer 2 is 70 mm, the thickness of the intermediate lining coating layer 3 is 230 mm, and the thickness of the working coating layer 4 is 380 mm.

[0036] The forming method of the inner lining body of the coating layer is basically the same as that of Example 1, except that in step 3, the component raw materials of the coating are first added to the mixer, and a small amount of water is sprayed into the mixer while stirring and mixing to pre-wet, so as to facilitate dust reduction in the working environment , Then the mixture that is fully mixed and less floating dust is added in the feed hopper of the pneumatic rotary spray gun, and all the other procedures are the same as in Example 1.

[0037] Example 3, a lime calciner, the furnace body is in the shape of a vase with a large middle and two small ends, with a height of 13m and a maximum inner diameter of 4m. A number of radial paint anchors 7 on the inner wall of the h...

Embodiment 3

[0038] The thickness of the above-mentioned thermal insulation coating layer 2 is 60 mm, and the thickness of the intermediate lining coating layer 3 plus the working coating layer 4 is 500 mm.

[0039] The forming method of the inner liner of the paint layer is the same as that in Example 2.

[0040] Example 4, the repair of partial damage to the inner lining of the coating layer of the lime calciner or the working layer of the inner lining formed by refractory casting. Specific steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com