Numerical control abrasive belt grinding machine with six-axis linkage

A belt grinder and six-axis linkage technology, which is applied in the direction of belt grinder, grinder, grinding bed, etc., to achieve the effect of good surface quality consistency, low labor intensity of workers, and reduced floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0158] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

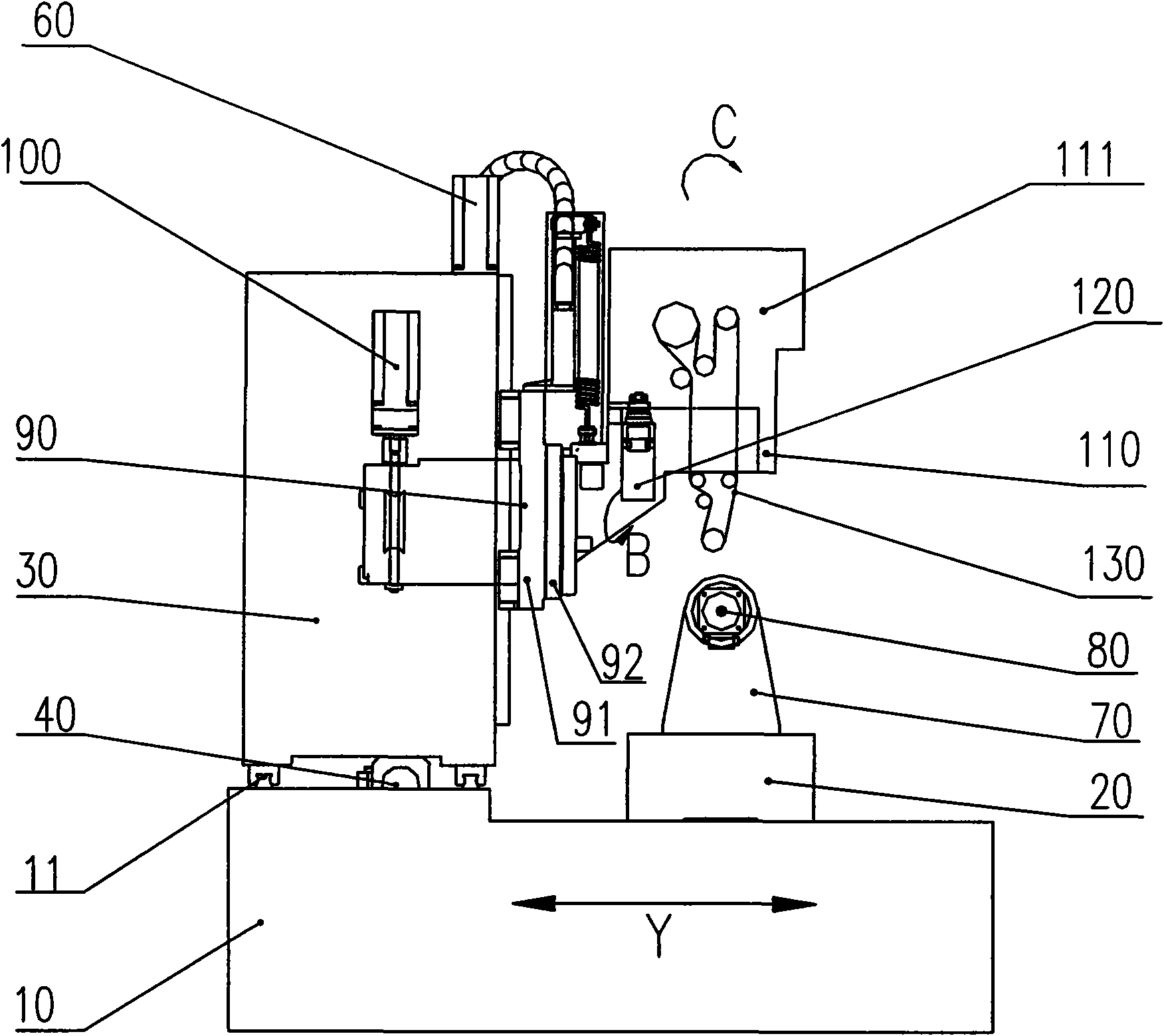

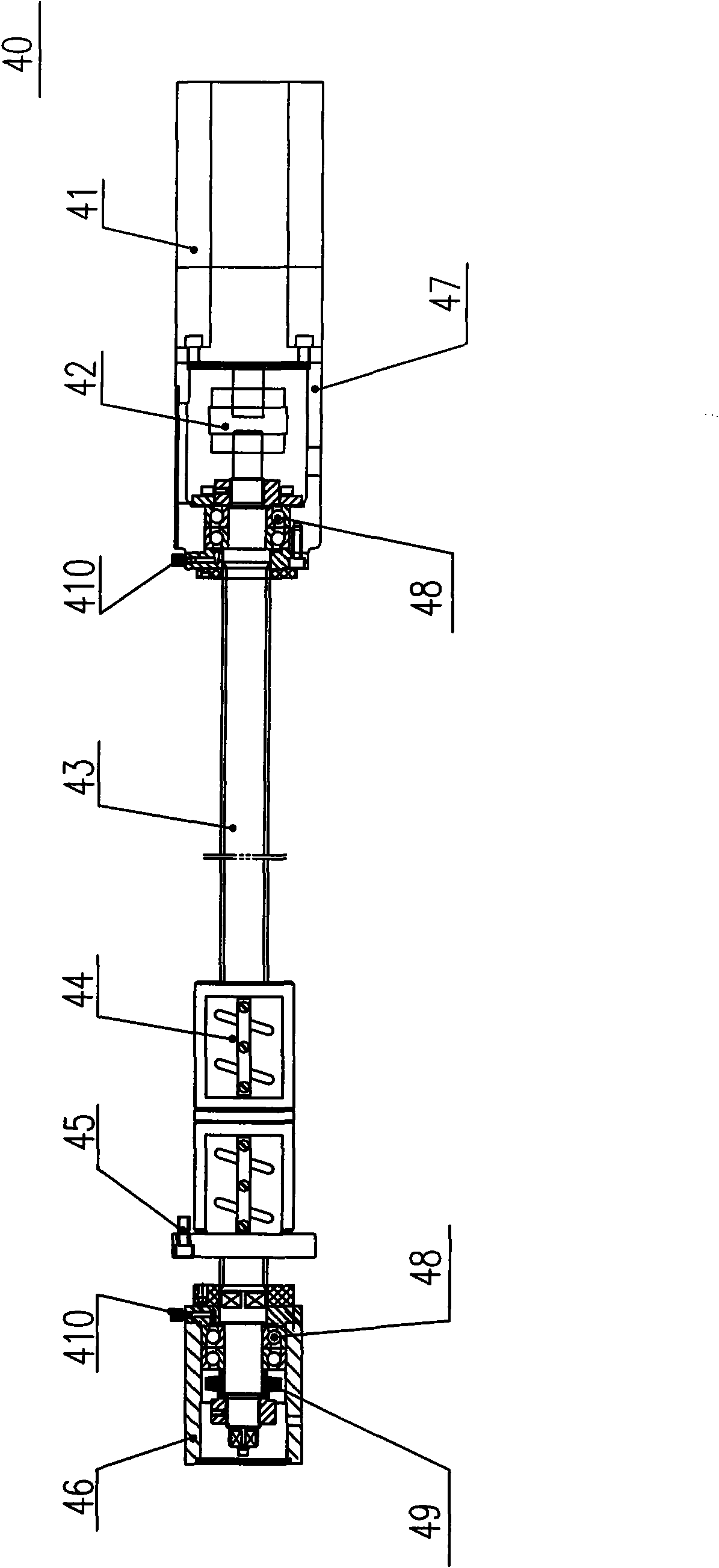

[0159] see figure 1 and figure 2 , as shown in the figure, the six-axis linkage CNC abrasive belt grinder of the present invention includes a bed 10, a worktable 20, a column component 30, an X-axis drive system 40, a Y-axis drive system 50, a Z-axis drive system 60, and an A-axis Component 70, A-axis drive system 80, B-axis component 90, B-axis drive system 100, C-axis component 110, C-axis drive system 120, belt sander 130 and numerical control system, the numerical control system is not shown in the figure.

[0160] Wherein, the bed 10 is provided with X-axis guide rails 11 and Y-axis guide rails 12 perpendicular to each other, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com