Product display hanger and process

a technology for hanging racks and products, applied in the field of product hangers, can solve the problems of pressure-sensitive hangers peeling from the surface, and the packaging system uses a considerable amount of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

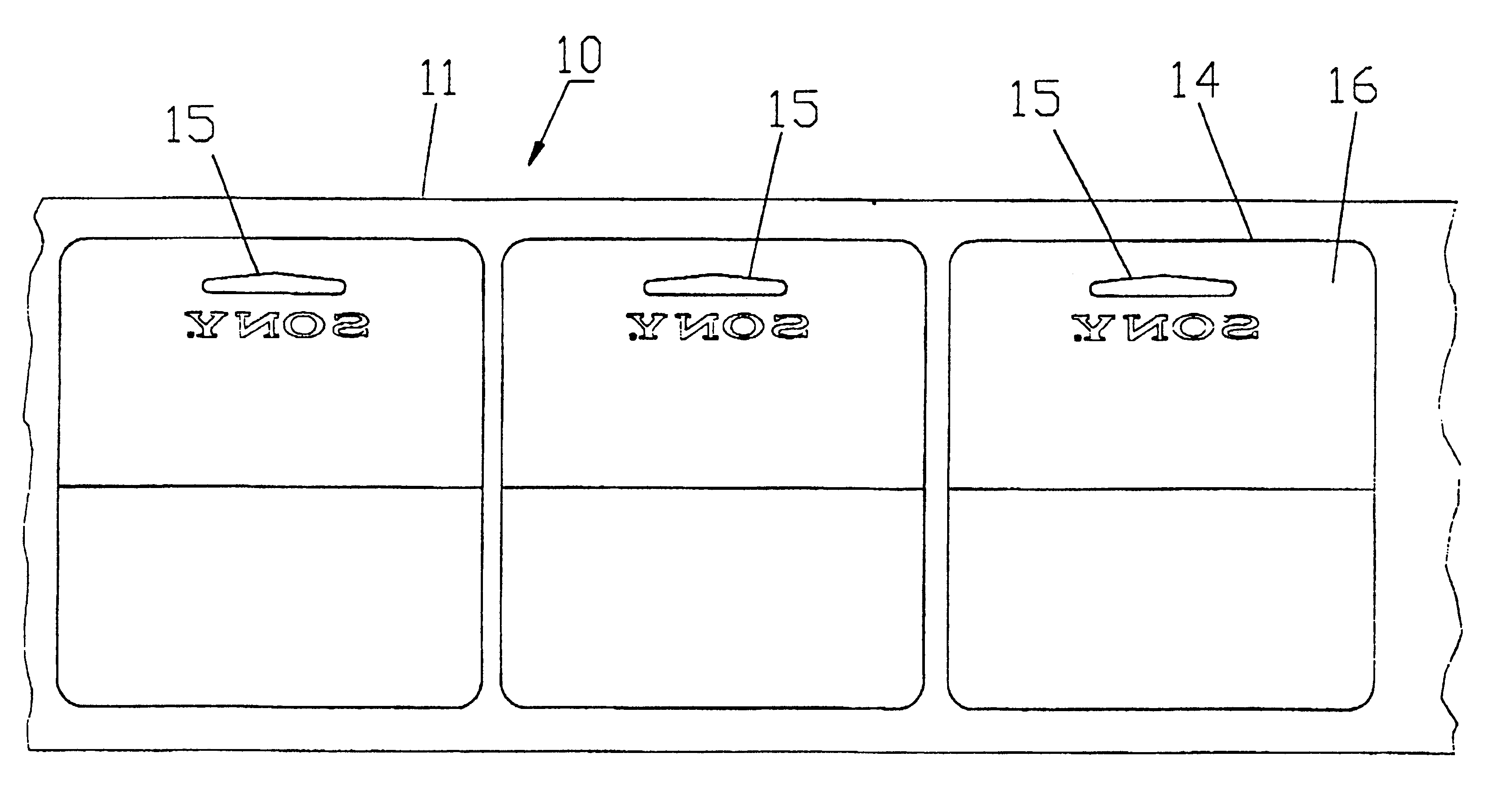

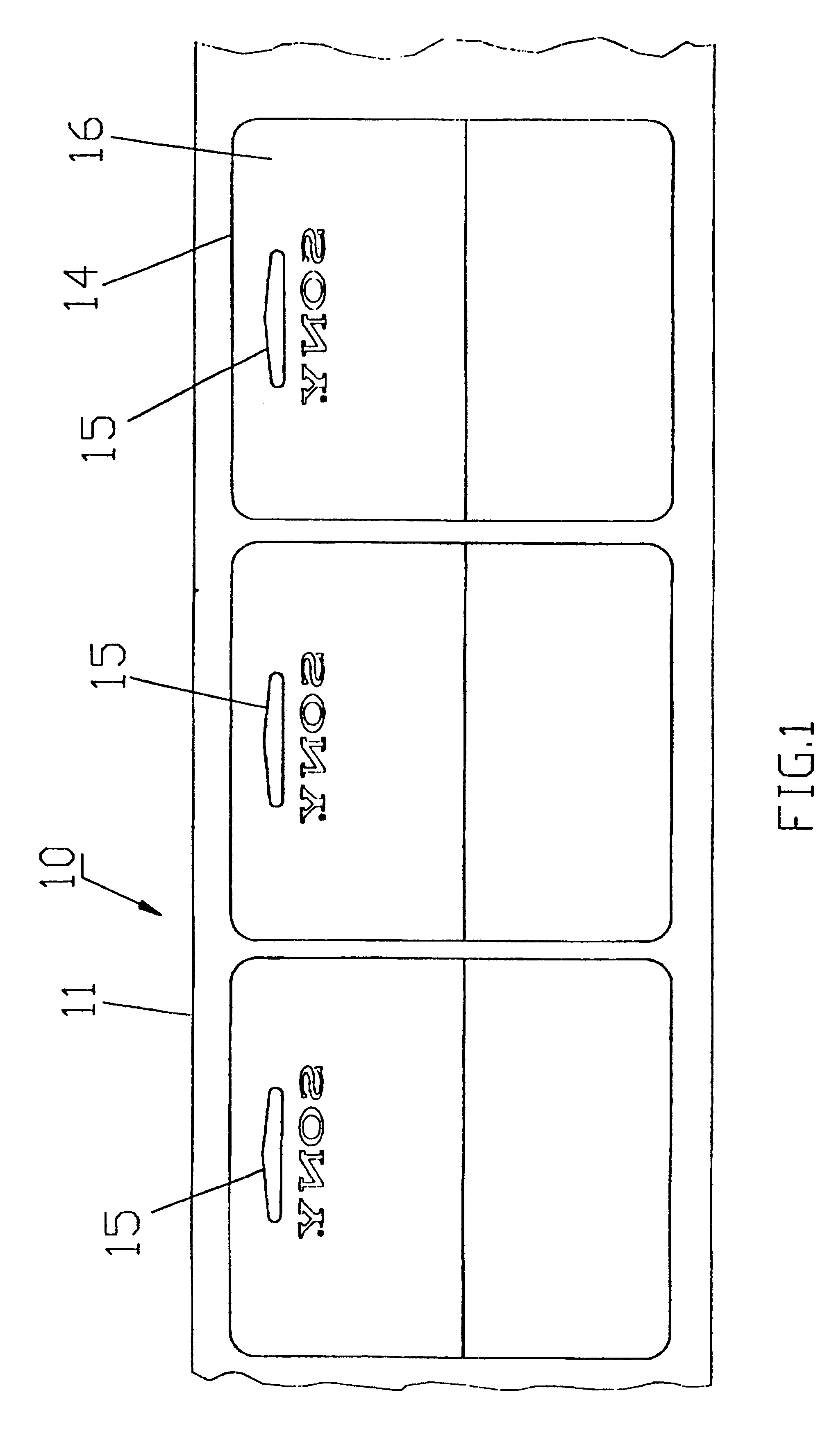

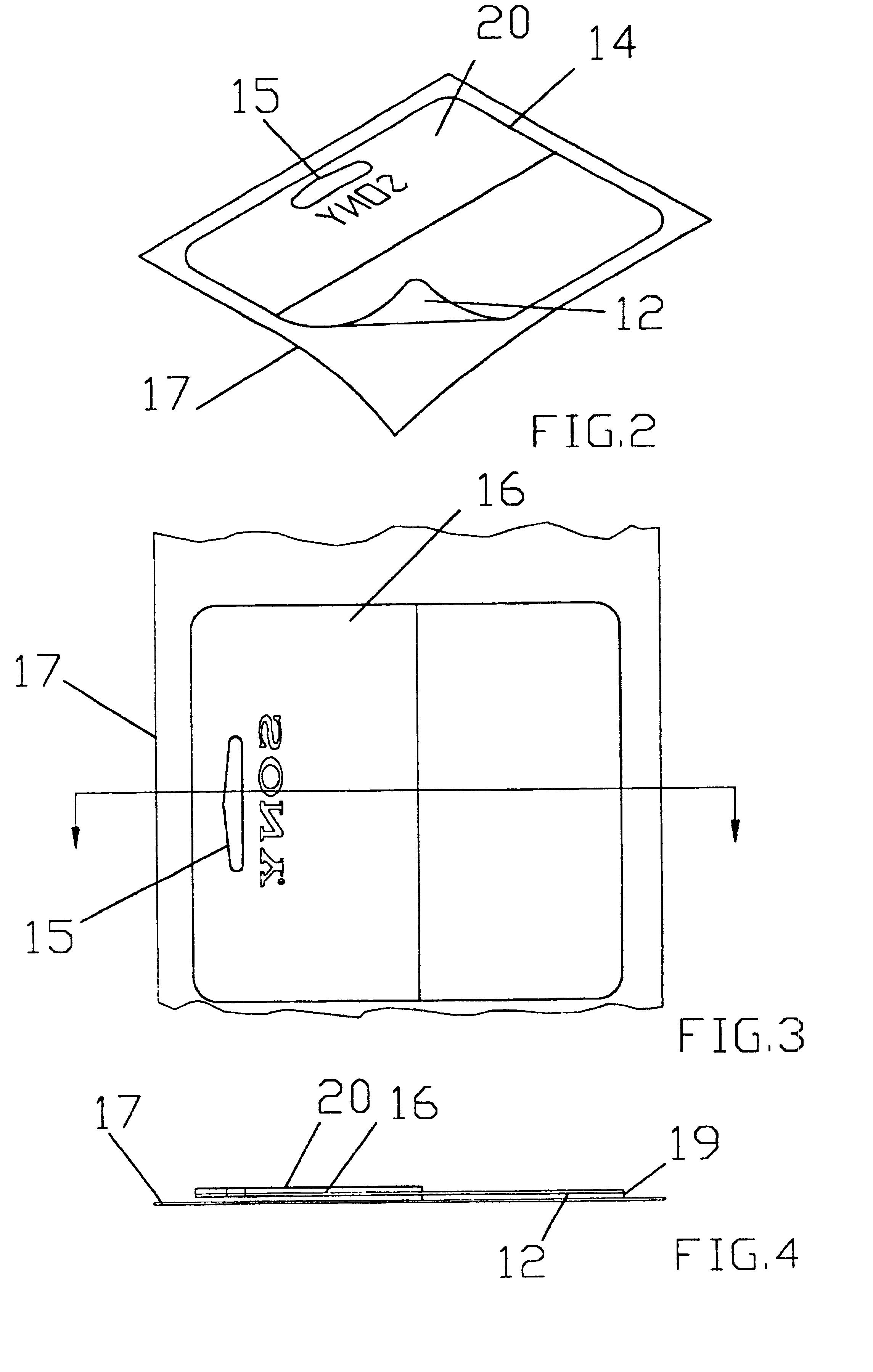

The invention comprises a new and novel hang tag 10, having a billboard label containing graphics for sales display, a hanging system for suspending a package of tightly wrapped (shrink wrap) products from a single wire hanger and / or a double wire hanger, and a method of manufacturing hang tags on a multi-color web press.

The hang tag 10 of the invention is preferably formed of a clear, polyester resin face stock 11 having an adhering region on a front side, lower portion 12 where an adhesive is applied to adhere hang tag 10 to an object or package 13, and a hanging region 14 on the upper portion with die cut opening 15 where hang tag 10 can be hung on single or double wire hangers, and a back side upper portion 16 where a billboard containing graphics may be printed for sales display. Die cut opening 15 may remain attached to hang tag 10 by leaving two small uncut attachments (not shown) to permit removal only when required. Normally, merely pushing out the die cut opening 15 is suf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| water soluble | aaaaa | aaaaa |

| pressure- | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com