No-body-paper label as well as process method and label roll thereof

A linerless, label roll technology, used in stamps, instruments, identification devices, etc., can solve the problems of waste, thick labels, and high label costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

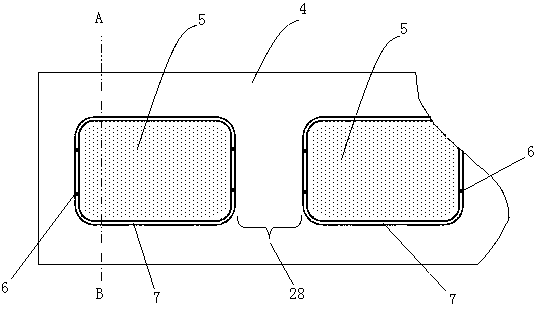

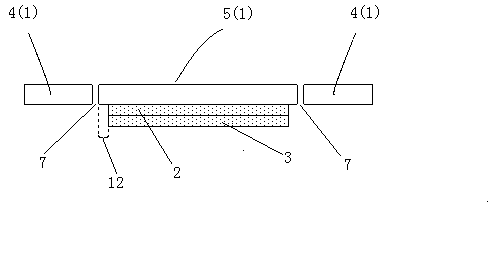

[0100] First, if figure 1 , figure 2 , image 3 , Figure 4 As shown, a 1000-meter-long, 12-micron-thick PET transparent film roll is selected as the base tape layer (1) roll, and ink layers (2) such as logos and texts are printed on the inner surface.

[0101] Then, print pieces of hot-melt adhesive as the adhesive layer (3) on each identification graphic ink layer (2). The adhesive layer (3) formed by the hot melt adhesive is dry and solid at normal temperature. The adhesive applied on the back of the existing bronzing film can be used as the hot melt adhesive of this example.

[0102] Afterwards, pre-die cutting, so that the base tape layer (1) is die-cut and divided into a continuous reelable waste unit (4) and a plurality of 38mm×58mm labels lined up with a distance H (28) of 7mm unit (5), and the waste unit (4) and each label unit (5) are connected together to form a A technical structure with disconnected links. Here, the connection line (6) should be kept as n...

Embodiment 2

[0107] First, see image 3 , choose a 1000-meter-long, 35-micron-thick PET transparent film roll as the base tape layer (1), and print the necessary text, pattern and other ink layers (2) on the inner surface of the film.

[0108] Then, a 25 μm thick glue microcapsule layer is fully coated on the ink layer (2) and the inner surface of the film as the adhesive layer (3).

[0109] Afterwards, pre-die cutting, so that the base tape layer (1) roll is die-cut and divided into a continuous reelable waste unit (4) and a plurality of 38mm×58mm with a distance H (28) of 7mm lined up The label unit (5), and the waste unit (4) and each label unit (5) are connected together through the reserved multiple 0.05mm wide connecting lines (6))—that is, the uncut parts Form a technical structure that is disconnected and disconnected.

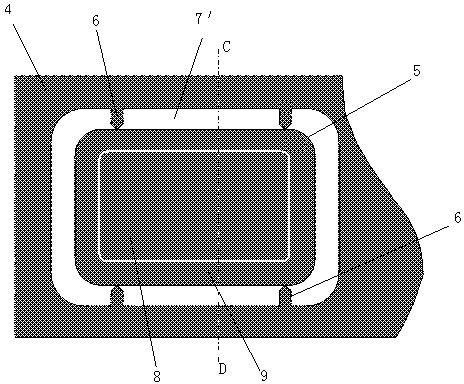

[0110] To avoid the hot stamping plate pressing against the waste unit (4) due to mechanical errors, such as image 3 As shown, a gap window (7') with a width o...

Embodiment 3

[0117] First, if image 3 , Figure 4 As shown, choose a 1000-meter-long, 48g / m 2 The light-weight coated paper roll material is used as the base tape layer (1) roll, and the ink layer (2) such as necessary characters and patterns is printed on the front side.

[0118] Then, a 34mm×54mm low-temperature hot-melt adhesive with a melting point of 80°C is printed on the middle area (8) of the back of the label as an adhesive layer (3). And a 3 mm wide high-temperature hot melt adhesive with a melting point of 140° C. is printed on the label edge area ( 9 ) as the adhesive layer ( 3 ).

[0119] Afterwards, pre-die cutting, so that the base tape layer (1) is die-cut and divided into a continuous reelable waste unit (4) and a plurality of 38mm×58mm labels lined up with a distance H (28) of 20mm unit (5), and between the waste unit (4) and each label unit (5), respectively through the reserved multi-section 0.05mm wide connection line (6)) - that is, the uncut part, connected toget...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com