Two-sided conductive fabric adhesive tape and production technology thereof

A production process and technology of conductive cloth, applied in the field of conductive cloth tape, can solve problems such as difficult to tear, and achieve the effect of reducing wool and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

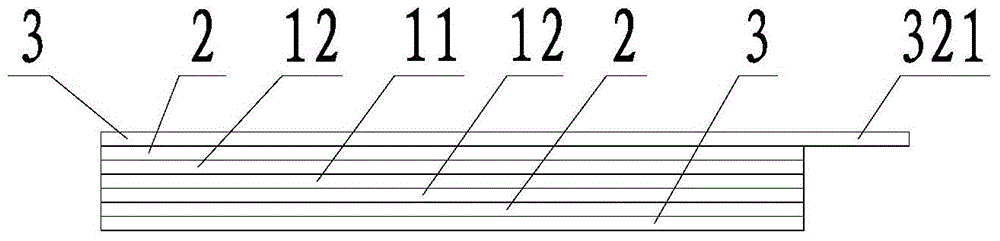

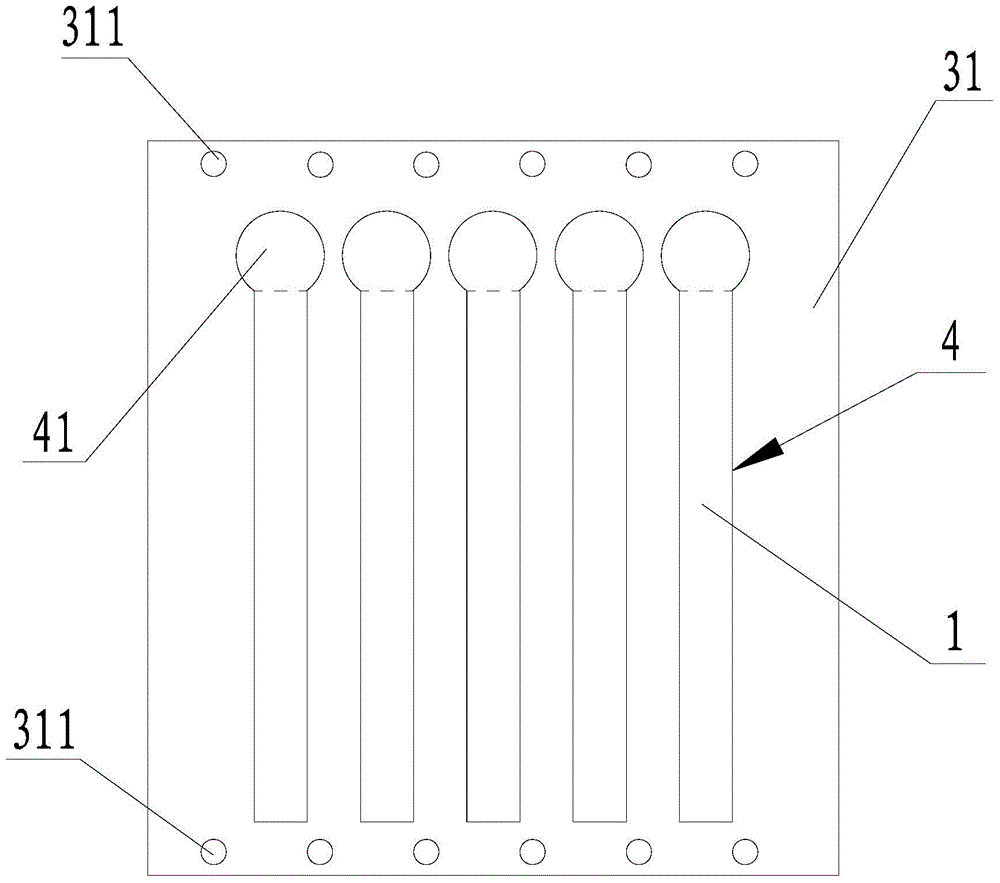

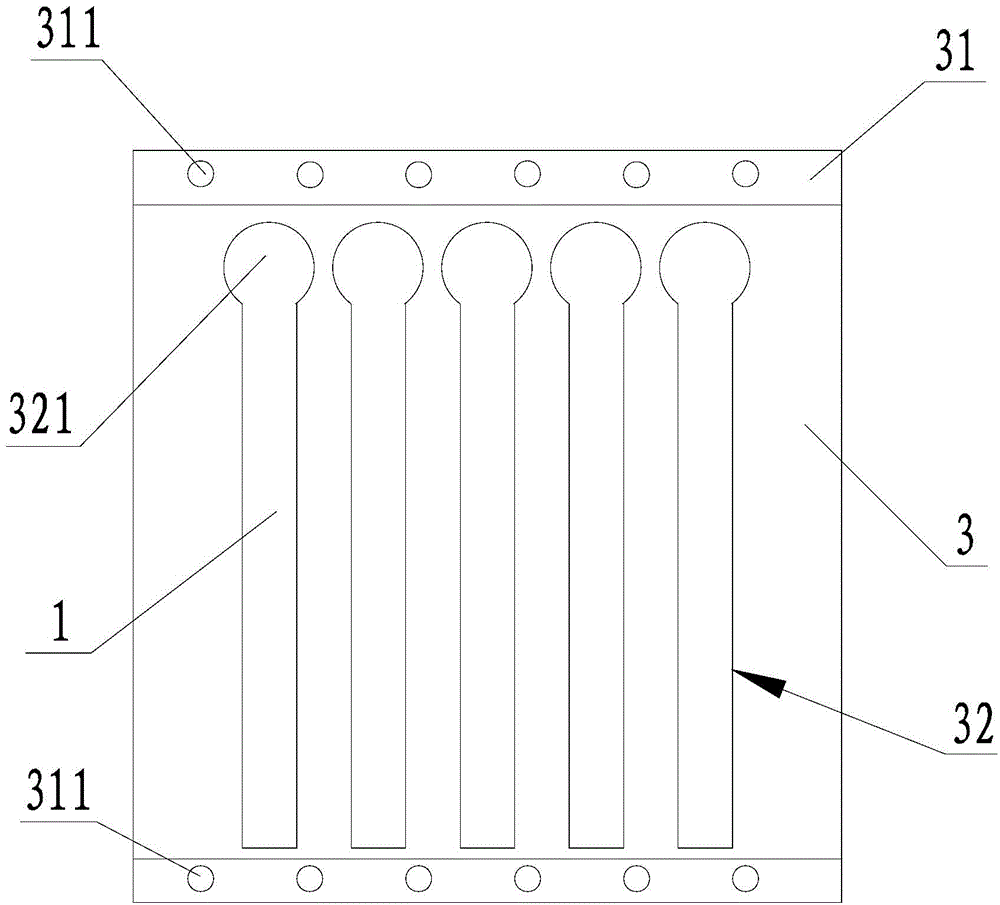

[0025] see figure 1 As shown, the above-mentioned conductive cloth tape with double-sided adhesive includes a conductive cloth layer 1, and the conductive cloth layer 1 includes a shielding base layer 11, and metal layers 12 plated on both sides of the shielding base layer 11 by electroplating or other methods. The shielding base layer 11 is made of one of polyester, nylon, and non-woven fabric, and the metal layer 12 includes at least one of copper, aluminum, stainless steel, or nickel.

[0026] The conductive cloth adhesive tape also includes an adhesive layer 2 attached to the surfaces of both sides of the conductive cloth layer 1. In this embodiment, the adhesive layer 2 adopts a polyurethane conductive adhesive layer, and a release adhesive layer is also pasted on the adhesive layer 2. Layer 3, the release layer 3 can be a release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com