AOI detection method and system

An inspection system and post-inspection technology, applied in measuring devices, optical testing for flaws/defects, conveyor objects, etc., can solve problems such as low AOI inspection efficiency, improve AOI inspection efficiency, simplify operation difficulty, and facilitate operation proficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

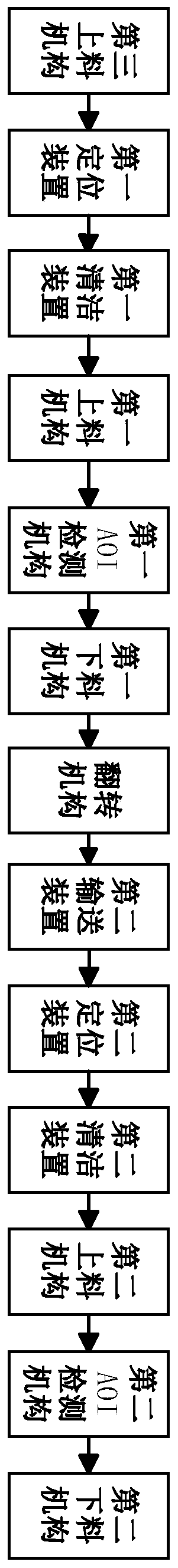

[0040] In this example, refer to figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the AOI detection system; the AOI detection system includes the first feeding mechanism, the first AOI detection mechanism, the first unloading mechanism, the turning mechanism, the second feeding mechanism, and the second AOI Detection mechanism and second feeding mechanism;

[0041] The first positioning device is used to fix the circuit board (such as PCB printed circuit board, etc.) to the first preset position;

[0042] The first feeding mechanism is used to transport the circuit board from the first preset position to the detection position of the first AOI detection mechanism; since the AOI detection mechanism generally uses a camera to obtain the image of the circuit board, and performs subsequent detection according to the acquired image Therefore, the position where the camera can capture the circuit board in the AOI detection mechanism can be used as the d...

Embodiment 2

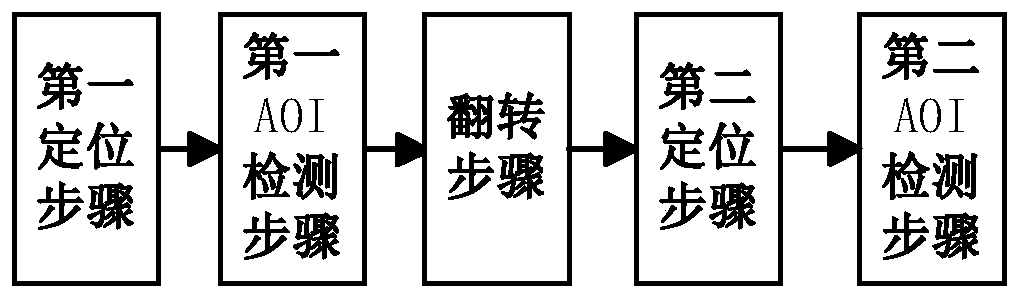

[0067] Provide embodiment 2 based on embodiment 1, embodiment 2 provides a kind of AOI detection method, refer to figure 2 , figure 2 It is a schematic flow chart of an embodiment of the AOI detection method; including the following steps performed in sequence:

[0068] The first positioning step: fixing the circuit board to the first preset position to realize the positioning of the circuit board, and the first positioning device can be used to complete the first positioning step;

[0069] The first AOI detection step: perform the first AOI detection on one side of the positioned circuit board, and use the first AOI detection mechanism to complete the first AOI detection step;

[0070] Flipping step: Flip the circuit board after the first AOI inspection to the other side of the circuit board, and the flipping mechanism can be used to realize the flipping step;

[0071] The second positioning step: fixing the flipped circuit board to the second preset position to position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com