3D printing machine with multiple printing heads

A 3D printer and print head technology, applied in the field of 3D manufacturing, to achieve the effect of shortening the time of material change, continuous adjustment, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

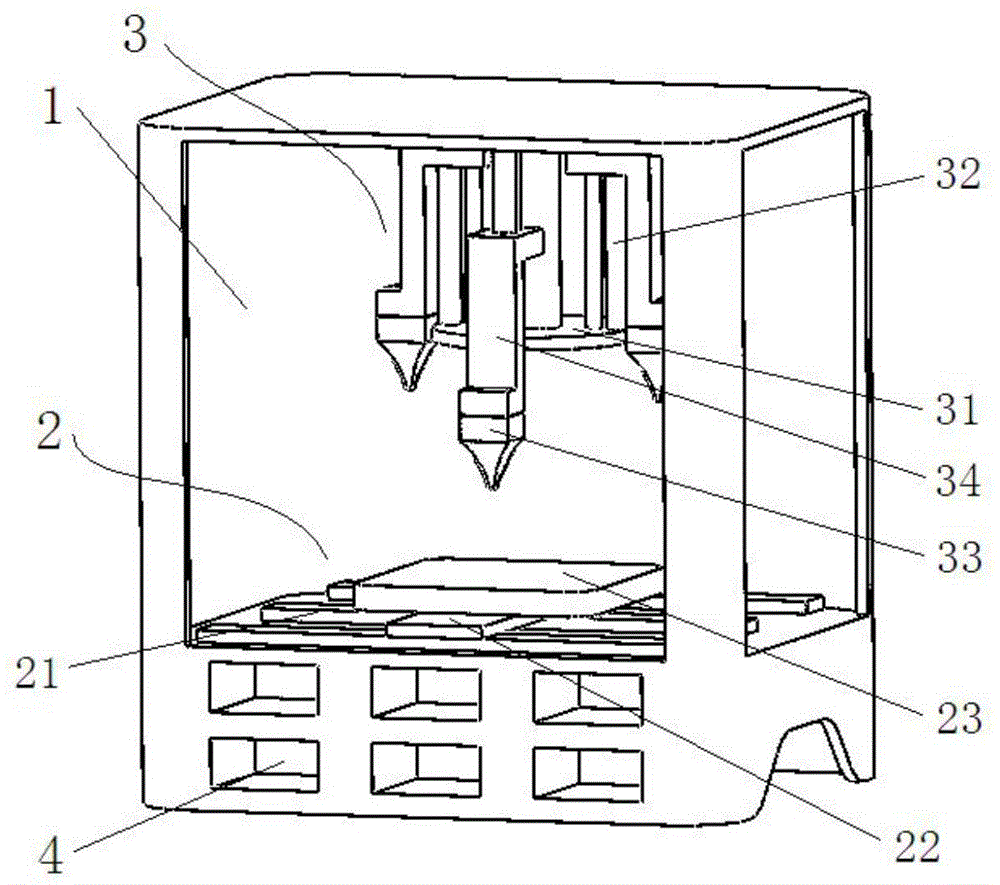

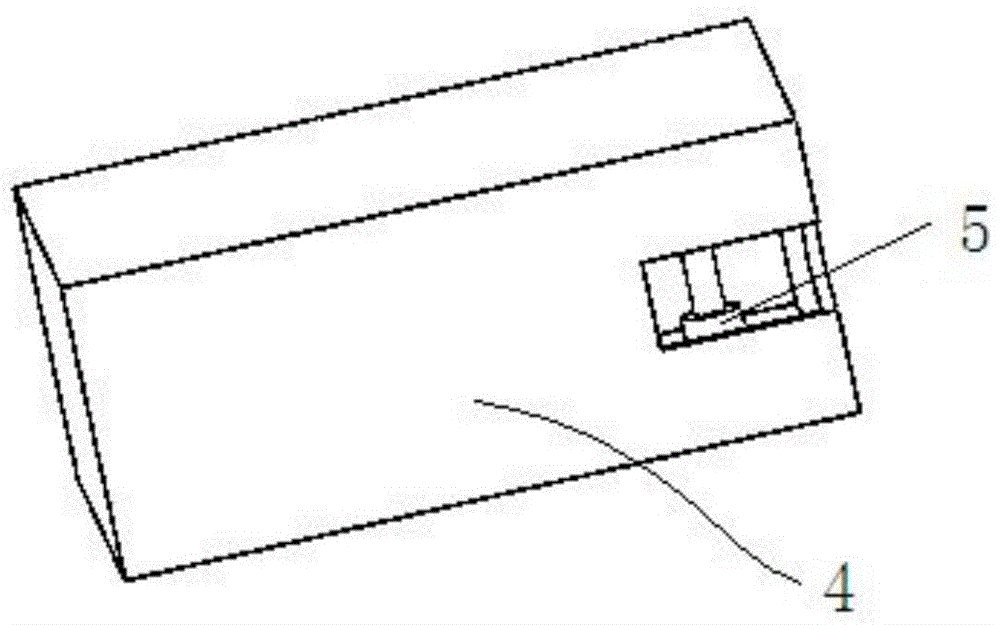

[0015] As shown in the figure, the 3D printer with multiple print heads according to the present invention is characterized in that it includes a frame 1, a mobile workbench 2 for placing workpieces, a print head mechanism 3 for printing workpieces, and several print heads. The head mechanism 3 provides a material box 4 for printing materials and a control system for controlling each component. The mobile workbench 2 and the print head mechanism 3 are correspondingly arranged in the frame 1; the print head mechanism 3 includes a Disc base body 31 and several lift adjustment mechanisms 32 evenly distributed on the disc base body 31, the print head 33 is set on the lift adjustment mechanism 32, and the disc base body 31 is driven to rotate by a motor; The print heads 33 and the material cartridges 4 are provided in one-to-one correspondence. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com