Two-section molding machine of passenger radial tire and molding method thereof

A molding machine and radial tire technology, applied in the field of rubber machinery, can solve problems such as affecting the lamination efficiency and time imbalance, and achieve the effects of improving work efficiency, improving lamination efficiency, and optimizing and balancing working hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

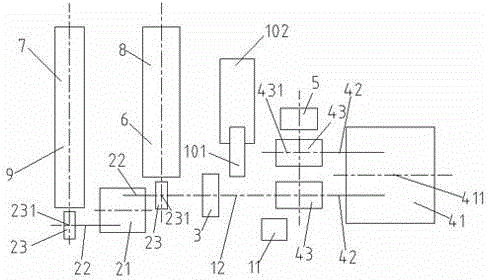

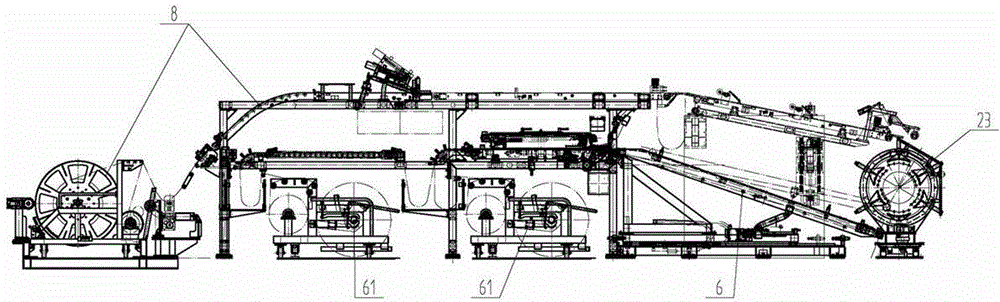

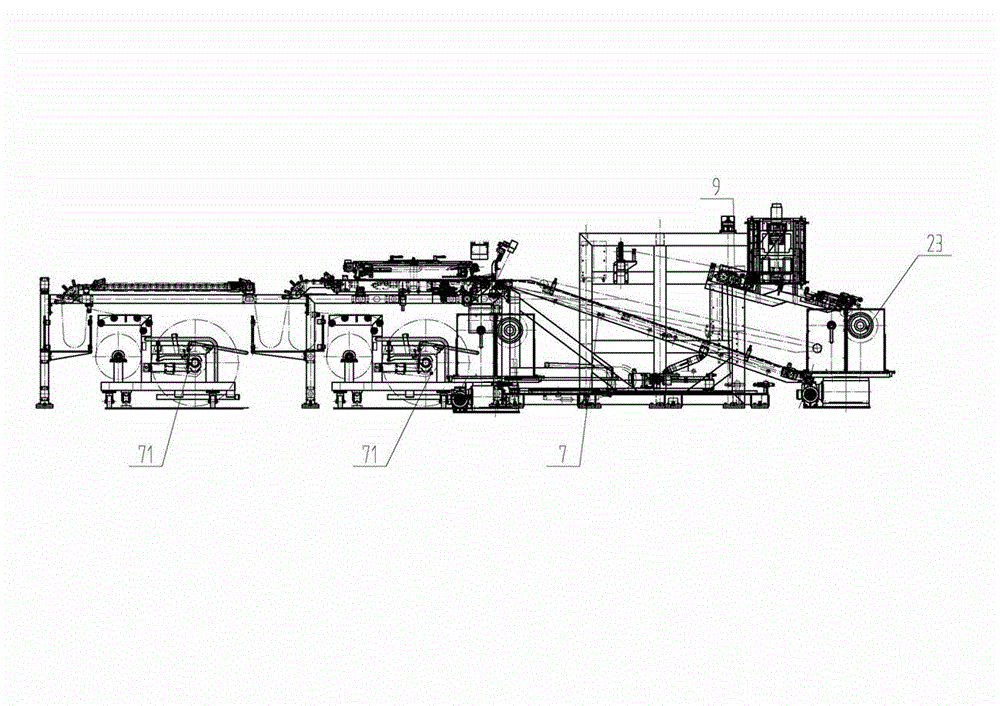

[0043] Example 1, such as figure 1 , figure 2 As shown, the passenger radial tire two-stage building machine of the present invention includes a main machine and a feeding rack, wherein the main machine has a base (1), and a laminating device (2) is sequentially arranged along the base (1) from left to right , the transfer ring (3), the sizing device (4), the transfer ring (3) can realize the transfer of the belt tread assembly by sliding on the slide rail of the base (1).

[0044] The bonding device (2) includes a bonding machine (21), and two sets of belt layers that can be rotated 180 degrees in a horizontal plane around the center line (211) are installed symmetrically along the center line (211) on the bonding machine (21). Drum mechanism, a belt layer drum (23) is installed on the output shaft (22) of each belt layer drum mechanism, and the belt layer drum (23) is distributed on the left and right sides of the laminating machine (21), passing through the Do 180-degree...

Embodiment 2

[0065] Example 2, such as Figure 5 Shown, two sizing drums (43) of sizing device (4) are distributed in the left and right sides of main frame (41), realize mutually alternate station by doing 180 degree of revolutions in horizontal plane.

[0066]

Embodiment 3

[0067] Example 3, such as Figure 6 As shown, the two belt drums (23) of the laminating device (2) are distributed on the left and right sides of the laminating machine (21), and alternate stations are realized by doing 180-degree rotation in the vertical plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com