Novel high-efficient car radial tire molding device

A molding equipment and high-efficiency technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of energy consumption, high labor intensity of workers, and low production efficiency, so as to ensure winding tension, save refueling time, and improve Effect of tread building efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

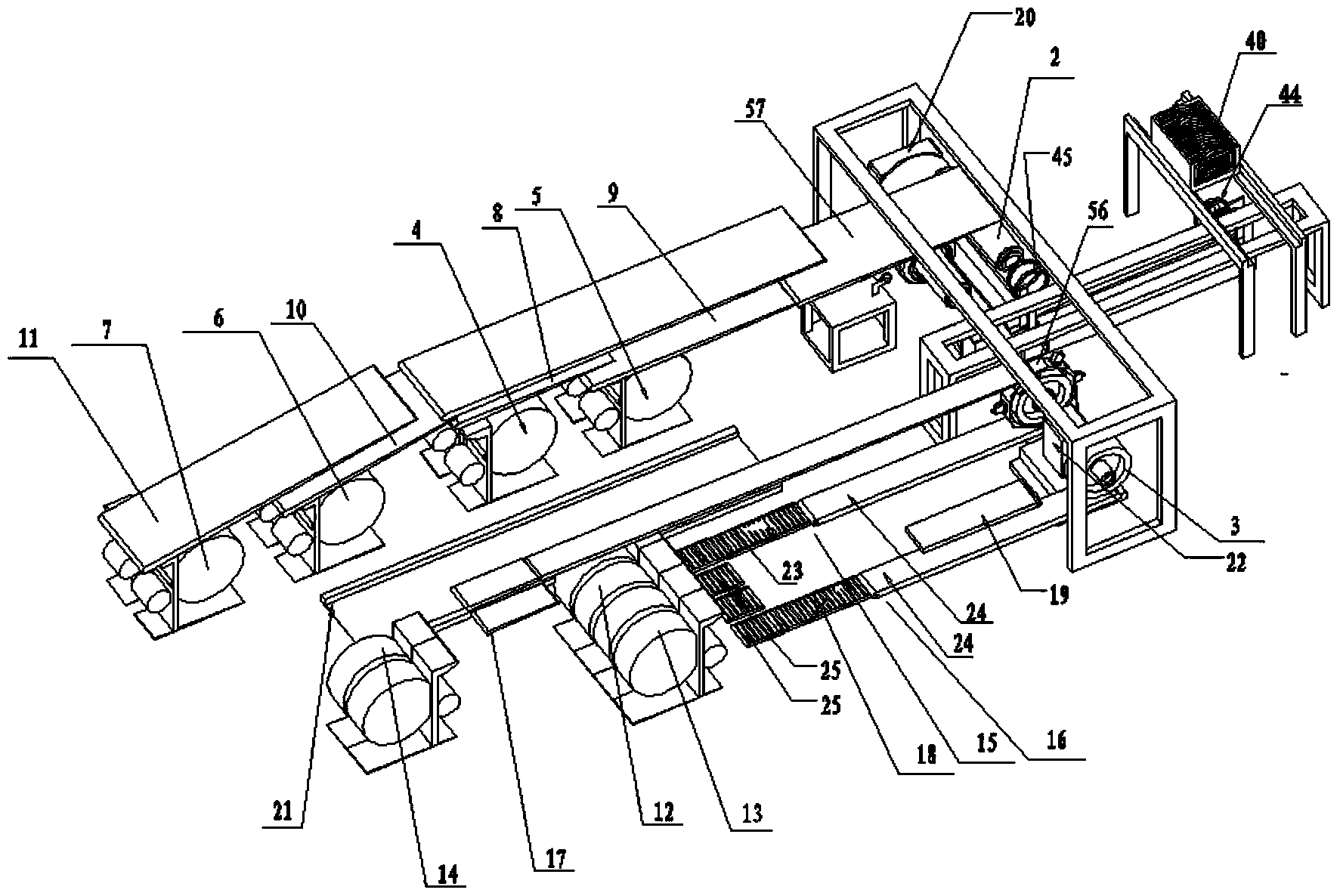

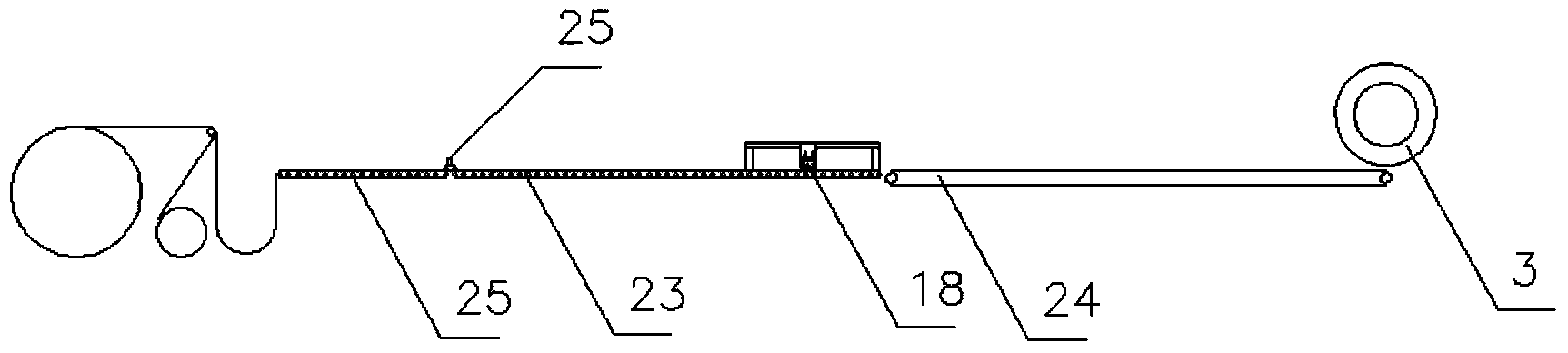

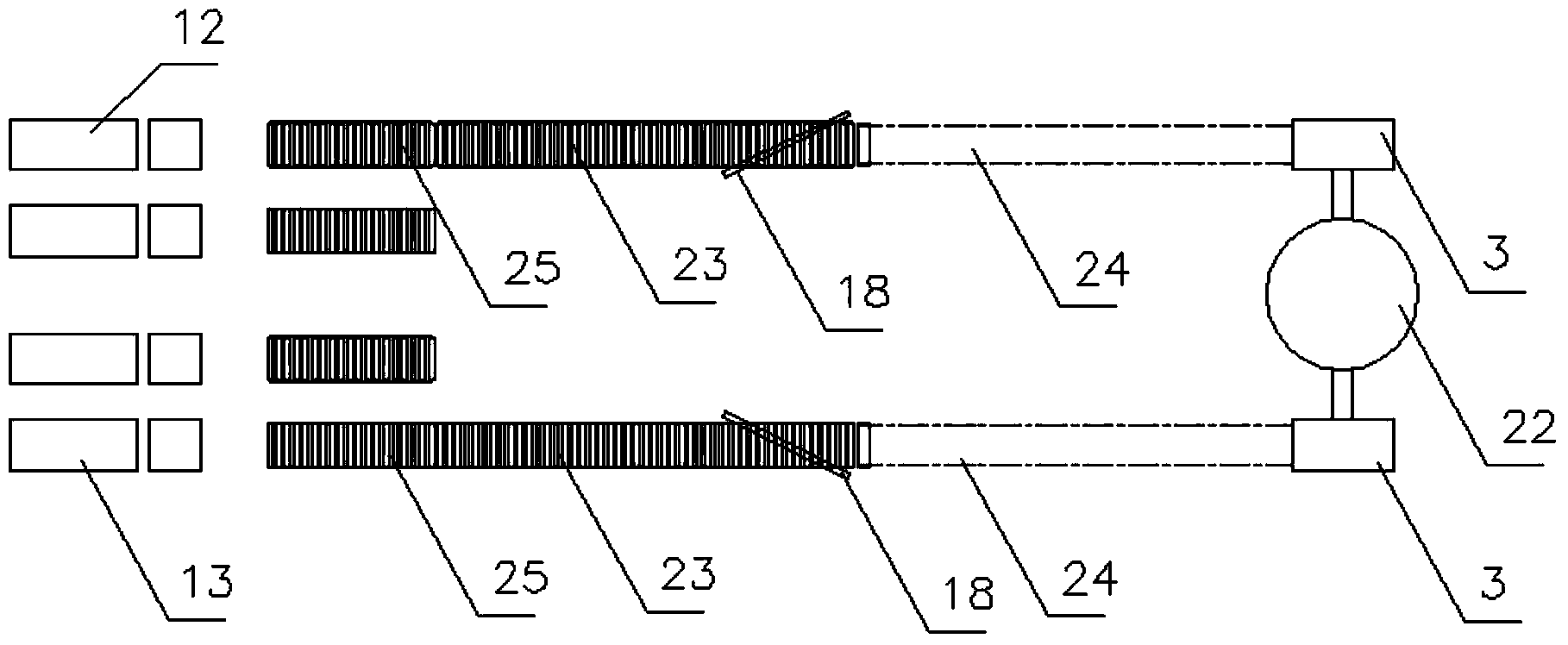

[0046] Embodiment: A new type of high-efficiency passenger car radial tire building equipment, including a base, a carcass drum 2, a belt drum 3, an inner lining feeding car 4, a sidewall feeding car 5, a first layer cord feeding car 6, The second layer of cord feeding car 7, the inner lining conveyor belt 8, the composite conveyor belt 9, the first layer of cord conveyor belt 10, the second layer of cord conveyor belt 11, the steel ring clamping device, the first belt feeding car 12. The second belt feeding vehicle 13, the tread feeding vehicle 14, the first belt conveyor belt 15, the second belt conveyor belt 16, the tread conveyor belt 17, the belt layer cutting device 18, the cap strip The winding equipment 19, the tread transfer ring 56 and the common template 57, wherein the base is respectively provided with a high-precision rotary table 20 and a double-station rotary table 22, and the carcass drum 2 and the belt drum 3 can be rotated and fixedly installed on the On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com