Dual-worktable position interchanging mechanism and leather cutting machine tool containing dual-worktable position interchanging mechanism

A double-table, cutting machine technology, applied in leather punching/punching/cutting, small raw hides/large raw hides/leather/fur mechanical processing, small raw hides/large raw hides/leather/fur processing, etc. Occupy the working time, the worktable does not have the interchange function, the production efficiency is low, etc., to achieve the effect of saving the material change time, high cost performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

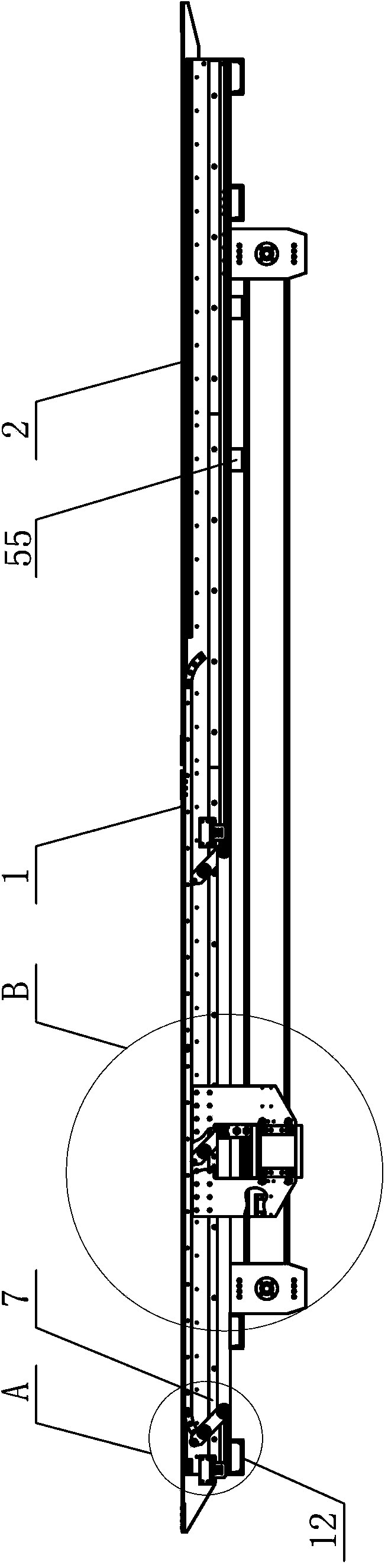

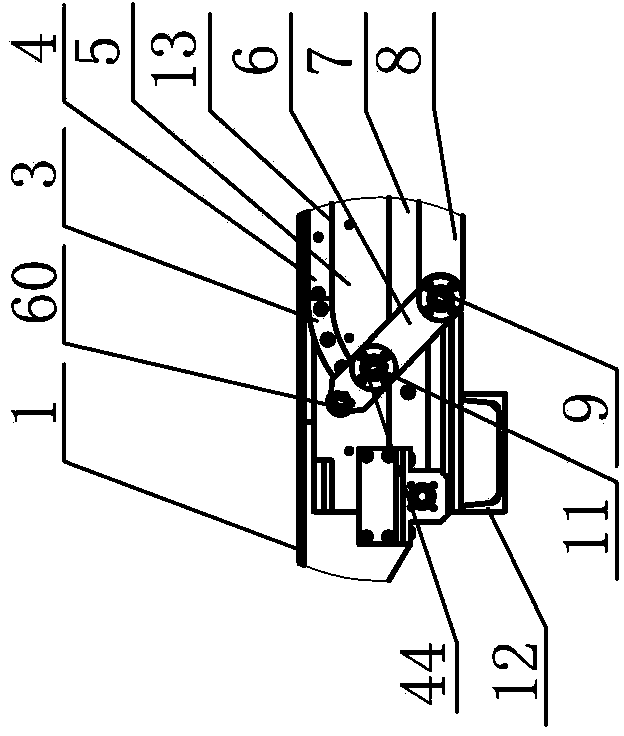

[0027] Specific implementation mode one: combine Figure 1 to Figure 6 Explain, the double workbench position exchange mechanism 101 of this embodiment, the double workbench position exchange mechanism 101 includes the lifting platform 1, the translation platform 2, the base 12, the lifting platform telescopic plate mechanism, the chain transmission mechanism, the belt transmission mechanism , two parallel quadrilateral travel mechanisms of lifting platforms, two guide rails 13, two guide rails 27, two translation platform vertical plates 53, two translation platform guide rails 29, four sets of translation platform travel wheels 42 and two channel steels 1.5; each lifting platform parallelogram walking mechanism includes the lifting platform long connecting rod 8, the lifting platform vertical plate 54, the upper walking wheel 60 of the lifting platform, the lower walking wheel 44 of the lifting platform, three guiding wheels 48 of the lifting platform and three lifting platfo...

specific Embodiment approach 2

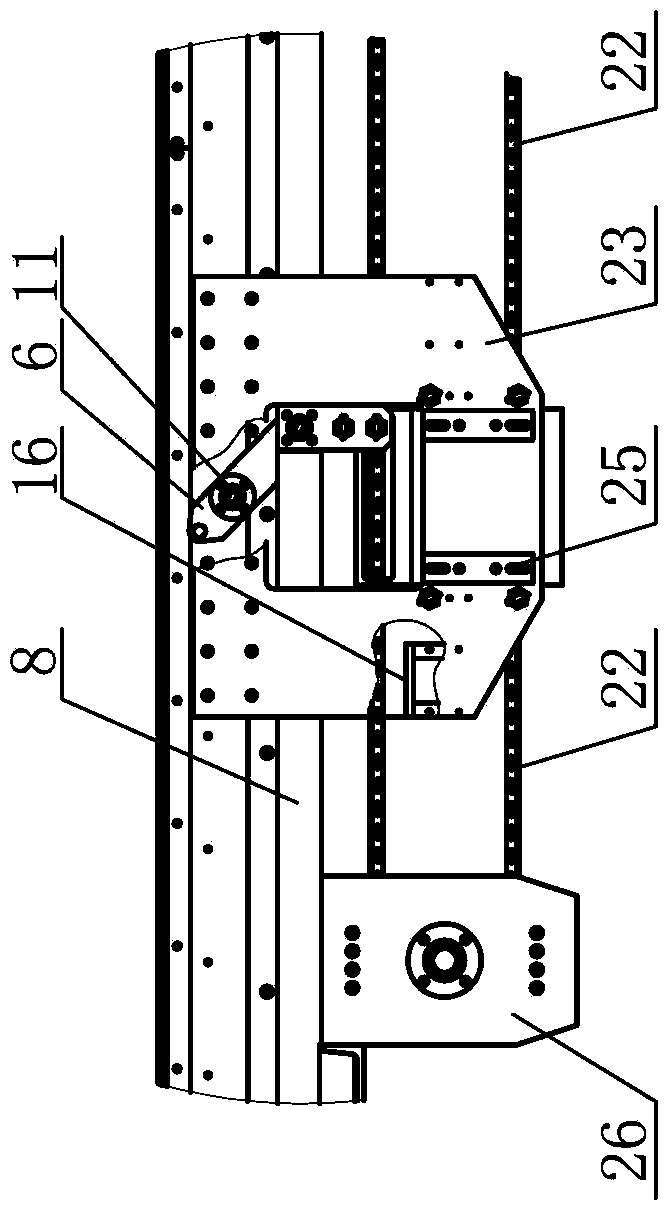

[0035] Specific implementation mode two: combination figure 1 , figure 2 , Figure 5 and Figure 6 Explain that each roller cover mechanism 57 of the present embodiment includes four lifting platform expansion plate side rollers 35, two lifting platform expansion plate pressing wheel seats 39, two lifting platform expansion plate pressing wheel one 38 and four lifting platforms Expansion plate pressure wheel two 25;

[0036] The back of each expansion board seat 23 is located on the left side and right side of the transparent groove, and two lifting platform expansion board side rollers 35 are respectively rotated from top to bottom. The rim of the roller 35 is arranged on the left side of the telescopic plate 36, and the rims of the side rollers 35 of the two lifting platform telescopic plates on the right side of the through groove are arranged on the right side of the telescopic plate 36 to limit the expansion and contraction. The left and right swing of the plate 36; ...

specific Embodiment approach 3

[0038] Specific implementation mode three: combination Figure 5 Explain that the belt drive mechanism in this embodiment includes a large pulley 61, a small pulley 62, a small pulley shaft 63 and a synchronous belt 64; the small pulley 62 is installed on the small pulley shaft 63, and the small pulley shaft 63 is connected to the output Shaft drive connection, the small pulley 62 is connected with the large pulley 61 through a synchronous belt 64. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0039] Specific implementation mode four: combination figure 1 , Figure 7 to Figure 9 Explain, a kind of leather cutting machine tool of this embodiment is equipped with the double workbench position exchange mechanism described in specific embodiment 1, 2 or 3, the leather cutting machine tool includes double workbench position exchange mechanism 101, cutter assembly 102 , photographing and projecting equipment assembly 103, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com