Automatic processing equipment for metal tubes

A technology for processing equipment and metal pipes, which is applied in the field of automatic processing equipment for metal pipes, can solve problems such as low turning production efficiency, achieve the effects of improving production efficiency, realizing automatic loading and unloading production, and ensuring accurate matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

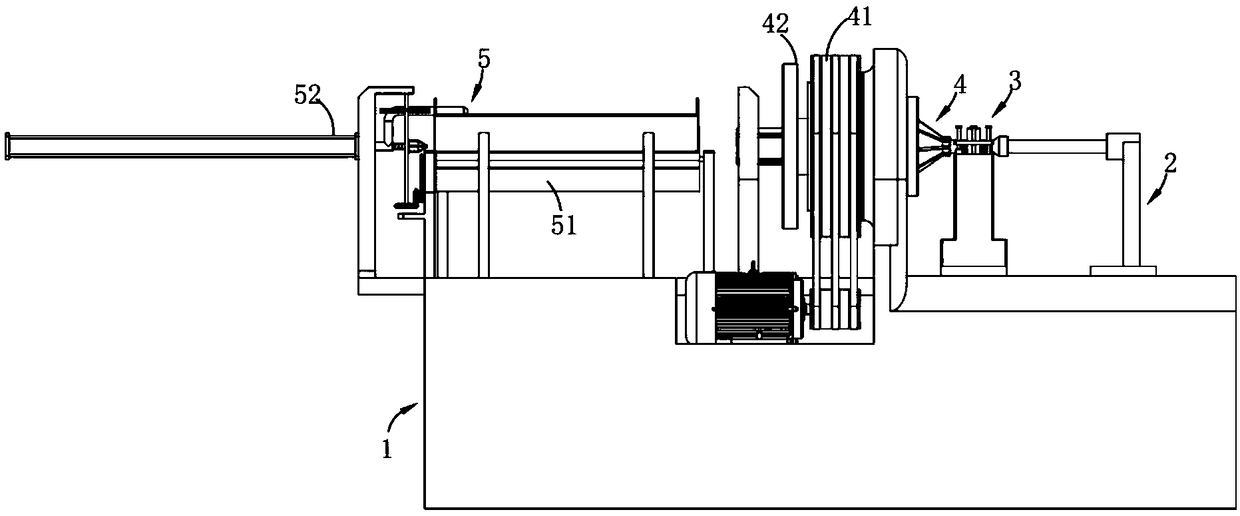

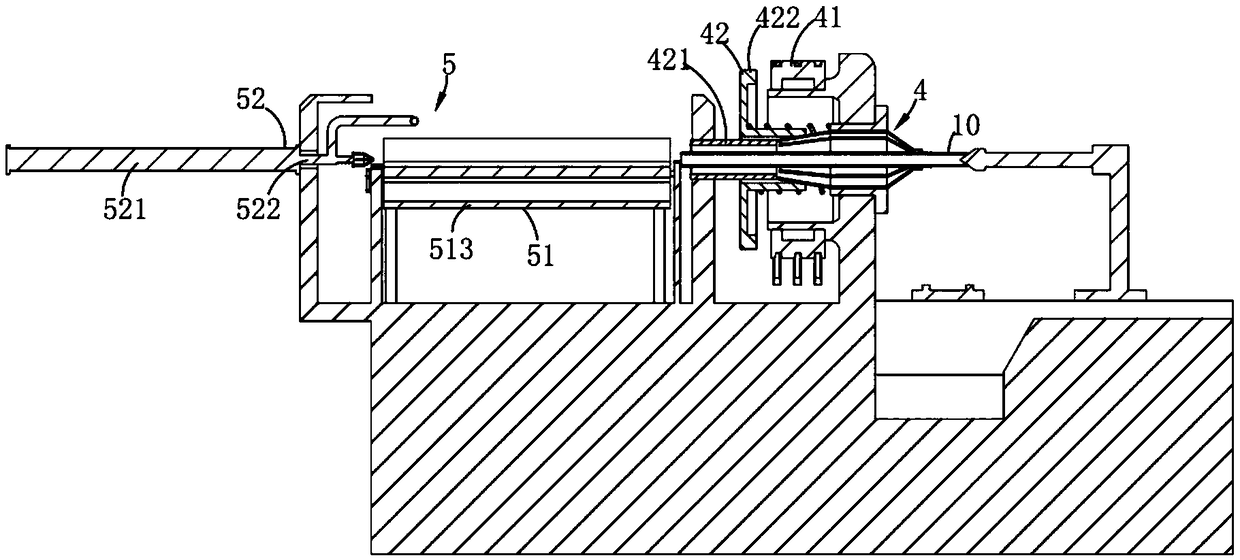

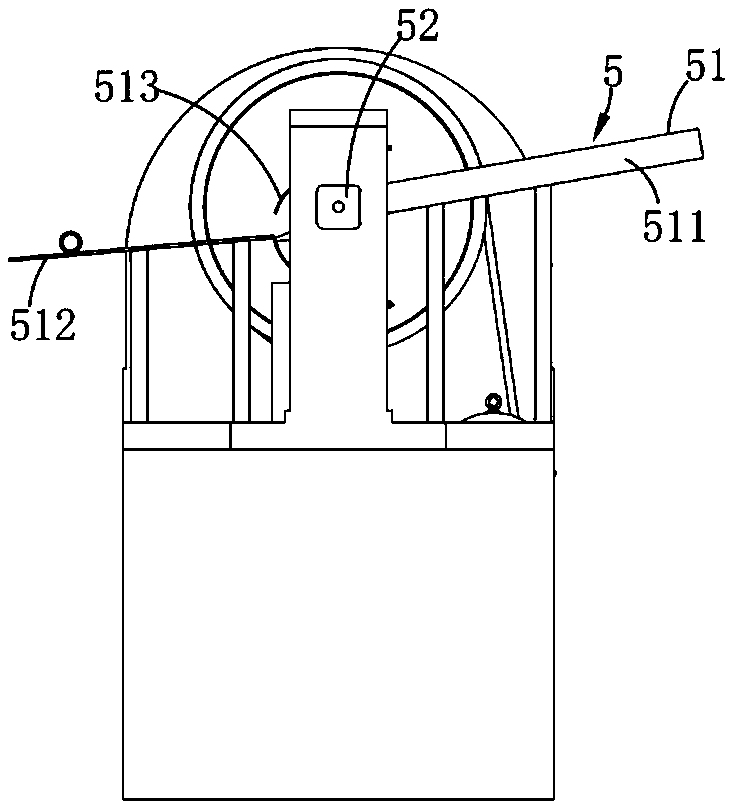

[0037] Such as figure 1 , 2 As shown in , 3, 4 and 5, a metal pipe automatic processing equipment includes a bed 1, a top cone 2 and a turning mechanism 3, and also includes:

[0038] The clamping mechanism 4, the clamping mechanism 4 includes a power assembly 41 arranged on the bed 1 and a clamping assembly 42 that drives the workpiece 10 to rotate, the clamping assembly 42 includes a power assembly 41 arranged in the power assembly 41 and The rotating jacket 421 and the pretensioning part 422 that squeezes the jacket 421 to t...

Embodiment 2

[0044] Such as figure 1 , 2 As shown in and 8, the same or corresponding parts as in the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; The difference is that the push assembly 52 is fixedly arranged on the bed 1 and is located at one end of the transfer assembly 513, which includes a fixed cylinder 521, a reciprocating moving rod 522 driven by the cylinder 521, and a The end of the moving rod 522 is a positioning part 523 for positioning and tightening the workpiece 10 in the transfer assembly 513 , and a clutch fixed on the moving rod 522 to push the connection between the transmission plate 4222 and the power assembly 41 part 524 and the control part 525 that drives the transfer assembly 513 to rotate in the process of moving through the clutch part 524; The clutch part 524 pushes the turntable 4222 into contact with the power assembly 41 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com