Punching device for processing disposable food box mould

A mold processing, one-time technology, applied in metal processing and other directions, can solve the problem of low processing efficiency, achieve the effect of improving processing efficiency, strong practicability, and saving refueling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

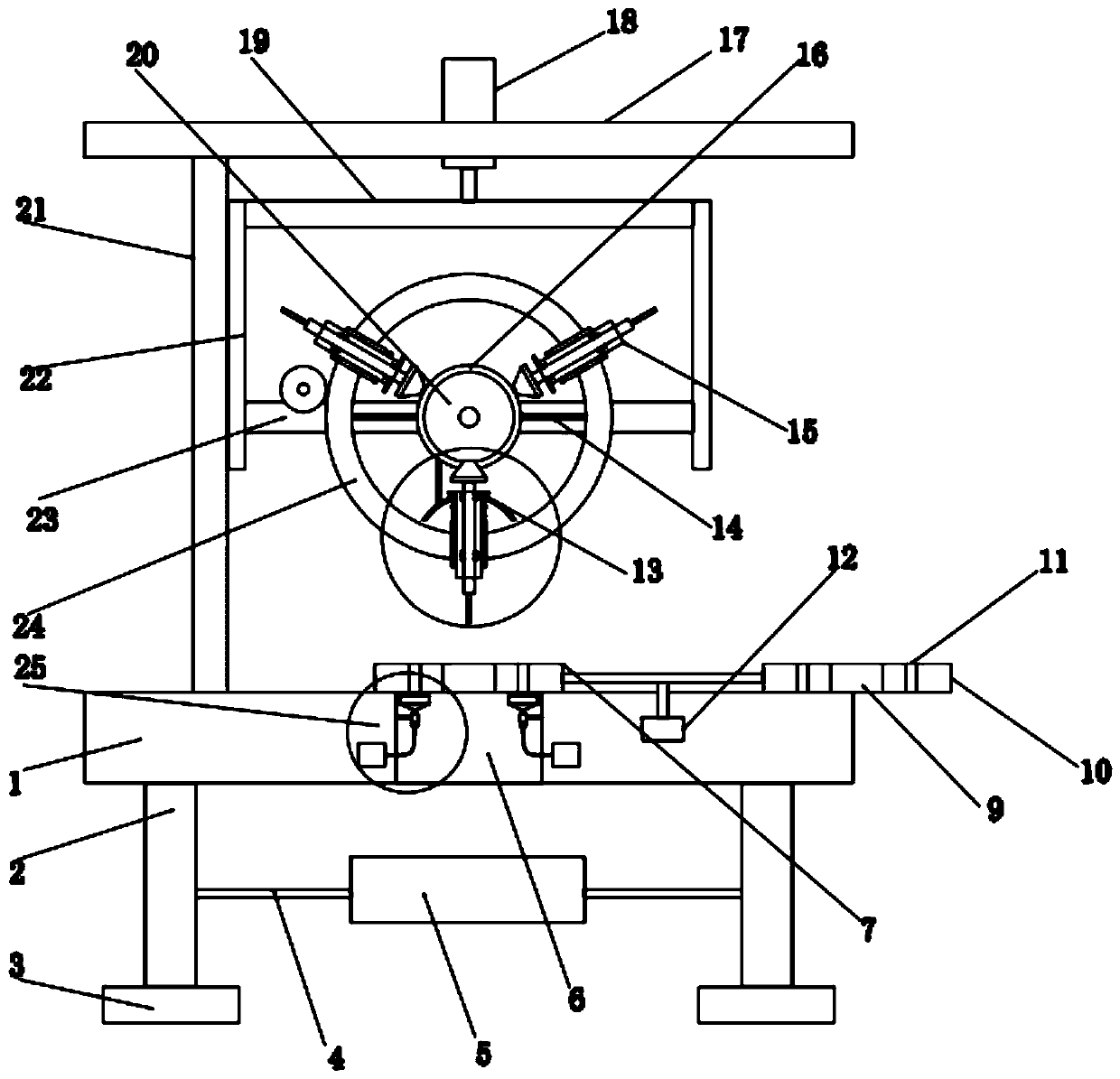

[0038] see Figure 1-4 , in the embodiment of the present invention, a kind of perforating device for mold processing of disposable lunch box, comprises base 1 and support leg 2 that is arranged on both sides of the lower end of base 1, and the lower end of described support leg 2 is provided with support block 3, left and right supports A collection box 5 is arranged between the legs 2, and the two sides of the collection box 5 are connected and fixed with the legs 2 by positioning rods 4;

[0039] The top of the base 1 is provided with a top plate 17, and the lower left side of the top plate 17 is connected and fixed with the base 1 by a support column 21. The base 1 is provided with a lower mold assembly for placing a lunch box to be processed, and the upper end of the top plate 17 is A lifting hydraulic cylinder 18 is installed, and the output end of the lifting hydraulic cylinder 18 is connected to the upper mold assembly corresponding to the lower mold assembly;

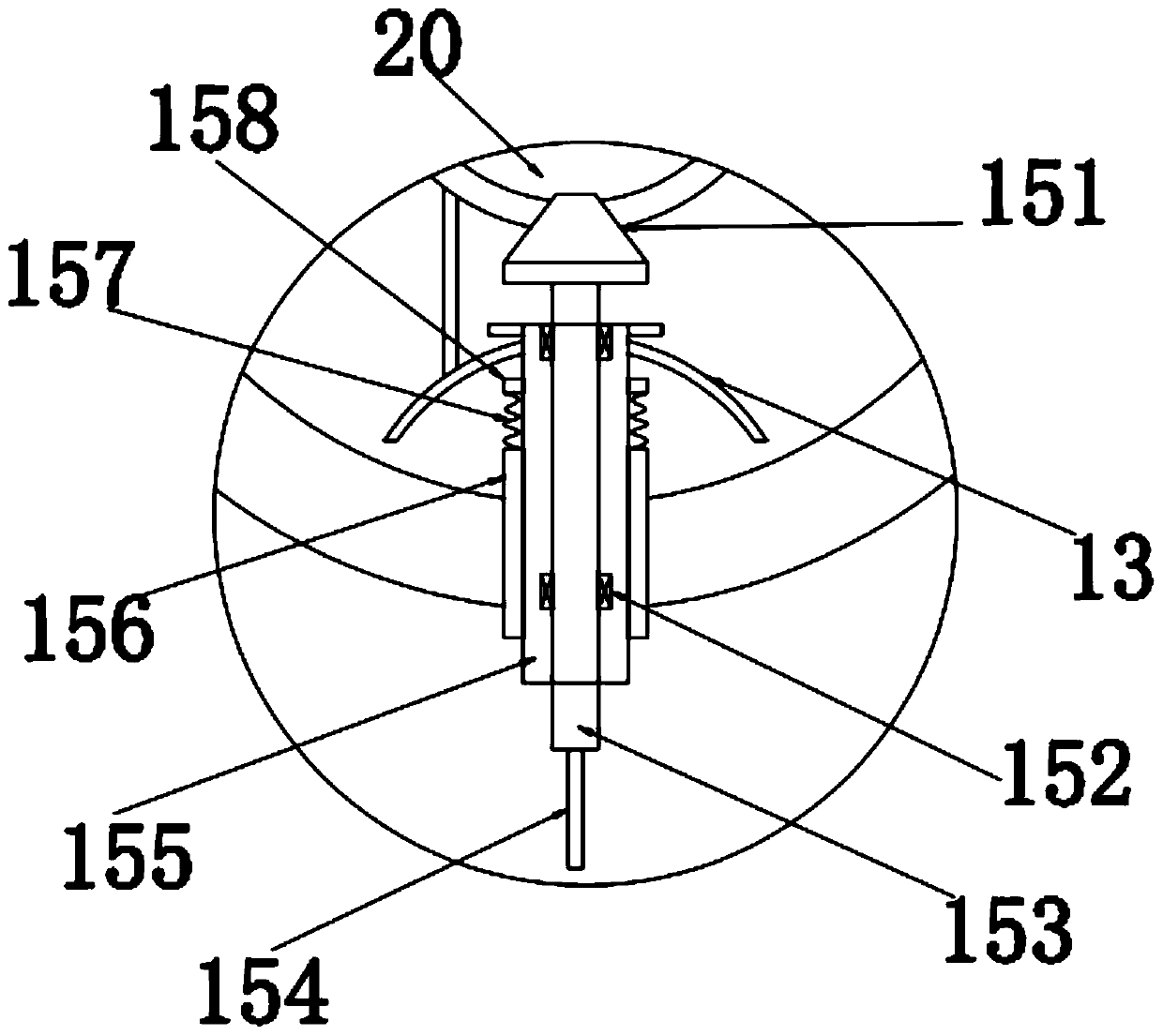

[0040...

Embodiment 2

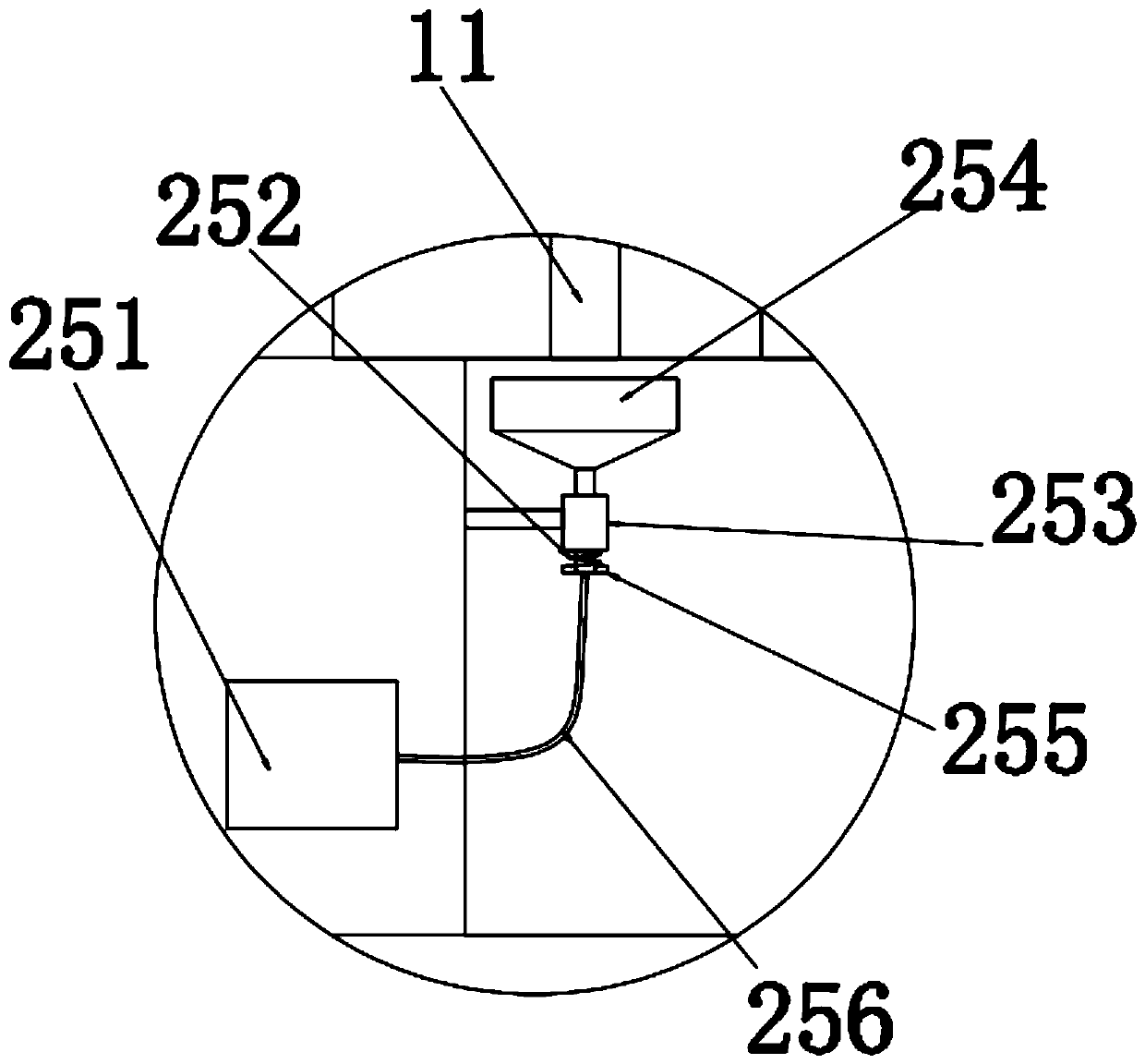

[0053] see image 3 The difference from Embodiment 1 is that the auxiliary fixing assembly 25 includes a negative pressure pump 251 arranged inside the base 1, and the suction end of the negative pressure pump 251 is connected to the fixing tube at the lower end of the suction cup 254 through a suction tube 256, so The sliding sleeve on the fixed pipe is provided with a sliding sleeve 253, and the sliding sleeve 253 is connected and fixed with the inner wall of the blanking opening 6 through a positioning rod. Connect and fix by telescopic spring 252;

[0054] The first lower module 7 and the second lower module 10 are provided with adsorption holes 11 corresponding to the suction cups 254;

[0055] During post-processing, when the lower module rotates to the blanking port 6, under the action of the negative pressure pump 251, the upper end of the suction cup 254 will generate an adsorption force, and under the action of the adsorption force, the suction cup 154 will contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com