Synchronous control system for longitudinal beam hydraulic machine

A technology of synchronous control and hydraulic press, which is applied in the field of hydraulic press, can solve the problems of heavy slider weight, many consumables, and tilting moment of hydraulic press beam, and achieve the effect of improving the overall coordination, ensuring safe work, and reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

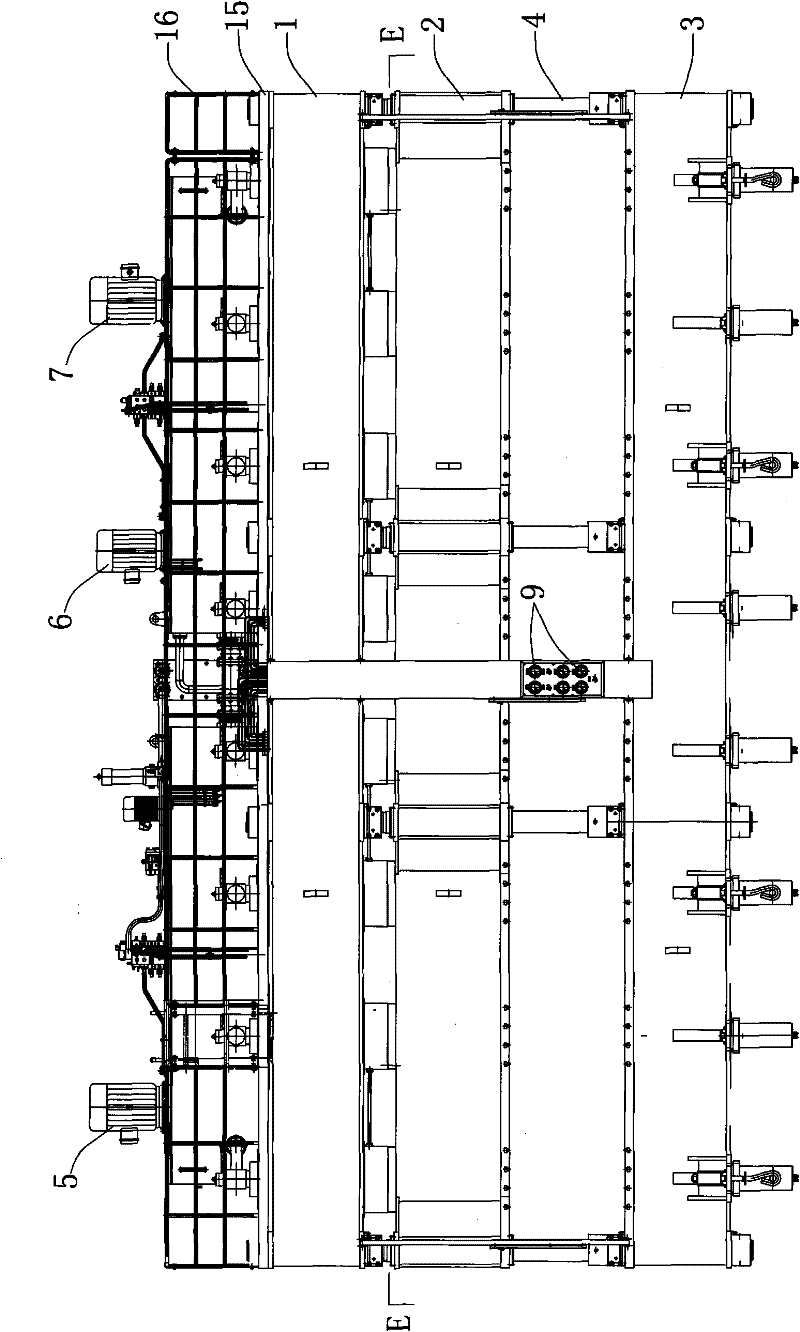

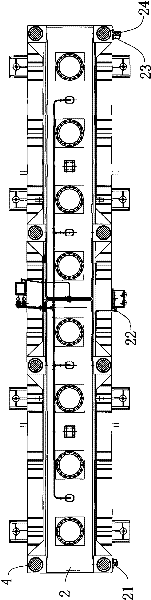

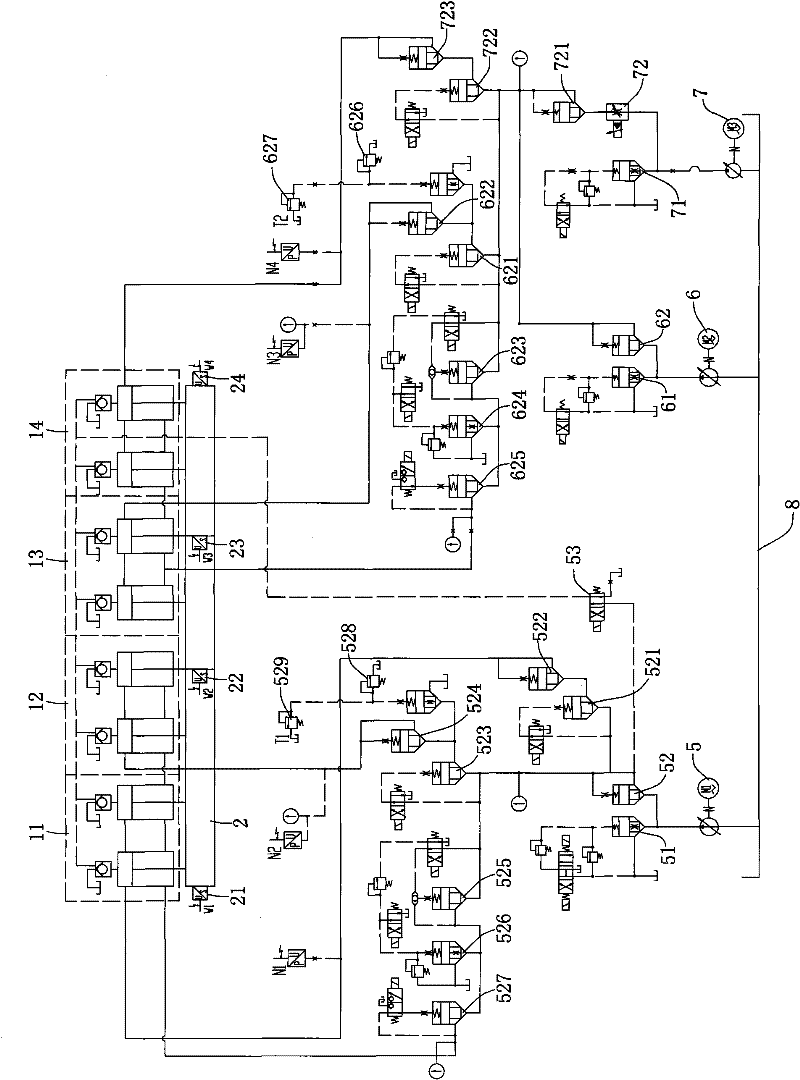

[0020] Such as Figure 1 to Figure 3 As shown, the present invention provides a synchronous control system for a longitudinal beam hydraulic machine, which includes a hydraulic machine body, a beam, a workbench, and a slider that is slidably installed between the beam and the workbench through several sets of guide rail mechanisms. A main oil cylinder connected to the lower slider, and a power mechanism is arranged above the beam, and the power mechanism includes a variable oil pump motor unit that controls the normal pressure power of the main oil cylinder and a proportional servo oil pump motor unit that controls the compensation power of the main oil cylinder. It is a flexible beam, and the variable oil pump motor unit selects one or more sets of corresponding main oil cylinders to control according to the workpiece pressing length and pressing position; the fuselage is equipped with the displacement information of multiple positions of the induction slider relative to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com