A fin assembly equipment for radiator shells for 5G base stations

A technology for assembling equipment and heat sinks, which is applied in the field of communication, can solve the problems of poor heat dissipation, long cooling time, and poor heat dissipation of the shell, so as to ensure structural strength and heat dissipation effect, improve processing efficiency, and reduce cooling volume. The effect of shrinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the techniques, creative features, objective and efficacy of the present invention, and the embodiments are further illustrated in connection with the specific embodiments.

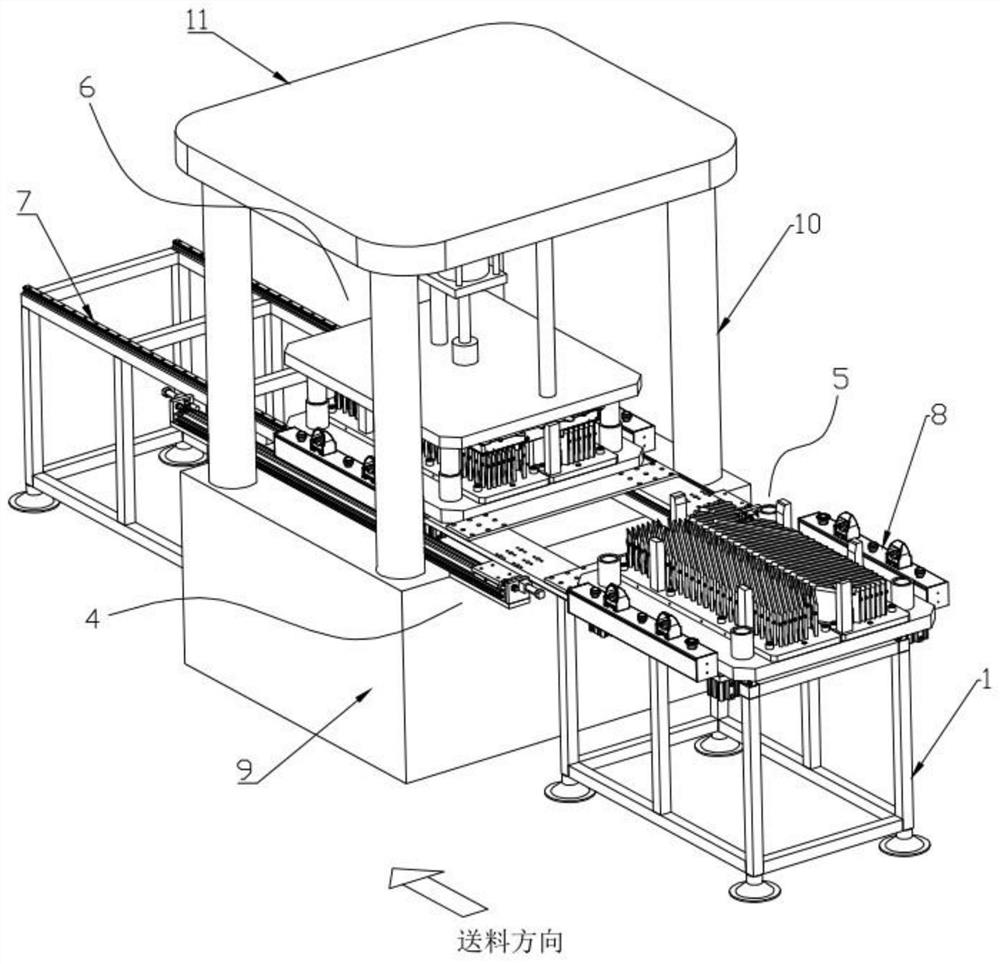

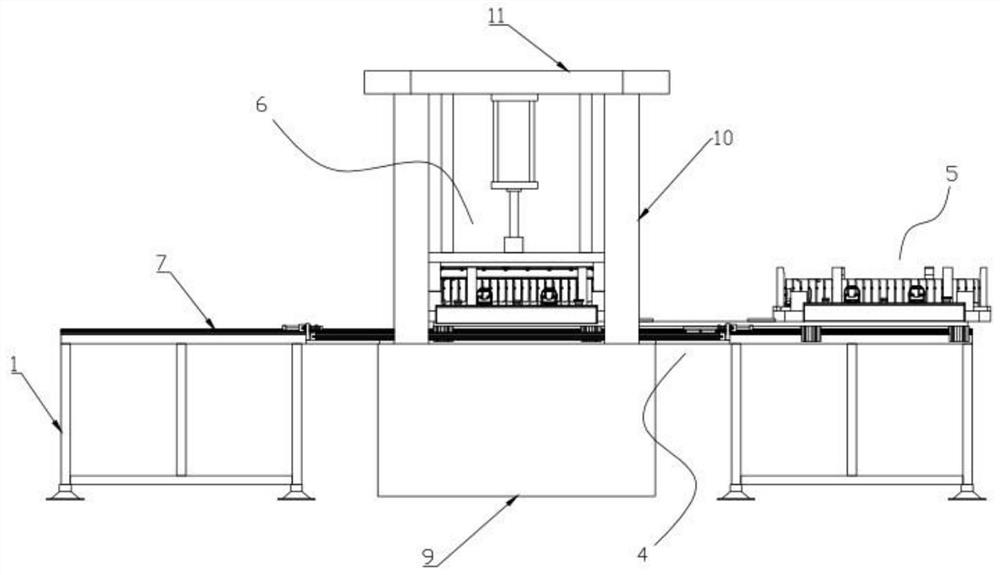

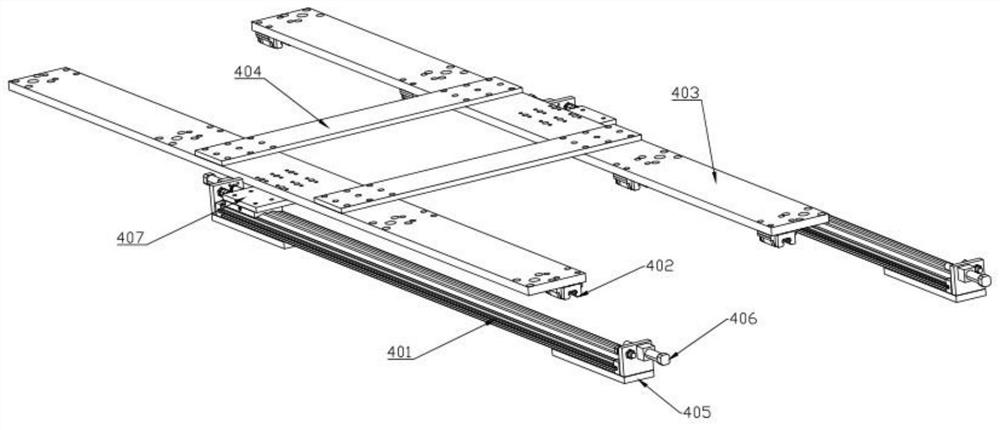

[0026] like Figure 1 to 8 As shown in A 5G base station apparatus fitted with a pair of wings radiator housing, comprising a frame 1, a base 2, a pair of wings 3, the conveying mechanism 4, the mounting mechanism 5 and a stopper mechanism 6, the upper end of the frame 1 in the feed direction is attached to two symmetrically arranged rails 7, the conveying mechanism 4 slidably mounted on the rail 7, and the finished product for feeding and discharging process, the mounting mechanism 5 is mounted to the transport mechanism 4, the upper end, and for mounting the base body 2 and a pair of wings 3, 4 is an end side of the transport mechanism to the mounting mechanism 5 is attached to a position corresponding to the controller 8, the lower end of the frame 1 is fixed to the casing 9, the sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com