Scraping structure of deformable plank combination machine using superimposed magnetic positioning

A technology of machine scraping and magnetic positioning, which is applied in the direction of wood processing equipment, manufacturing tools, adhesive application devices, etc., can solve the problems of time-consuming, easy-to-scratch wood board surface, overflowing glue, etc., and achieve the effect of improving the leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

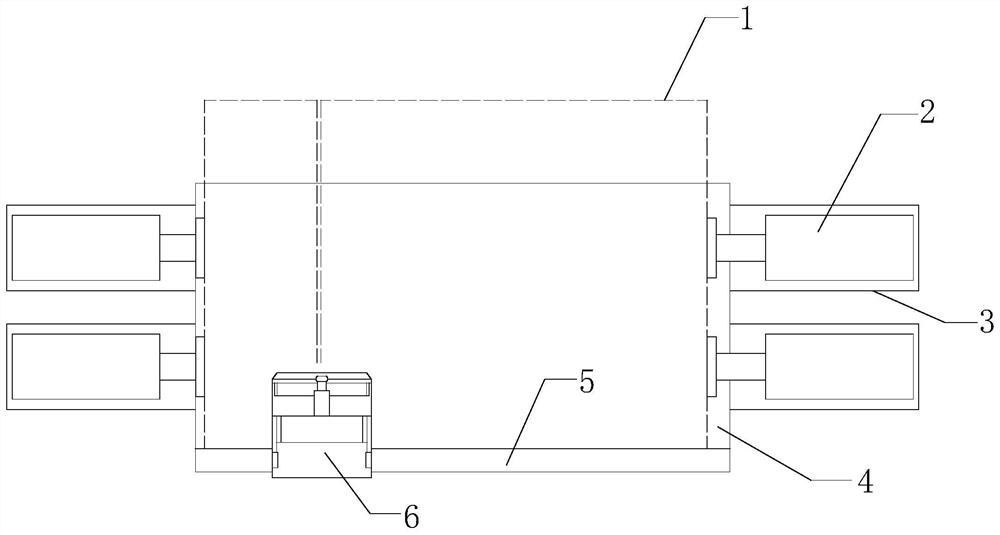

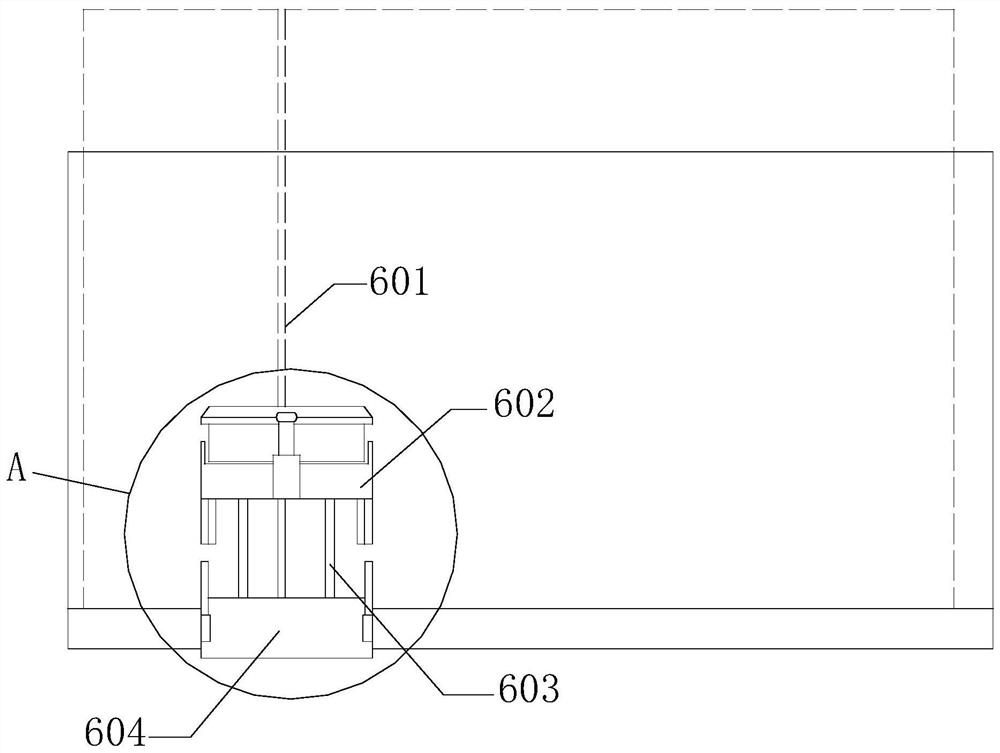

[0029] see Figure 1-Figure 6 , the present invention provides a scraper structure for a deformable plank combination machine that adopts magnetic stacking positioning. one, and respectively installed on the surface of the mounting plate 3, the mounting plate 3 is provided with four, and respectively installed on the left and right sides of the platform 4, the front end of the platform 4 is provided with a main rail 5, and is an integrated structure, the The workpiece 1 is arranged on the surface of the platform 4, and both sides are connected with the cylinder 2, the scraper 6 is fastened with the main rail 5, and the mounting plate 3 is used to fix the cylinder 2 on both sides of the platform 4. The plank is placed on the platform 4, and then the two planks are pushed by the cylinder 2 to be combined and close together.

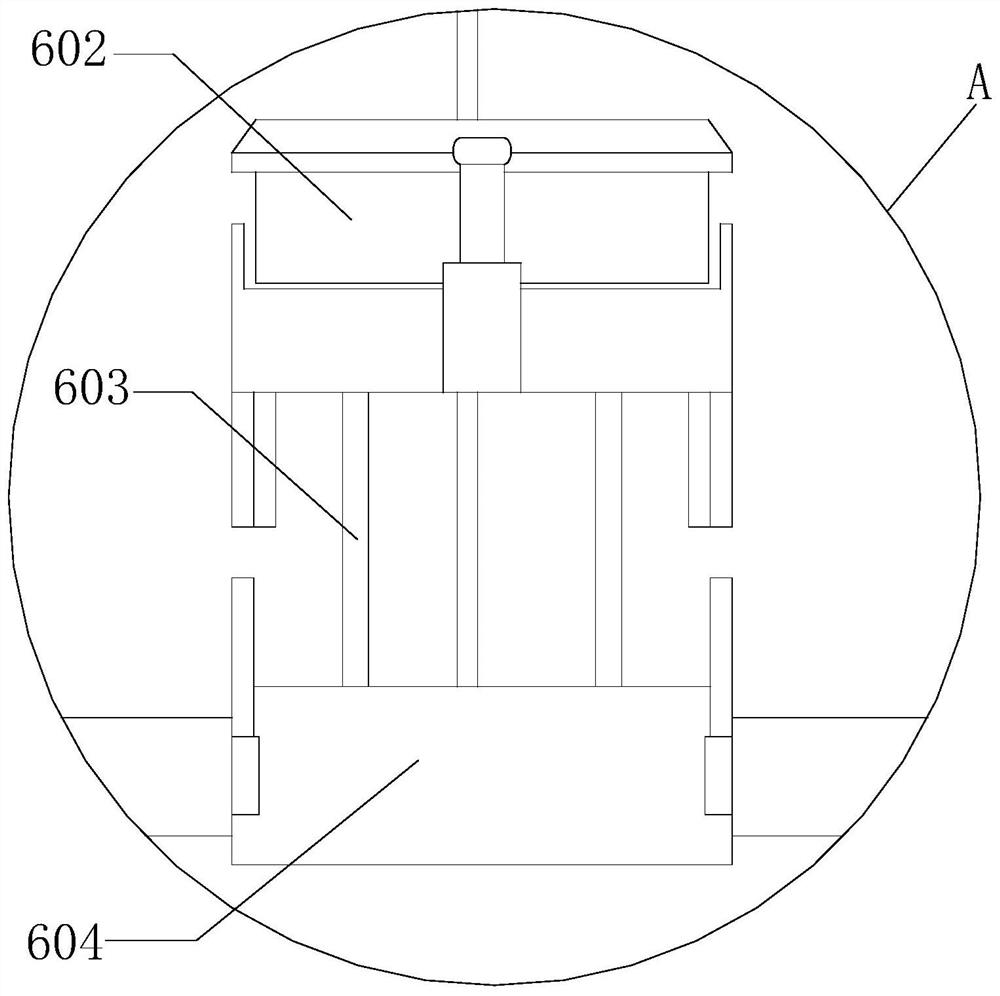

[0030] The scraper 6 includes a combination line 601, a parallel scraper frame 602, a return bar 603, and a translator 604. The translator 604 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com