Riveting machine for eyelets of hand bag

A riveting machine and handbag technology, applied in bag making, container manufacturing machinery, paper/cardboard containers, etc., can solve problems affecting the fastening degree of corns, achieve the effect of tight riveting and reduce gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

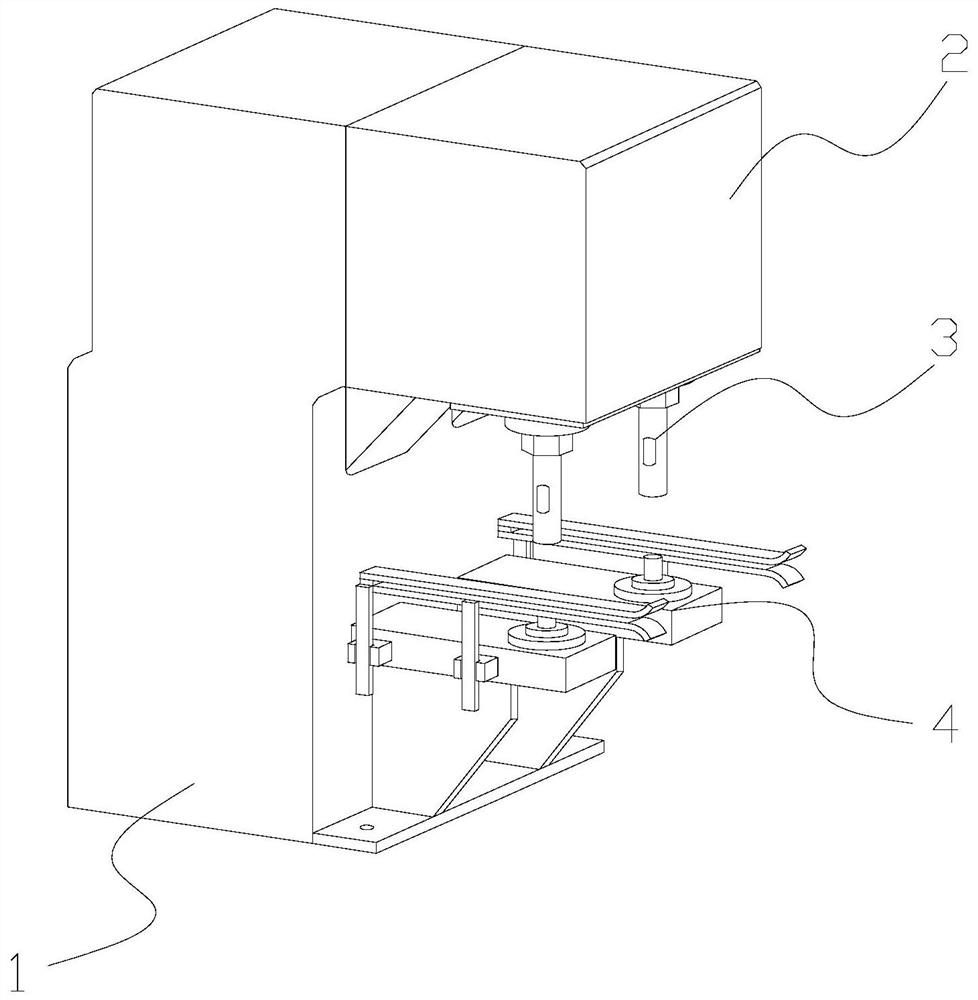

[0029] Example 1: Please refer to Figure 1-Figure 4 , the specific embodiments of the present invention are as follows:

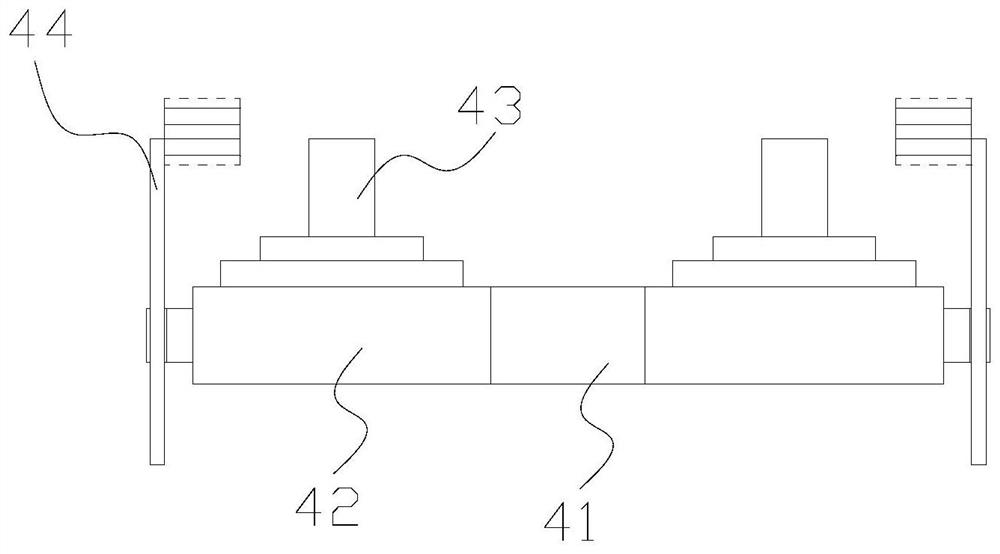

[0030] Its structure includes a chassis 1, a drive box 2, a push rod 3, and a workbench 4. The drive box 2 is horizontally installed above the front end of the chassis 1 and is mechanically connected. The push rod 3 is embedded in the drive box 2 and is movable connection, the workbench 4 is set at the front end of the chassis 1 and is located below the push rod 3; the workbench 4 includes a connecting frame 41, a base 42, a placement table 43, and a guide structure 44, and the base 42 is horizontally installed on the connecting frame 41 Between and welded, the placement table 43 is vertically installed on the upper end of the base 42 and is mechanically connected, and the guide structure 44 is arranged on both sides of the base 42 and is fixedly connected.

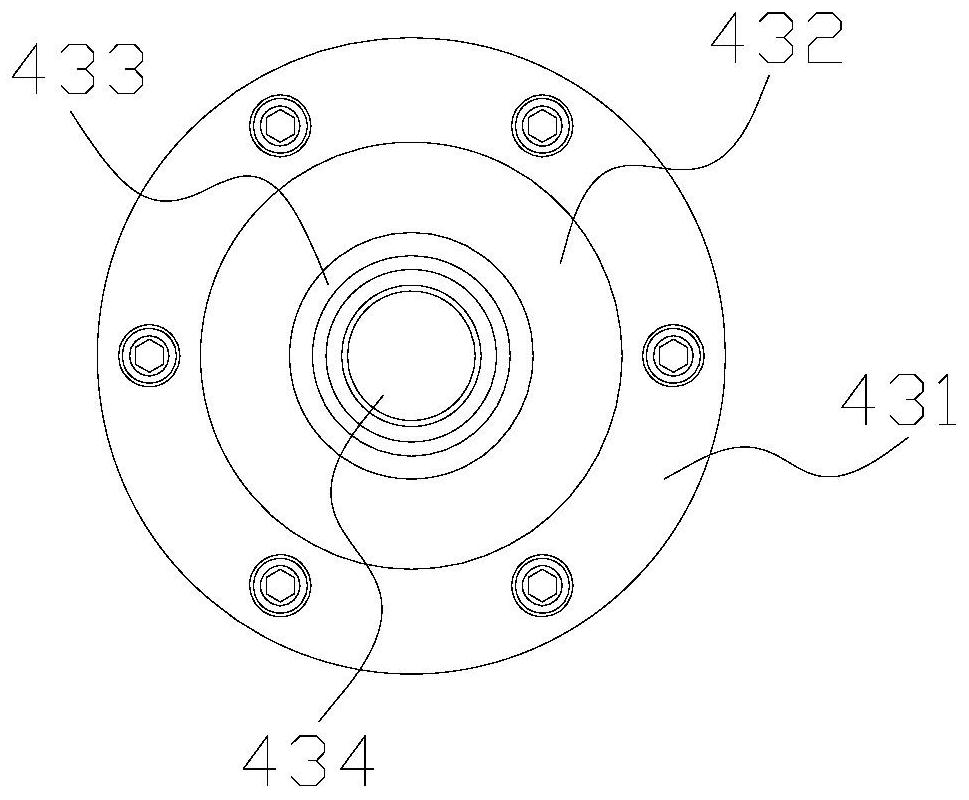

[0031] refer to image 3 , the placement table 43 includes a mounting plate 431, an inner plate ...

Embodiment 2

[0035] Example 2: Please refer to Figure 5-Figure 9 , the specific embodiments of the present invention are as follows:

[0036] The guide structure 44 includes a guide block 441, an adjustment plate 442, a clamping plate 443, and a restriction structure 444. The adjustment plate 442 is arranged on the inside of the guide block 441 and adopts a flexible connection. The clamp 443 is installed on the inside of the guide block 441 and Interlocking with the adjustment plate 442, the restriction structure 444 is horizontally fixed on the inner upper end of the adjustment board 442 and welded, and the height of the restriction structure 444 is adjusted according to the shape of the handbag for better adaptation.

[0037] refer to Figure 6The limiting structure 444 includes a fixed plate 44a, a pressing structure 44b, a movable plate 44c, and an arc plate 44d, the pressing structure 44b is horizontally fixed on the upper left end of the fixed plate 44a and welded, and the left end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com