Stainless steel side plate welding clamp with weld gaps capable of being adjusted

A welding fixture, stainless steel technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding efficiency, increase the manufacturing cost of fixtures, and the weld gap cannot be adjusted, so as to simplify the operation steps, Guarantee the welding quality and facilitate the effect of synchronous control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

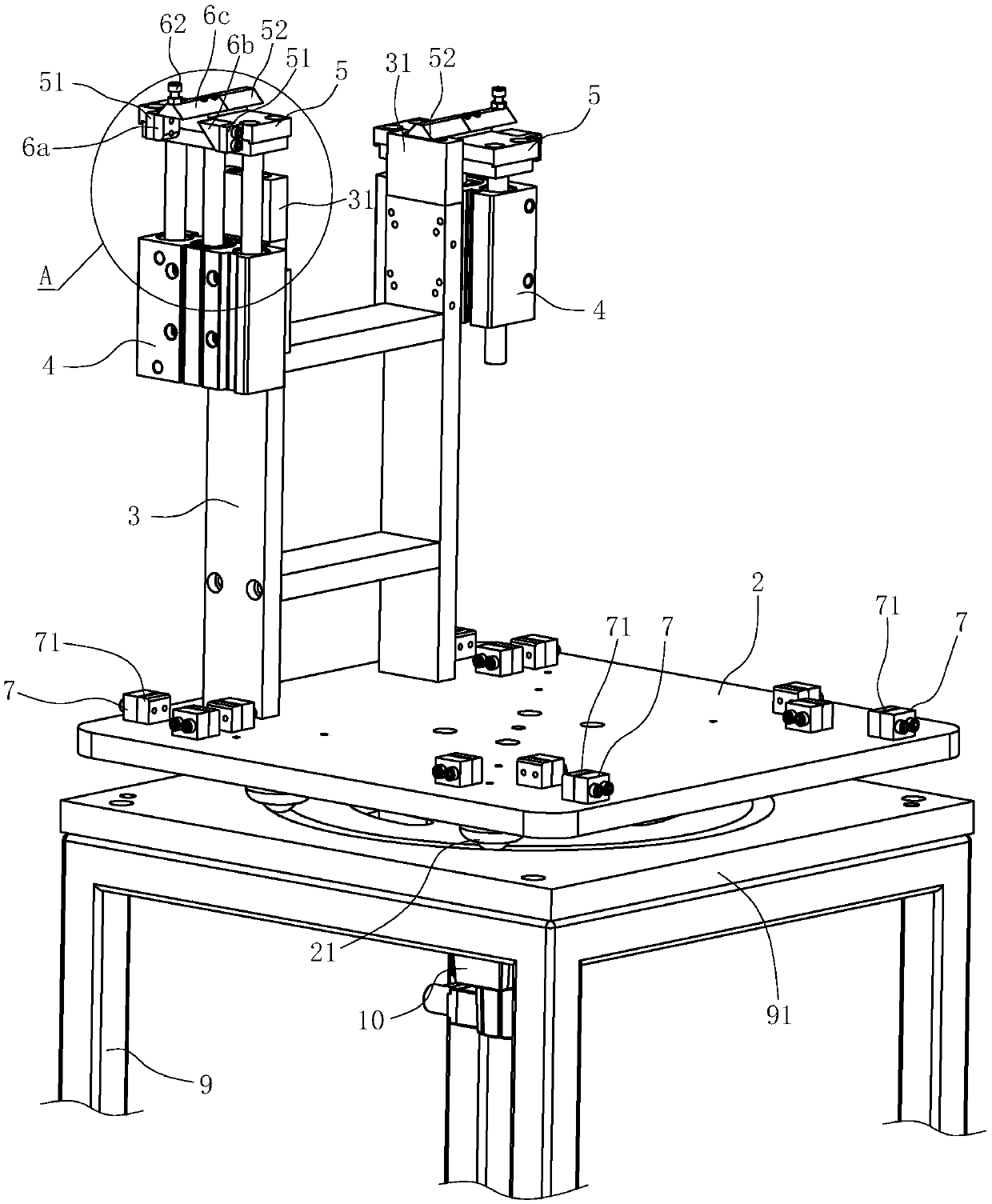

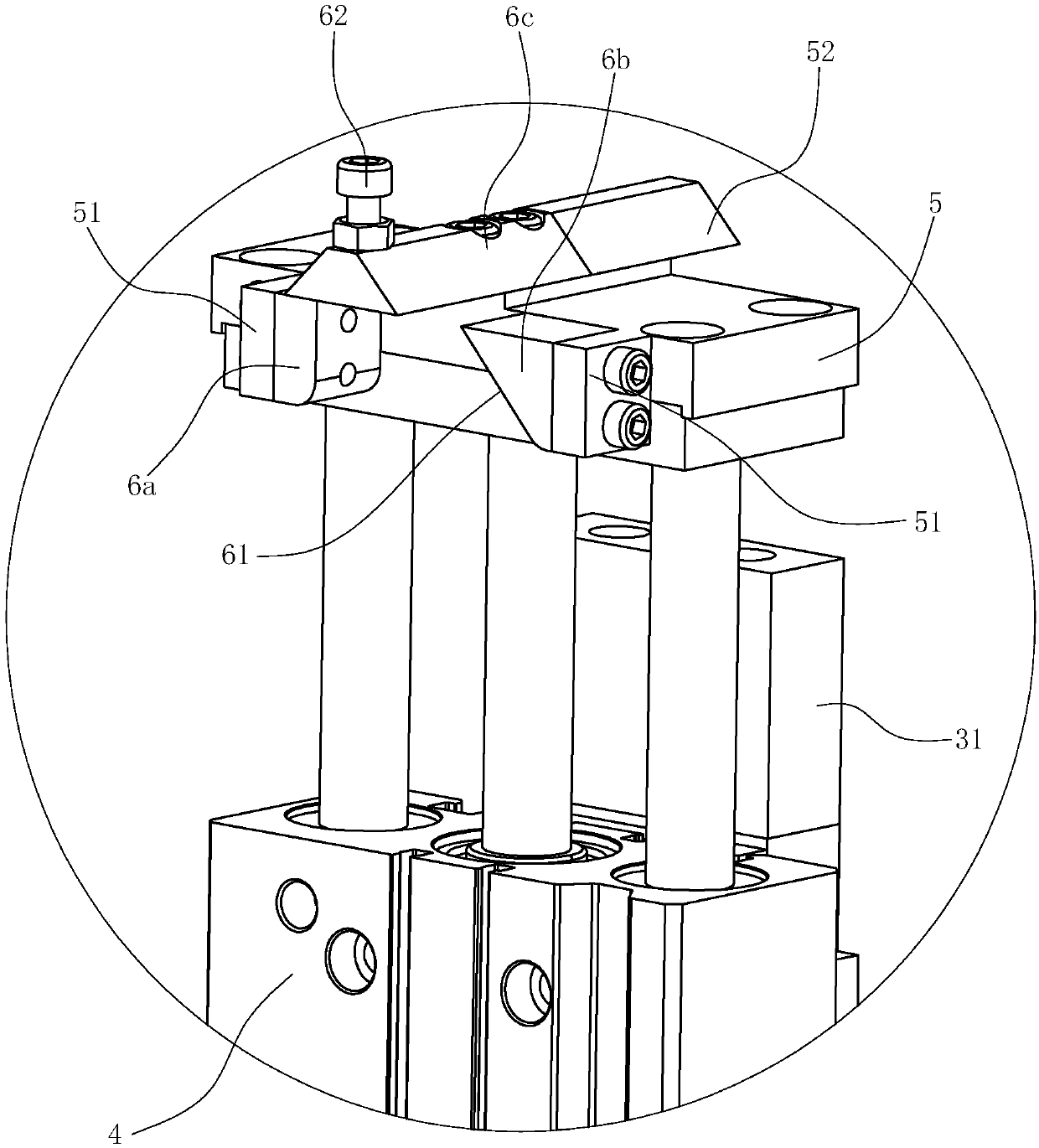

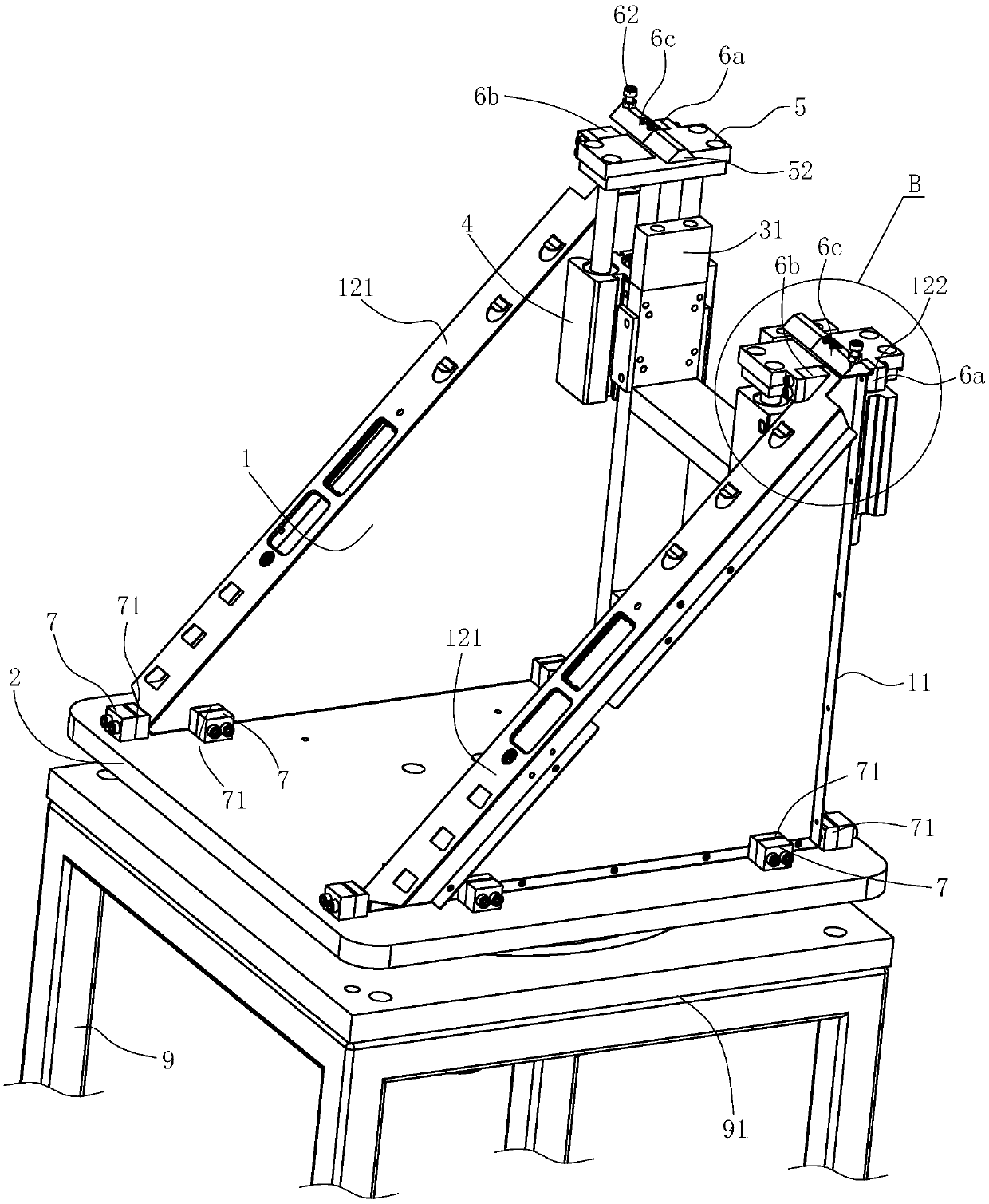

[0023] Such as Figure 1~5 Shown is a preferred embodiment of the present invention.

[0024] A stainless steel side plate welding fixture with adjustable weld seam gap. The stainless steel side plate 1 in this embodiment is in the shape of a right triangle. The stainless steel side plate 1 has two straight folded edges 11 and one oblique folded edge 12. There is a hypotenuse portion 121 and a horizontal edge portion 122 at the top of the hypotenuse portion 121; the horizontal edge portion 122 is welded to the hypotenuse portion 121 and the adjacent straight folded edge 11 respectively, as Figure 5 shown.

[0025] Described welding jig comprises platform 2, and mounting frame 3 is fixed on platform 2, and described platform 2 is provided with two sets of clamping frocks; Located on opposite sides of mounting frame 3 respectively; on the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com