Patents

Literature

90results about How to "Easy to achieve separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering waste thermosetting resin and composite materials thereof through solvents

ActiveCN102617885AReduce usageLess investmentPlastic recyclingBulk chemical productionSolventPolyresin

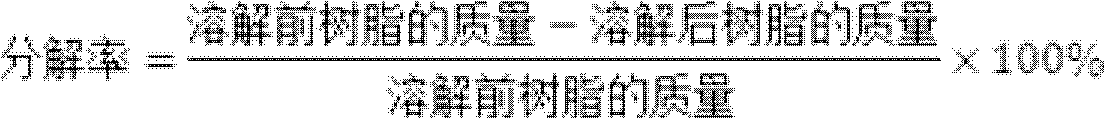

The invention discloses a method for recovering waste thermosetting resin and composite materials thereof through solvents, which includes: adding 100 parts of waste thermosetting resin and composite materials of the waste thermosetting resin and 0-10 parts of catalysts into 10-500 parts of solvents for evenly stirring and mixing, heating the mixture to lead temperature rise to 60-200 DEG C to react for 5-600 minutes, and separating solid phase products and liquid phase products obtained through reaction for recycling. The solvents adopted in the method are environment-friendly, safe and stable and has a capability of degrading thermosetting resin junctions in catalyzing mode so that efficient degradation in conditions of ordinary pressure and low temperature is achieved, energy is saved, expensive reaction devices are not used, investment is small, production cost is low, and simultaneously integral high-value recovery of resin materials can be achieved.

Owner:SICHUAN UNIV

Method for preparing phycocyanin from fresh spirulina

InactiveCN104672325AReduce energy consumptionReduce manufacturing costDepsipeptidesPeptide preparation methodsAmmonium sulfateUltrafiltration

The invention discloses a method for preparing phycocyanin from fresh spirulina. The process design is based on convenience, high efficiency and capability of facilitating comprehensive utilization of different components, the fresh spirulina is used as a processing raw material, and the spirulina phycocyanin is prepared through steps of low-temperature wall breakage, ammonium sulfate fractional salting-out, polyethylene glycol 2000 / (NH4)2SO4 two-aqueous-phase extraction, ultrafiltration and vacuum freezing drying. With the adoption of the method, the yield of the spirulina phycocyanin is higher, the obtained spirulina phycocyanin is low in polysaccharide content, the purity A620 / A280 is about 3.7, the method is applicable to preparation of the phycocyanin from other algae used as raw materials, the biological activity of all components of the spirulina can be well kept during preparation, other obtained separated parts can be further processed, a series of products such as active polysaccharides, chlorophyll, algal protein and the like can be obtained, and the method has the high promotional value and the broad application prospect.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol

InactiveCN104710277AEasy to achieve separationOrganic compound preparationPreparation by OH group eliminationGadolinium oxideGlycerol

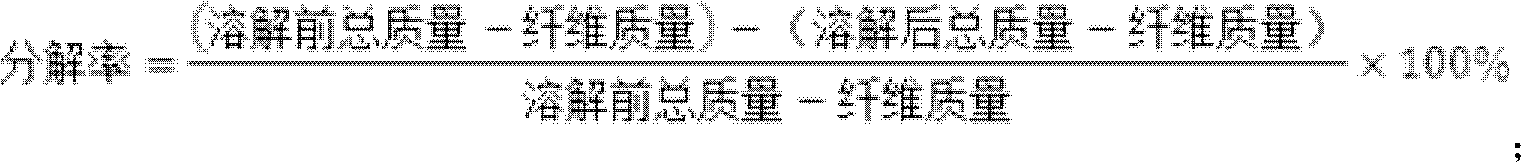

The invention relates to a method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol. The method adopts sugar and sugar alcohol as the raw materials, takes one or more than two of iron, cobalt, nickel, copper, zinc, tin, platinum, ruthenium, palladium, iridium and other transition metals as the catalyst active component, and employs a rare earth oxide like promethium oxide, gadolinium oxide, terbium oxide, holmium oxide, erbium oxide, thulium oxide, cerium oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, scandium oxide, yttrium oxide, dysprosium oxide, europium oxide, samarium oxide, ytterbium oxide, lutecium oxide and the like as the assistant. Under a temperature of 150-320DEG C and an H2 pressure of 1-20MPa, catalytic hydrocracking is carried out in a water solution to obtain ethylene glycol, propylene glycol, glycerol and other low carbon alcohols. The method provided by the invention has the advantages that: the rare earth oxide is added as the assistant to realize hydrocracking of sugar and sugar alcohol, rare earth oxides are insoluble in water and easy to separate, and at the end of reaction, the reaction system has no need for additional acid to neutralize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

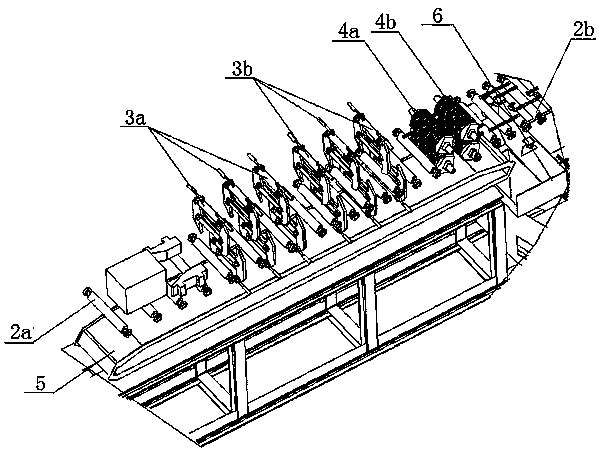

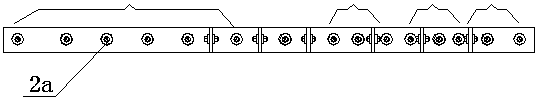

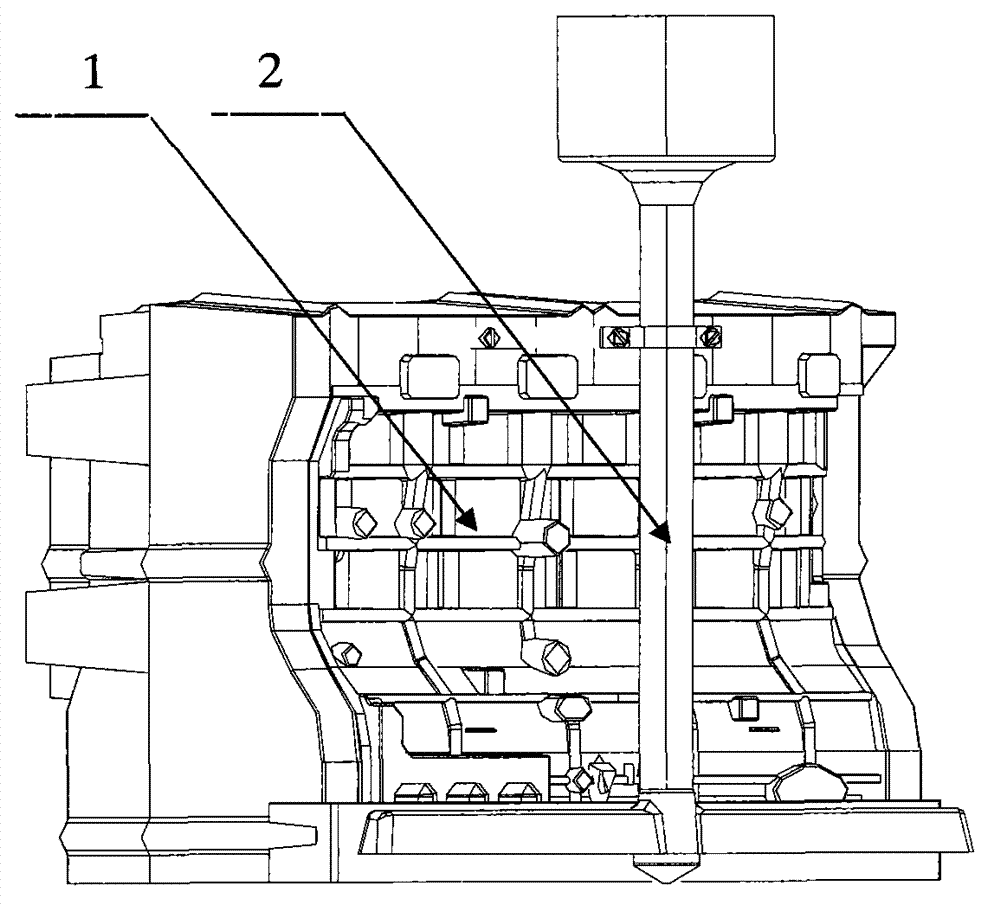

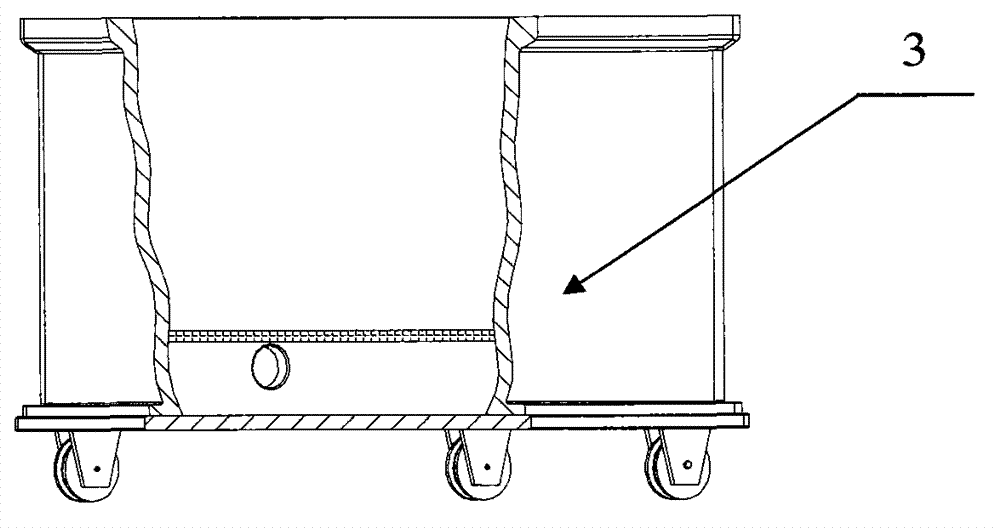

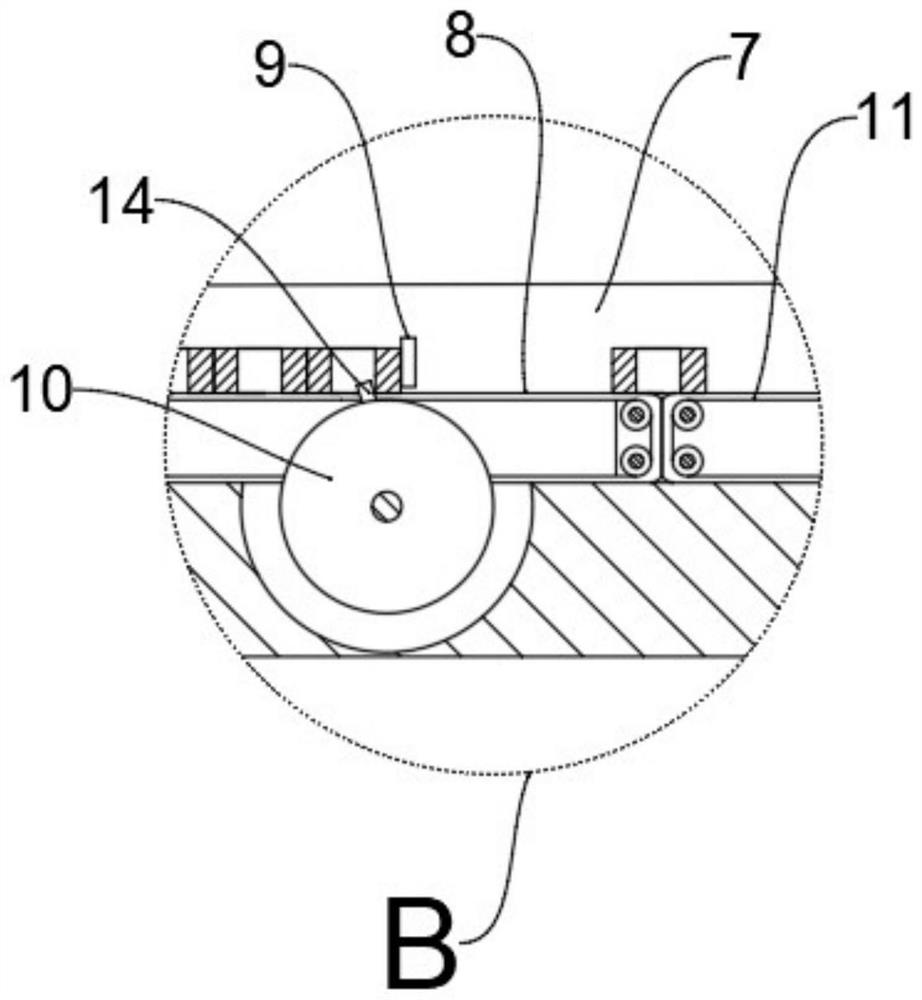

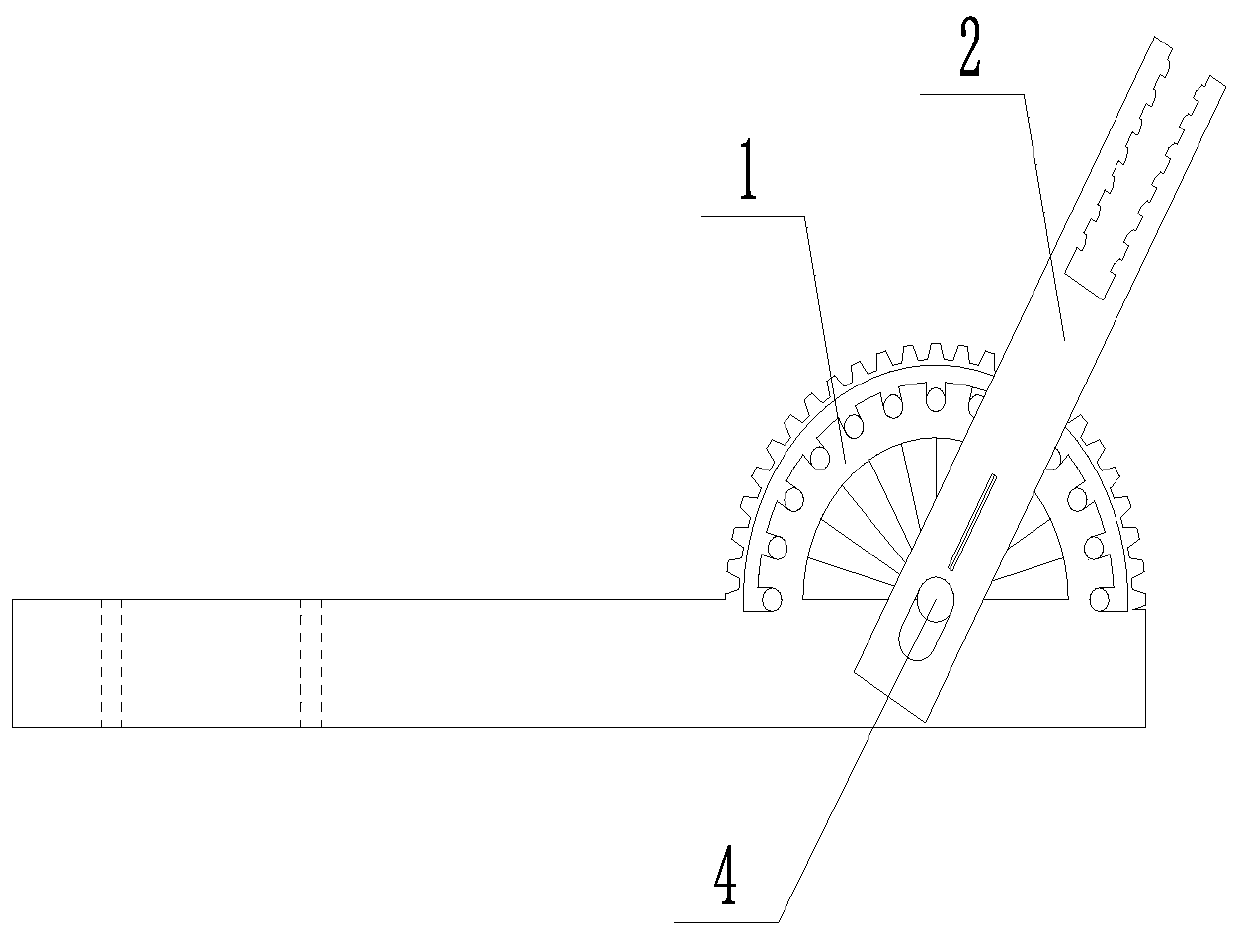

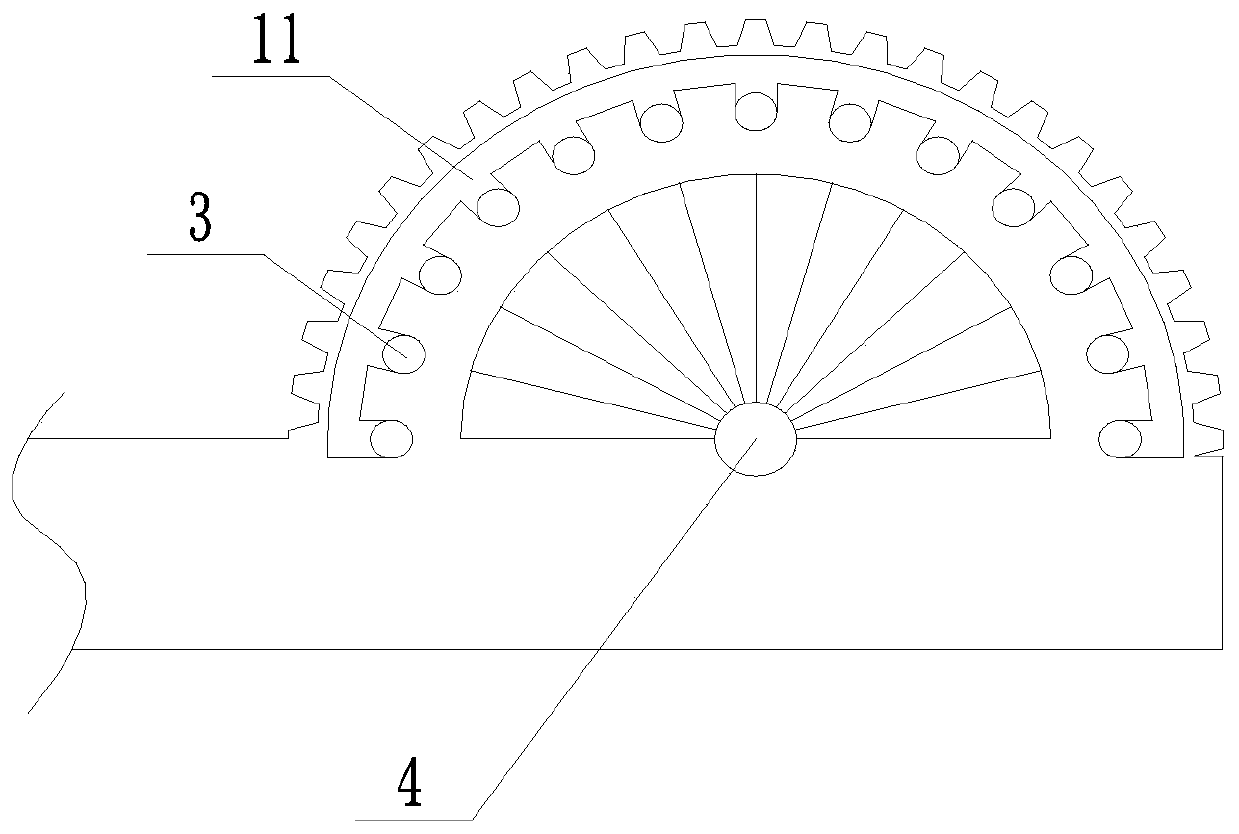

Device for automatically and efficiently crushing reinforced concrete cut material blocks

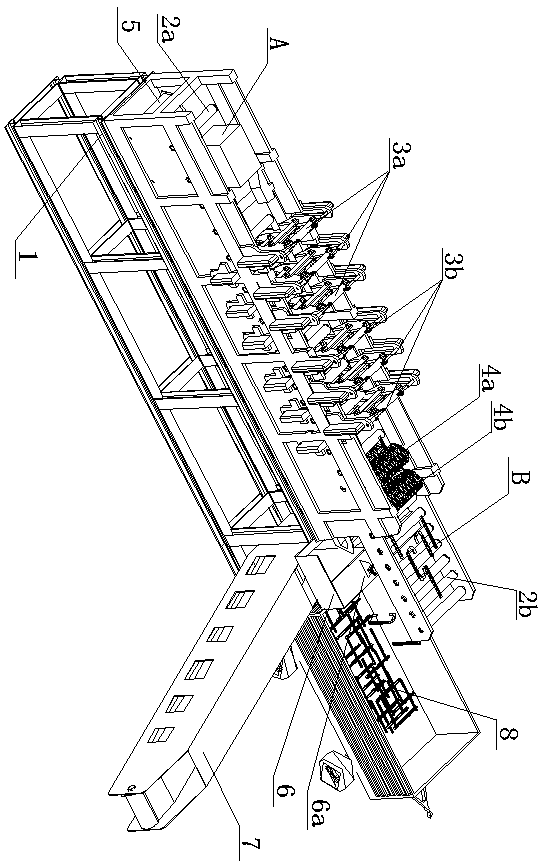

PendingCN108704748AEasy to achieve separationSmall form factorSolid waste disposalGrain treatmentsReinforced concreteEngineering

The invention relates to a device for automatically and efficiently crushing reinforced concrete cut material blocks. A conveying roller table is arranged on a working platform, and comprises a material block crushing roller table and a concrete rib separating roller table; a discharging gap is reserved between adjacent conveying rollers of the material block crushing roller table; the conveying rollers are arranged in a way of being sparse in the front and dense in the rear; a plier force crushing mechanism and a roll compaction crushing mechanism are erected above the material block crushingroller table; a receiving belt conveyor is arranged under the material block crushing roller table; the plier force crushing mechanism comprises a hydraulic plier group sequentially arranged in the material block conveying direction; the roll compaction crushing mechanism comprises a compaction roller group sequentially arranged in the material block conveying direction; the concrete rib separating roller table is arranged outside the working platform in an overhead way; a hopper is arranged at the outlet end of the receiving belt conveyor; a feeding belt conveyor is carried under the hopper;and a selecting chamber for storing reinforcing steel bars is carried at the outlet end of the concrete rib separating roller table. The device provided by the invention can be used for efficiently crushing wastes and effectively separating the reinforcing steel bars and the concrete, and is the concrete material block cutting device with a high popularization value and a wide application range.

Owner:HEBEI ZHUOQIU IND CO LTD

Pouring production process used for automobile engine casting combined core

InactiveCN102921897ALow investment costReduce production and operation costsFoundry mouldsMould handling/dressing devicesOperational costsDry sand

The invention provides a box-type dry sand filling pouring production process used for an automobile engine iron casting cold core box combined core, wherein the combined core is fully filled by utilizing dry sand and auxiliary filler in a sand box having a vacuumizing structure so as to provide support for a skin core, and a measure of vacuumizing to further improve the support strength to the skin core is reserved so as to ensure that the combined core is poured in the condition of meeting the process strength requirement in the casting pouring and solidifying process, thereby realizing cooling of the casting in the box. The invention provides a new process which can conveniently solve the technical problem, can realize automatic flow line production suitable for batch production, and simultaneously can fully utilize the technical characteristics of the combined core; is strong in product adaptability, can effectively reduce equipment investment, can effectively save production and operation cost, is environment-friendly, economical, friendly in operation environment and practical, and can produce castings with high quality and high precision.

Owner:贺秉祥

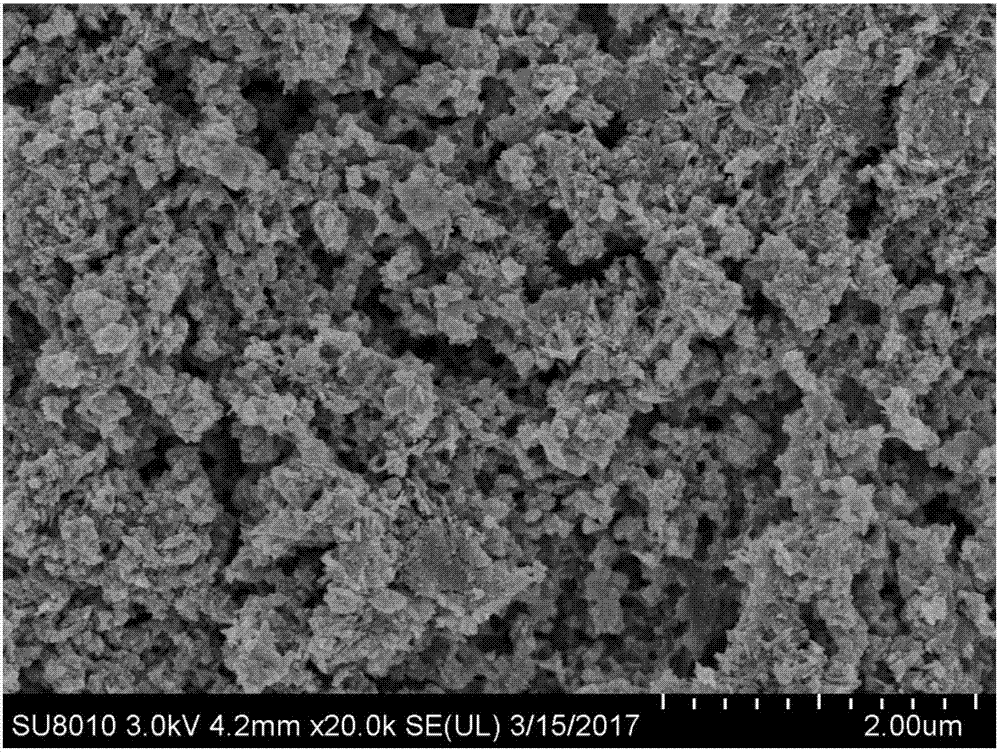

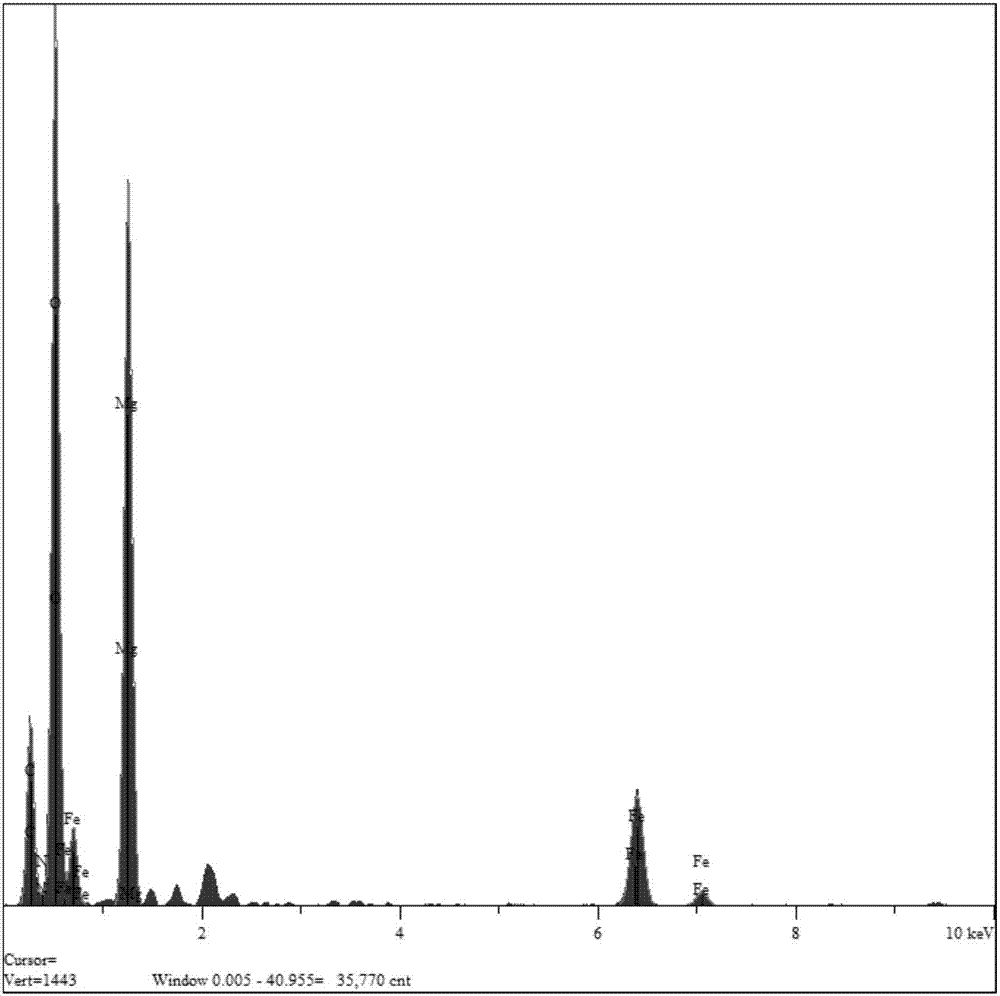

Magnetic magnesium hydroxide adsorbent and preparation method thereof

ActiveCN107081123AEasy to manufactureEasy to controlOther chemical processesWater contaminantsIron saltsEmulsion

The invention discloses a magnetic magnesium hydroxide adsorbent and a preparation method thereof. The magnetic magnesium hydroxide adsorbent is loaded on porous magnesium hydroxide as a carrier and filled with nano Fe3O4 particles. The preparation method comprises the following steps: (1) dropwise adding an NaOH solution to a micro emulsion system containing MgSO4 for preparing the porous magnesium hydroxide; and (2) dissolving the porous magnesium hydroxide carrier in absolute ethyl alcohol, conducting ultrasonic dispersion, adding an iron salt solution, and regulating the pH value of the obtained mixed solution to 10-11 under the conditions of inert-gas protection and stirring to obtain the magnetic magnesium hydroxide adsorbent. The preparation method disclosed by the invention has a simple process and low cost, and the prepared adsorbent has strong adsorption properties on heavy metals and organic pollutants, and also has the advantages of big adsorption capacity, easy separation and the like.

Owner:HUNAN AGRICULTURAL UNIV

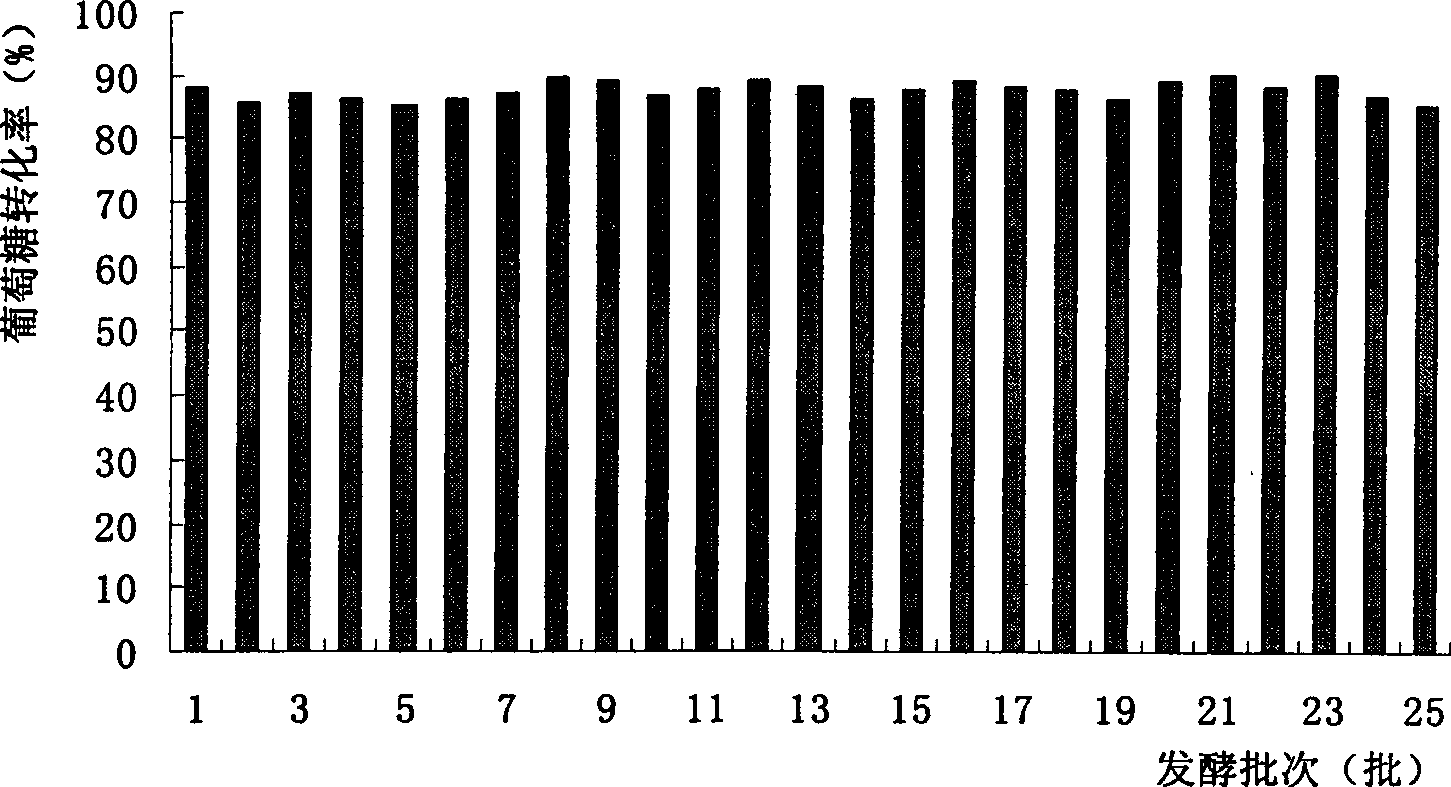

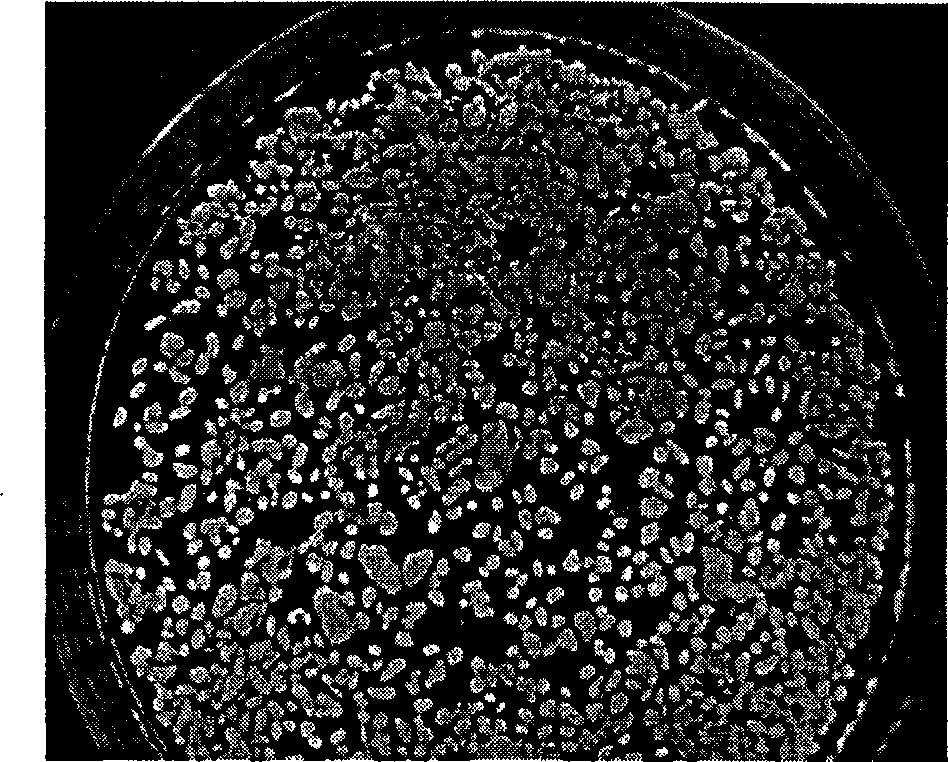

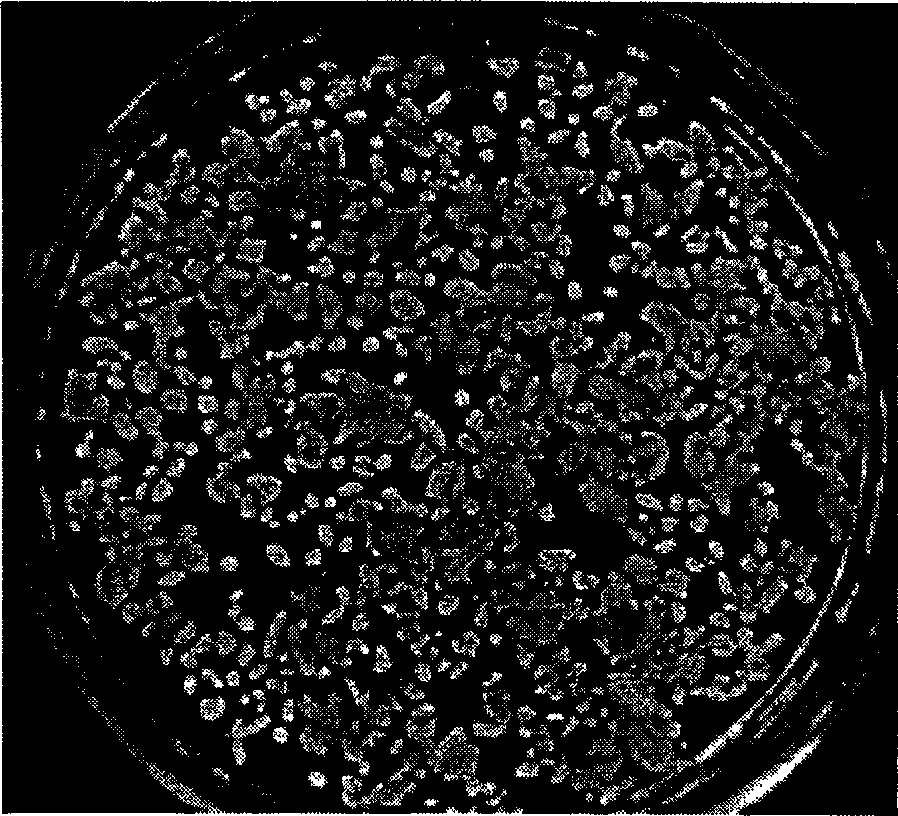

Novel technological process for producing high optical purity L-lactic acid by semi-continuous high-density fermentation of Rhizopus oryzae

InactiveCN101497901AIncrease the cell concentrationIncrease fermentation intensityMicroorganism based processesFermentationChemistryNovel technique

The invention discloses a novel technique for producing high optical purity L-lactic acid through rhizopus oryzae high cell density fermentation by a semi-continuous way, which relates to the following steps: (1) preparing rhizopus oryzae spore suspension; (2) preparing seed culture; (3) high-density thalli amplification; (4) 500L fermentation cylinder for the first batch fermentation; (5) 500L fermentation cylinder for high-density fermentation by the semi-continuous way-the first 5 times thalli proliferation and repeat fermentation; and (6) the last 20 times 500L fermentation cylinder for high-density and high-intensity repeat fermentation. The technique realizes semi-continuous fermentation by repeatedly using rhizopus oryzae thallis and increases the use ratio of raw material; the thallis are constructed in high density so that the fermentation period is shortened to be 18h and the fermentation intensity is increased to be 5.0g / (h*L), thus the technique has good industrial production prospect; the optical purity of the fermentation product of L-lactic acid is over 99.5 percent so as to satisfy the demands of foods and medicaments; and the existing demand for high-purity L-lactic acid is relieved to a great extent after industrial production.

Owner:HEFEI UNIV OF TECH

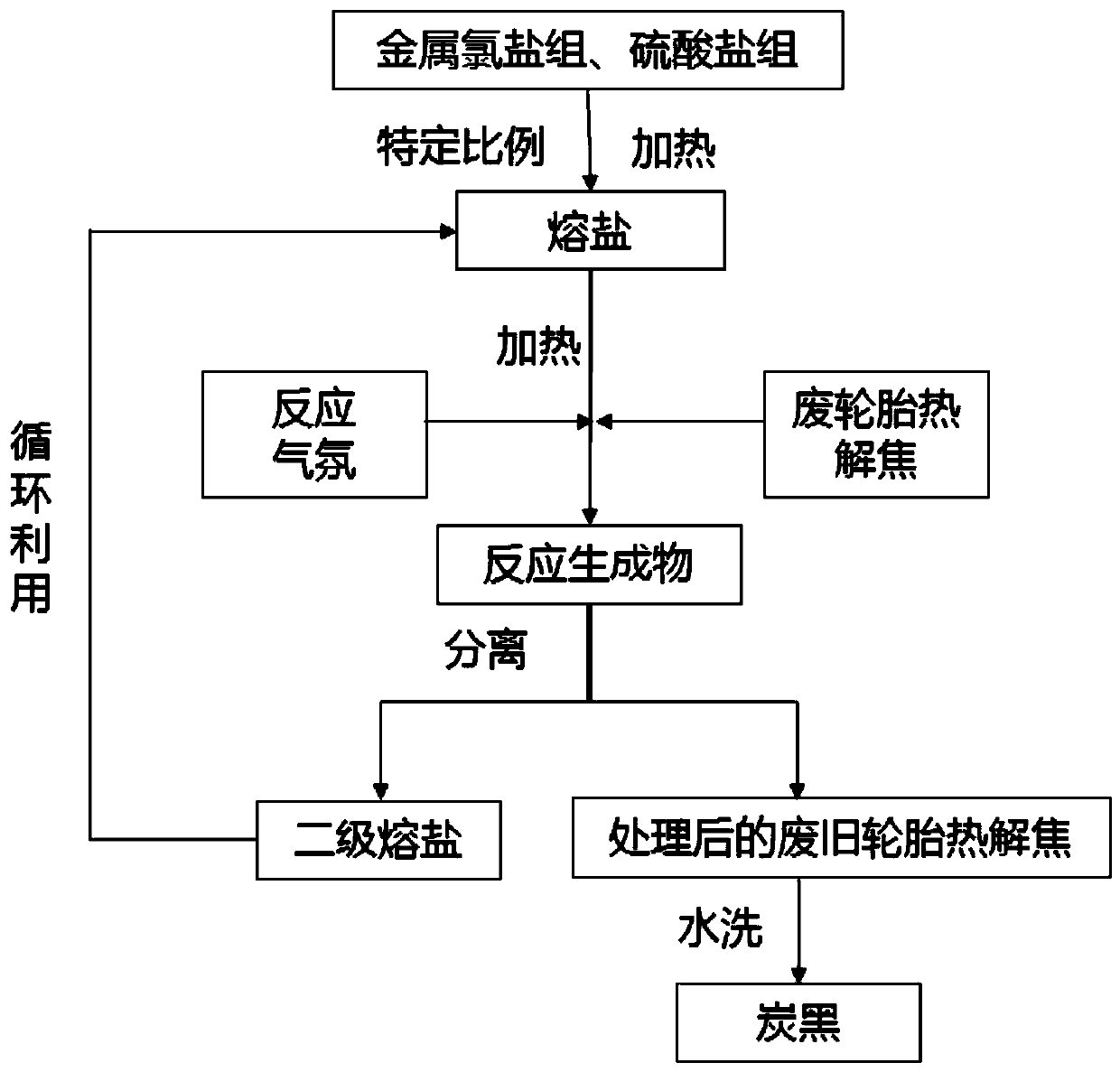

Method for preparing carbon black from pyrolysis coke of waste tire through molten salt heat treatment, and product prepared by using the same

ActiveCN110229543AEnhanced low temperature melting propertiesHigh activityPigmenting treatmentStrong acidsImpurity

The invention belongs to the technical field of resourceful utilization of organic solid wastes, and specifically discloses a method for preparing carbon black from pyrolysis coke of a waste tire through molten salt heat treatment, and a product prepared by using the same. The method comprises the following steps: heating one or two selected from the group consisting of a metal chloride salt groupand a metal sulfate salt group so as to obtain molten salt; adding the pyrolysis coke of the waste tire into the molten salt, and carrying out molten salt heat treatment under a preset reaction atmosphere; and after completion of a reaction, separating a reaction product into secondary molten salt and treated pyrolysis coke, washing treated pyrolysis coke with hot water, carrying out drying so asto obtain the carbon black, and recycling the secondary molten salt at the same time. According to the invention, by utilization of the melting characteristic of the molten salt, impurity componentsin the pyrolysis coke of the waste tire are dissolved out, so the use of strong acids and strong alkalies like nitric acid, hydrochloric acid and an alkali liquor is avoided; meanwhile, through addition of metal chloride salt, the low-temperature melting characteristic of the molten salt is reinforced; and by utilization of metal sulfate salt, acidic gases like hydrogen sulfide and hydrogen chloride are captured in situ at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

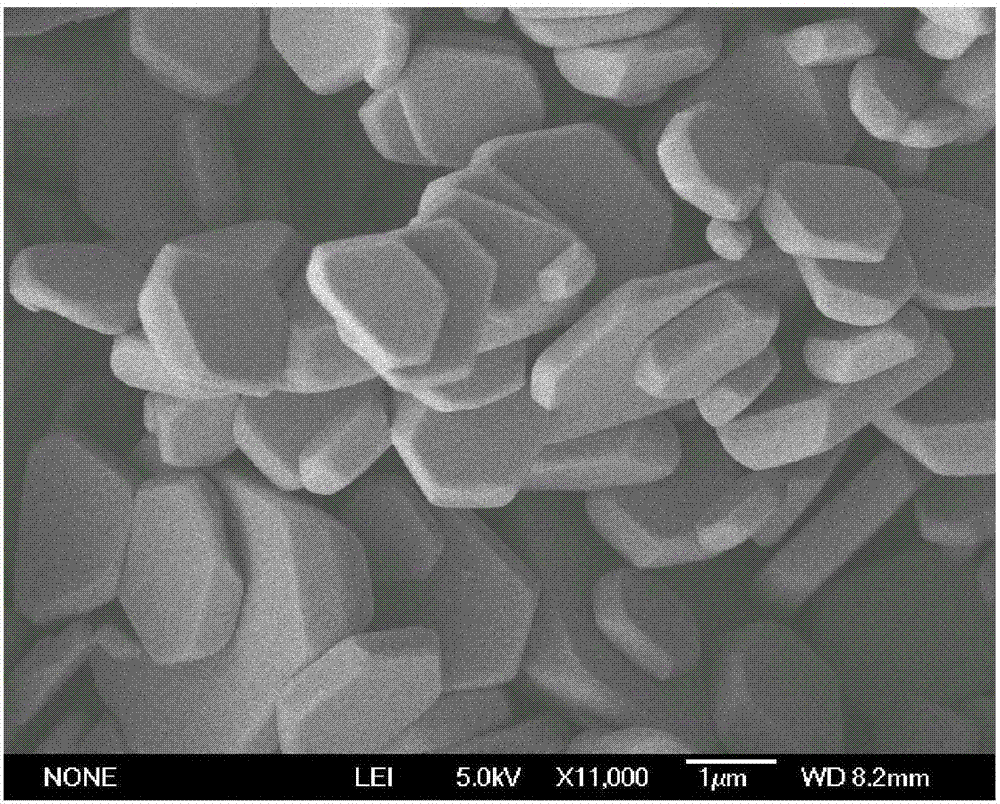

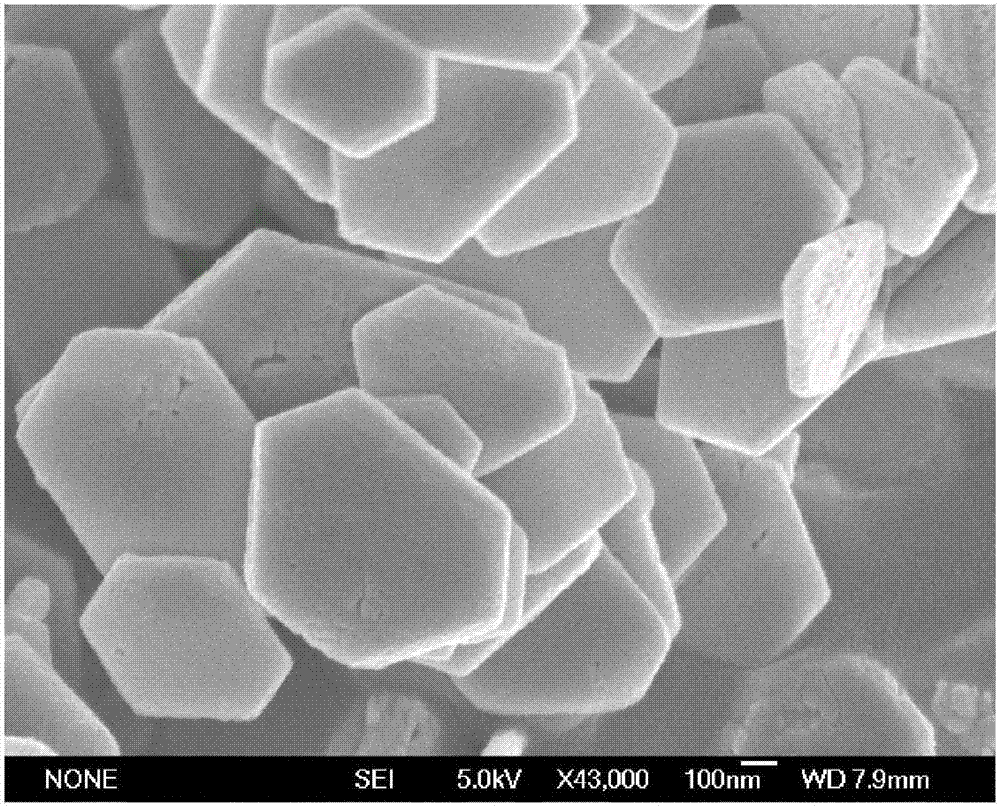

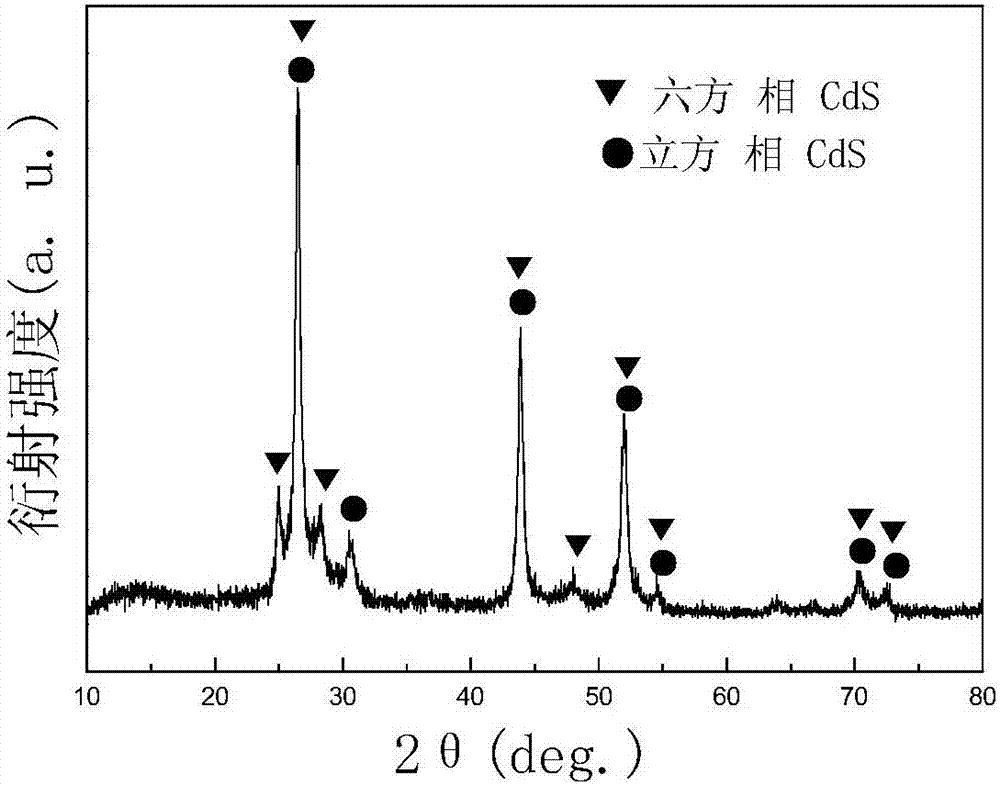

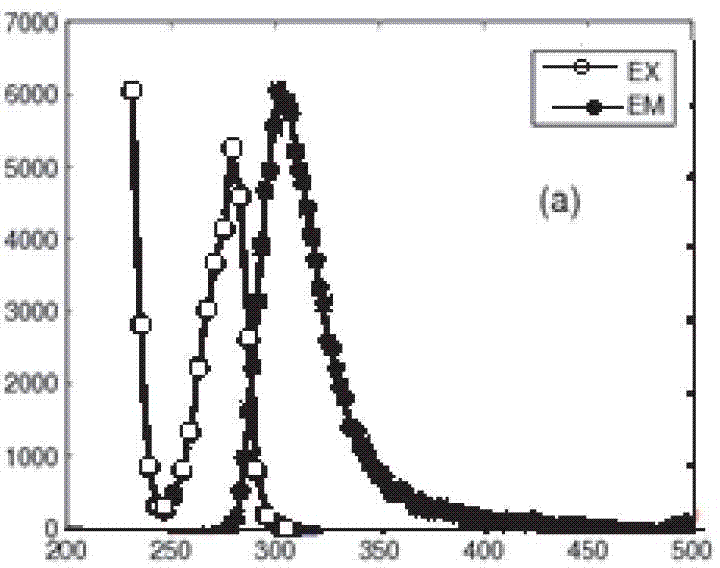

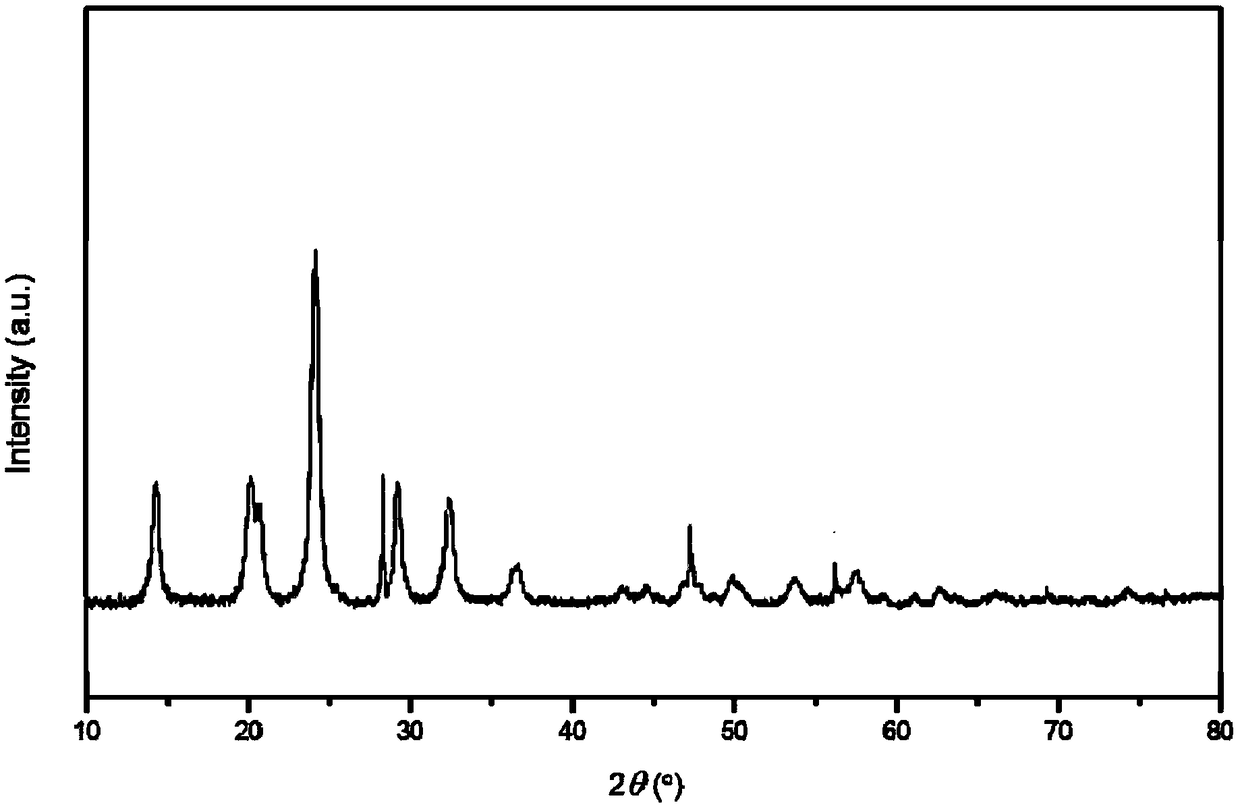

Preparation method of mixed crystal phase heterojunction nano-cadmium sulfide with special morphology

ActiveCN107138167AReduce compoundingEasy to achieve separationPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionPotassium dichromate

The invention relates to a preparation method of mixed crystal phase heterojunction nano-cadmium sulfide with a special morphology. The preparation method comprises the following steps: preparing a precursor cadmium hydroxide by a solvothermal method; obtaining nano-cadmium oxide by calcination; then, vulcanizing the prepared nano-cadmium oxide by a hydrothermal method to synthesize nano-cadmium sulfide of a cubic-hexagonal mixed crystal phase; and washing and drying the product to obtain the mixed crystal phase heterojunction nano-cadmium sulfide, wherein the morphology characteristics are shown as cadmium sulfide nano-particles with particle size of 20-50 nm and cadmium sulfide nano-rods with length of 60-120 nm and diameter of 10-25 nm. The obtained mixed crystal phase heterojunction nano-cadmium sulfide is used as a photocatalyst for degrading potassium dichromate solution and has excellent photocatalytic degradation performance.

Owner:QUFU NORMAL UNIV

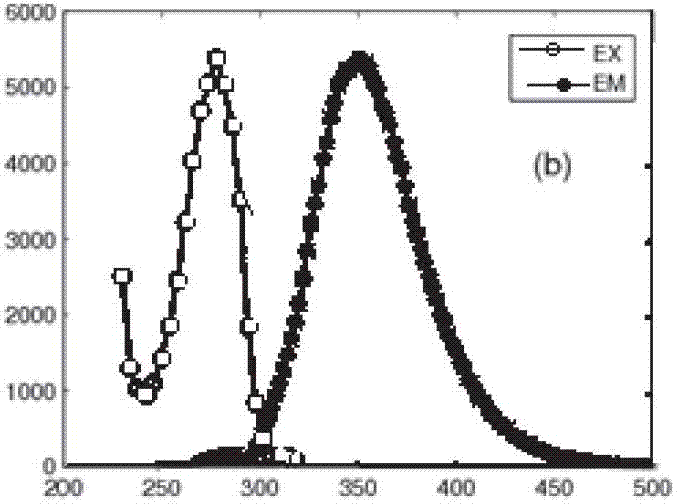

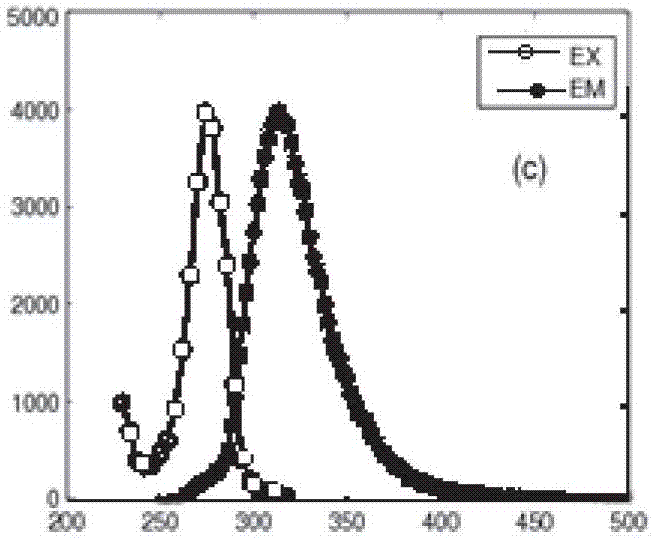

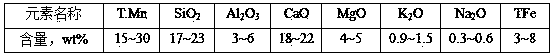

Multi-component three-dimensional fluorescence aliasing spectrum data processing method based on differential spectrum

ActiveCN102967589AEasy accessHigh-resolutionFluorescence/phosphorescenceDifferential spectrumFluorescence spectrometry

The invention discloses a data processing method for effectively solving a multi-component overlapped three-dimensional fluorescence spectrum based on differential spectrum. The method comprises the following steps of: by carrying out two-dimensional expansion on a three-dimensional fluorescence spectrum and expanding the three-dimensional fluorescence spectrum into a excitation spectrum and a transmission spectrum; respectively calculating differential spectrums of the excitation spectrum and the transmission spectrum; before carrying out the differential spectrum calculation on the excitation spectrum and the transmission spectrum, carrying out cubic spline interpolation on the excitation spectrum, and carrying out roughness punishment smoothing treatment on the transmission spectrum; and finally carrying out independent component analysis to realize the accurate component identification and single component extraction of a multi-component mixture, thereby realizing the precise separation of a multi-component three-dimensional fluorescence severe overlapped spectrum and the accurate identification and extraction of the components. The method is applicable to data processing on all multi-component three-dimensional fluorescence aliasing spectrums which use a three-dimensional fluorescence spectrum technique as analysis means; method basis for further application of the three-dimensional fluorescence spectrum technique is provided, and the method has very wide application prospect.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

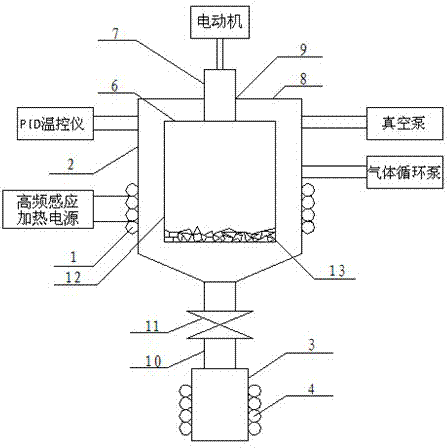

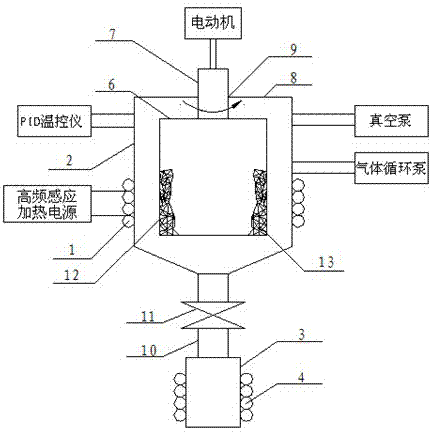

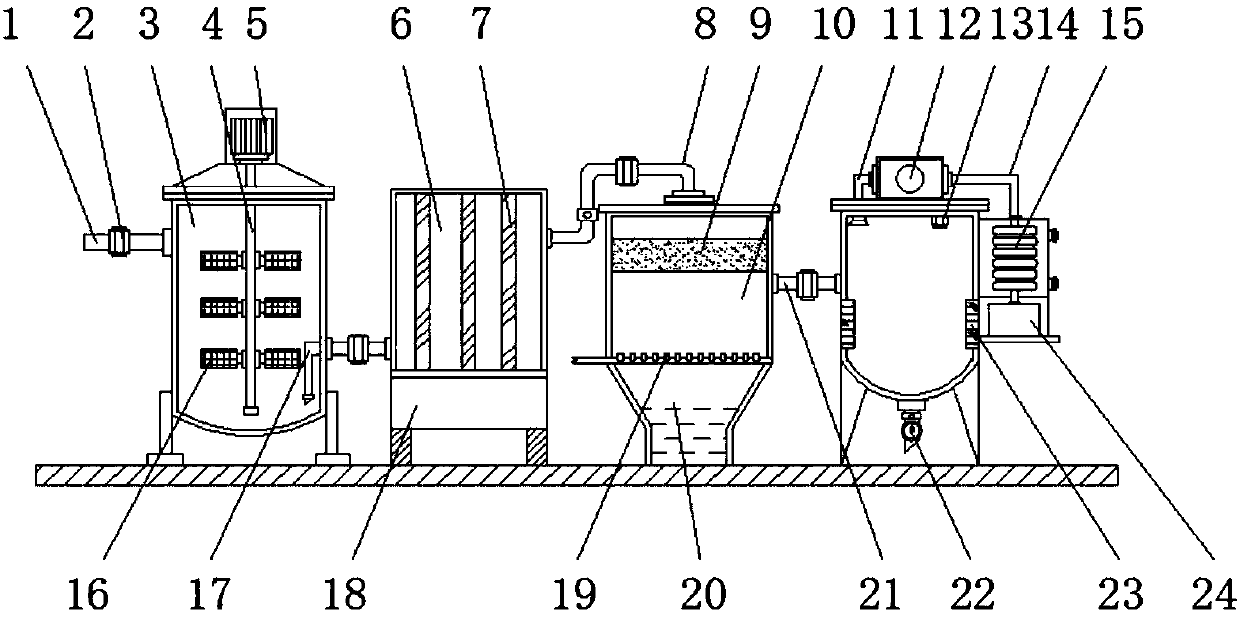

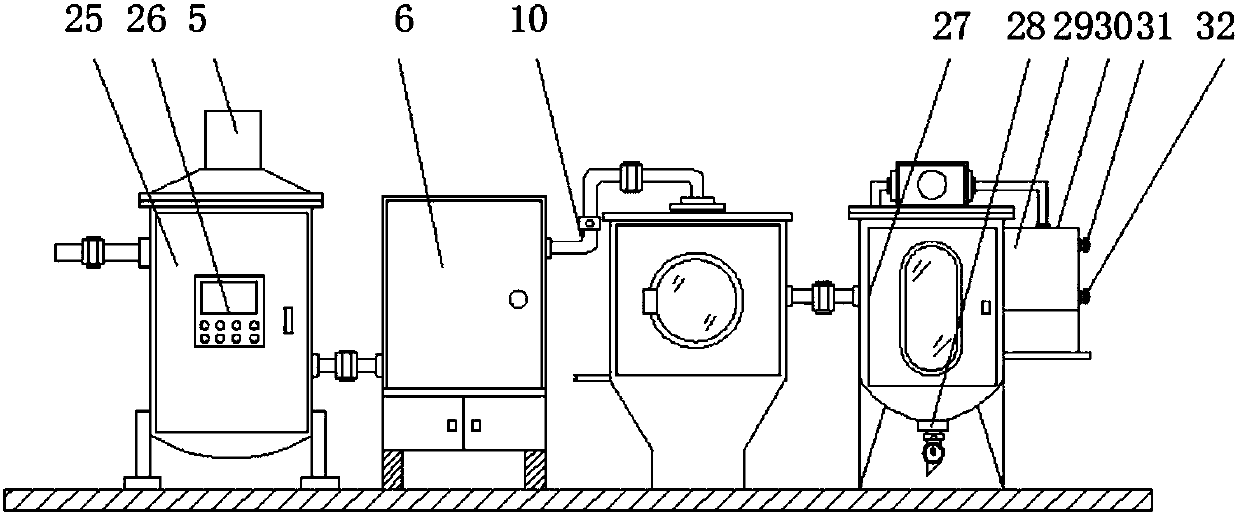

Waste circuit board metal recovering device based on high-frequency induction heating principle

The invention relates to a waste circuit board metal recovering method and a recovering device based on the high frequency induction heating principle. The recovering method comprises the steps that a crucible is driven to rotate by an electric motor; an induction coil is electrified, the waste circuit board fragment metal in the crucible is heated under the action of electromagnetic induction, the metal under a rotation state clings to the inner wall of the crucible, and the metal shows a molten state after achieving a melting point; the metal under centrifugal force enters a cavity between the crucible and another crucible, then flows into a material collection bottle along the inner wall of the cavity, and finally is cooled by a device.

Owner:JILIN UNIV

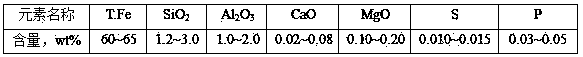

Method for preparing manganese-iron alloy based on low-grade manganese ore

The invention discloses a method for preparing a manganese-iron alloy based on low-grade manganese ore. The method comprises four processes, namely ball milling of raw materials, pelletizing, quick reduction and slag-metal separation. The method comprises the following steps: mixing low-grade manganese ore and iron ore powder; milling the mixed ore, and screening with a 150-300 meshes screen; mixing the screen underflow with the pulverized coal, lime, bentonite and water, and pelletizing on a disc type pelletizer, wherein the diameter of the green balls is 10-16mm; drying the green balls at 105 DEG C for 4h; reducing the dried pellets at 1,450-1,550 DEG C for 8-15min; and after the reaction, crushing the raw material, and performing simple magnetic separation to obtain granular manganese iron, wherein the manganese content is 45-70%, the iron content is 25-45%, the carbon content is 2-5%, and the balance is impurities. According to the method disclosed by the invention, the manganese-iron alloy is prepared by the one-step process of the quick reducing technology, the slag and metal are easily separated, the process is pollution-free, the manganese recovery rate is high, and high value-added utilization of the low-grade manganese ore is realized.

Owner:SUZHOU UNIV

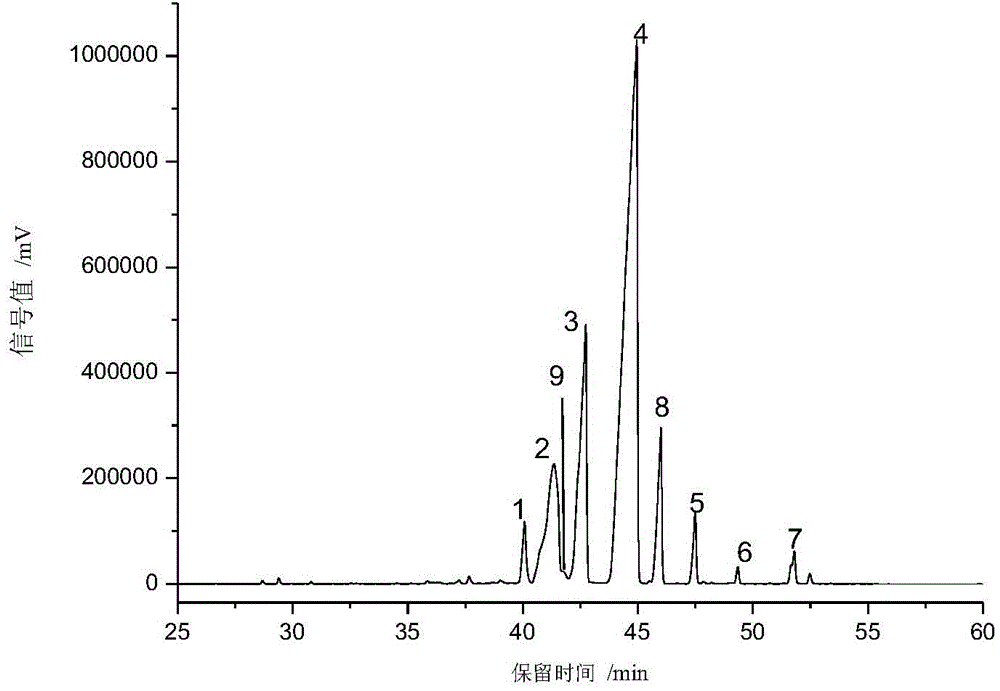

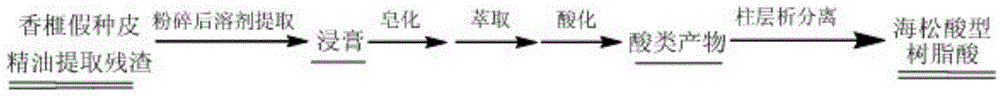

Pimaric acid type resin acid product and method for extracting pimaric acid type resin acid product from torreya grandis aril

ActiveCN104099023AEasy to separate and purifyImprove qualityNatural resin chemical modificationNatural resin purificationSolventAmount of substance

The invention discloses a pimaric acid type resin acid product and a method for extracting the pimaric acid type resin acid product from torreya grandis aril. The method includes the following steps: residues obtained by extracting torreya grandis aril essential oil is used as raw material, and ethyl alcohol, methylbenzene or hexane is used as a solvent; reflux extraction is performed, and separation is performed for removing the solvent, so that a paste extract is obtained; the paste extract is dissolved in water, a sodium hydroxide aqueous solution or a potassium hydroxide aqueous solution is added for saponification, so that acids such resin acid and other esters are converted into water-soluble resin acid salts; the water-soluble resin acid salts are extracted by an organic solvent to enable the water-soluble resin acid salts to be separated from non-acid substances, resinate in the obtained aqueous solution is converted into free resin acid by hydrochloric acid or sulfuric acid, and the free resin acid is separated out from the solution, and the obtained free resin acid is subjected to column chromatography isolation and purification, so that a pimaric acid type resin acid mixture product is obtained. The main component of the product is pimaric acid type resin acid, and meanwhile, the product contains less secondary component abietic acid type resin acid.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

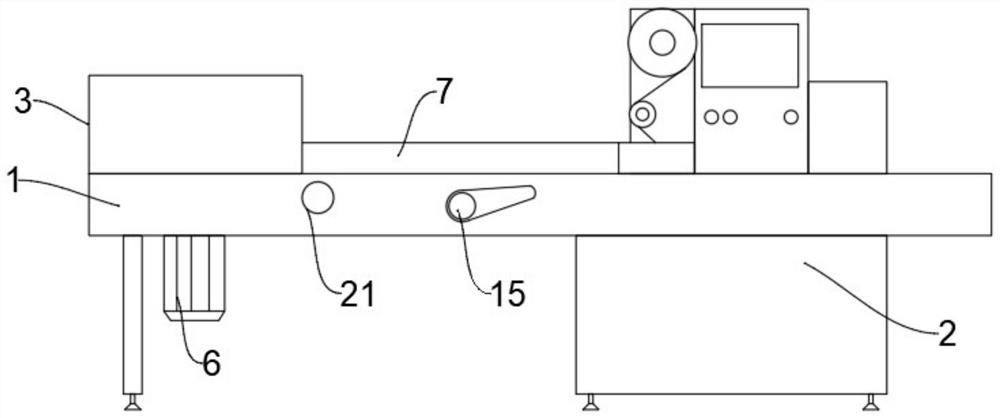

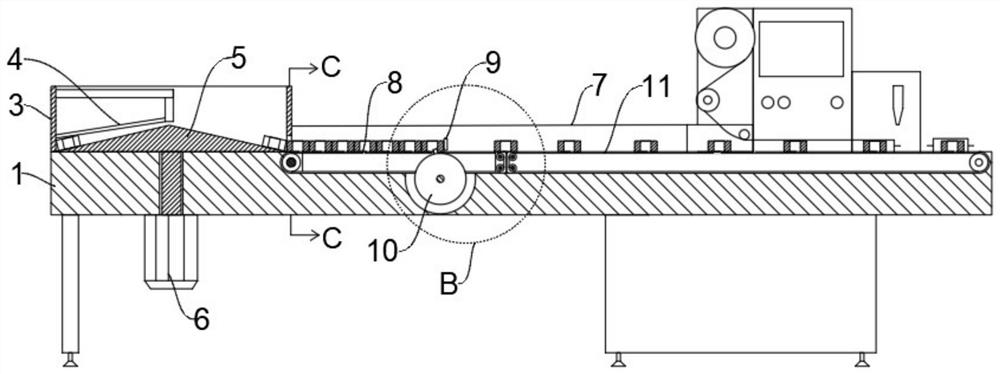

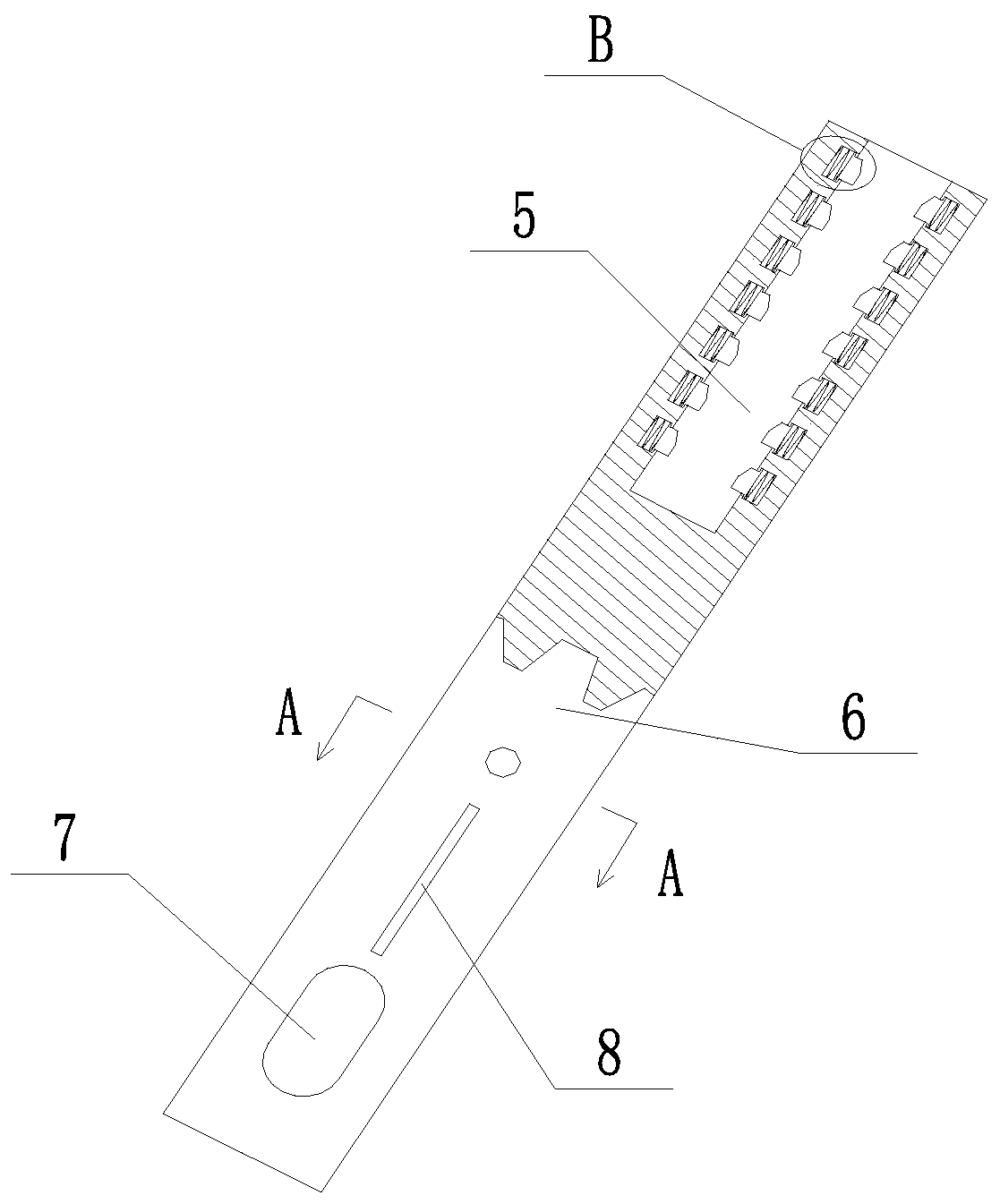

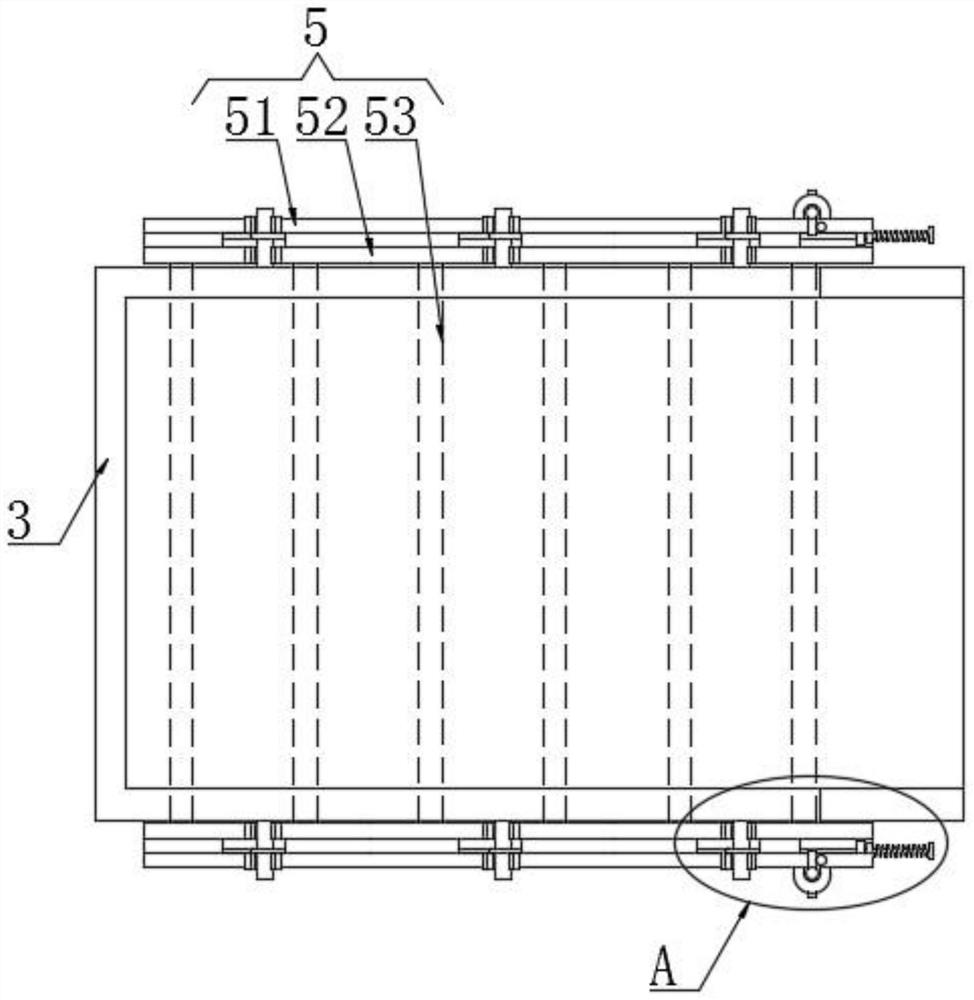

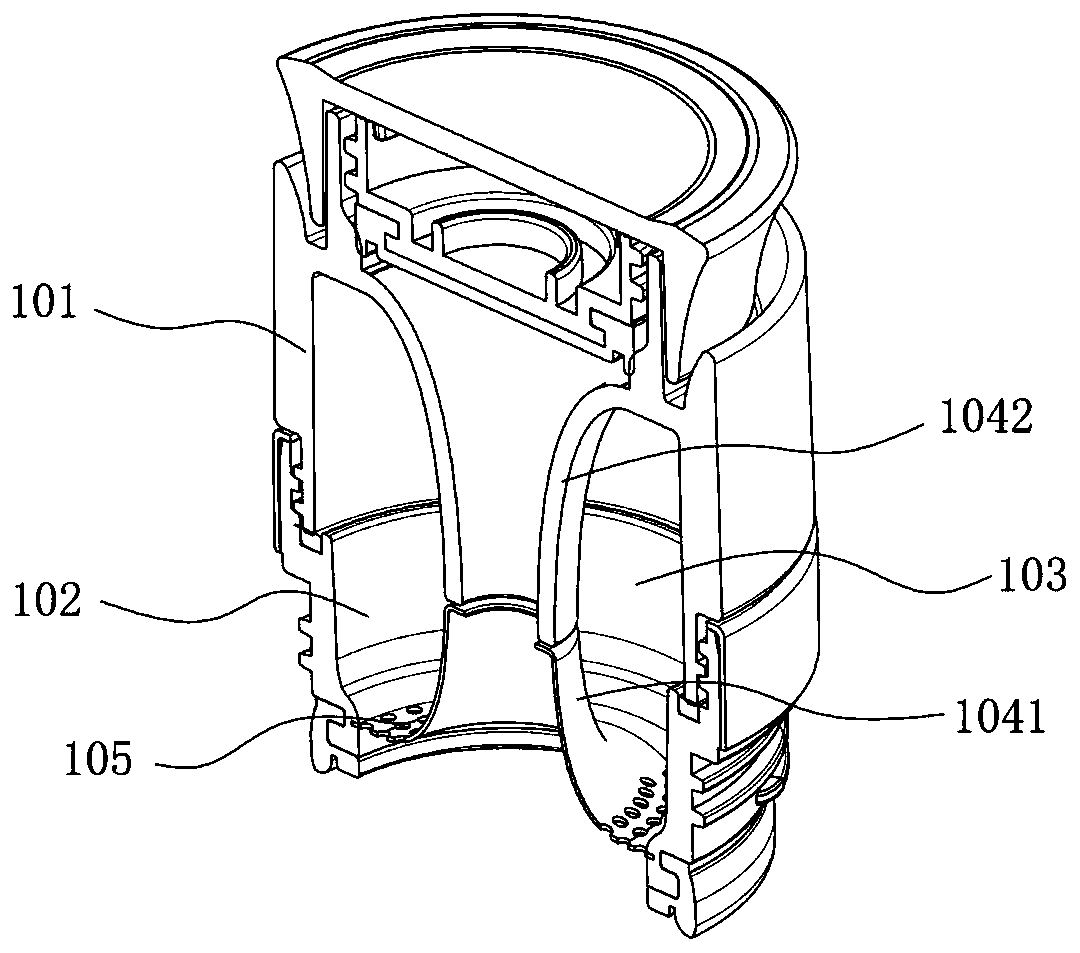

Bearing counting packaging machine

ActiveCN111731556AEasy to control synchronouslyEasy to achieve separationPackaging automatic controlPackaging machinesStructural engineeringIndustrial engineering

The invention relates to a bearing counting packaging machine. The bearing counting packaging machine comprises a rack, a placing mechanism, a pre-conveying device, a separating device and a packagingmachine body, the placing mechanism is fixed to one end of the upper surface of the rack, the packaging machine body is fixed to the other end of the upper surface of the rack, a discharging outlet of the placing mechanism directly faces one end of the pre-conveying device, and the other end of the pre-conveying device directly faces the feeding end of the packaging machine body. During using, aworker can directly place bearing parts into the placing mechanism, the bearing parts are preliminarily arranged under the action of internal components of the placing mechanism and then slide from the discharging outlet of the placing mechanism onto a pre-conveying belt of the pre-conveying device, the multiple bearing parts are linearly arranged on the pre-conveying belt, then the bearing partsare conveyed onto a feeding conveying belt of the packaging machine body at equal intervals through the separating device, the bearing parts are packaged at the next step, and the whole process can befully automated.

Owner:WUXI YUANTONG BEARING CO LTD

Refining slag for purifying and de-aluminizing silicon iron, and preparation method

ActiveCN110157860ALow melting pointLow densityProcess efficiency improvementSmelting processFerrosilicon

The invention discloses a refining slag for purifying and de-aluminizing silicon iron, and a preparation method. According to the refining slag for de-aluminizing the silicon iron prepared through themethod, not only can the preparation cost be reduced, but also a melting point and the density of the refining slag can be greatly reduced, the slag-gold separation can be easily realized, common silicon iron with a high aluminum content with relatively low cost can be treated into low-aluminum silicon iron with relatively high cost, and the use cost of the alloy in the smelting process is further reduced. Meanwhile, wastes produced in the continuous casting production process are used for preparing the refining slag so as to be high-efficiently and reasonably utilized, so that the sustainability of resources is realized.

Owner:ANGANG STEEL CO LTD

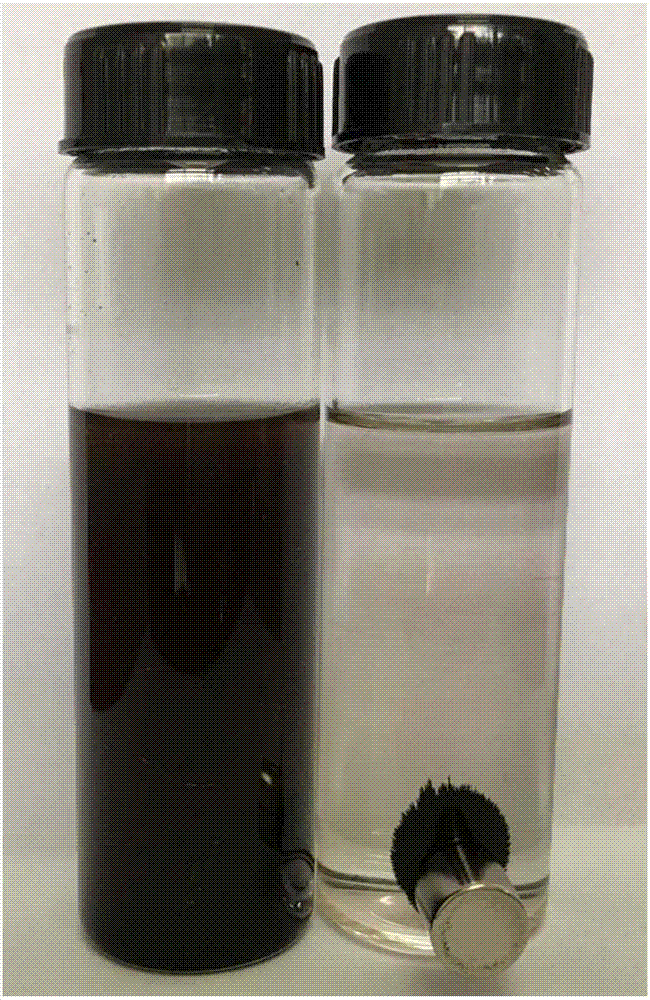

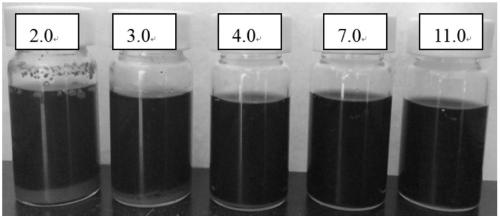

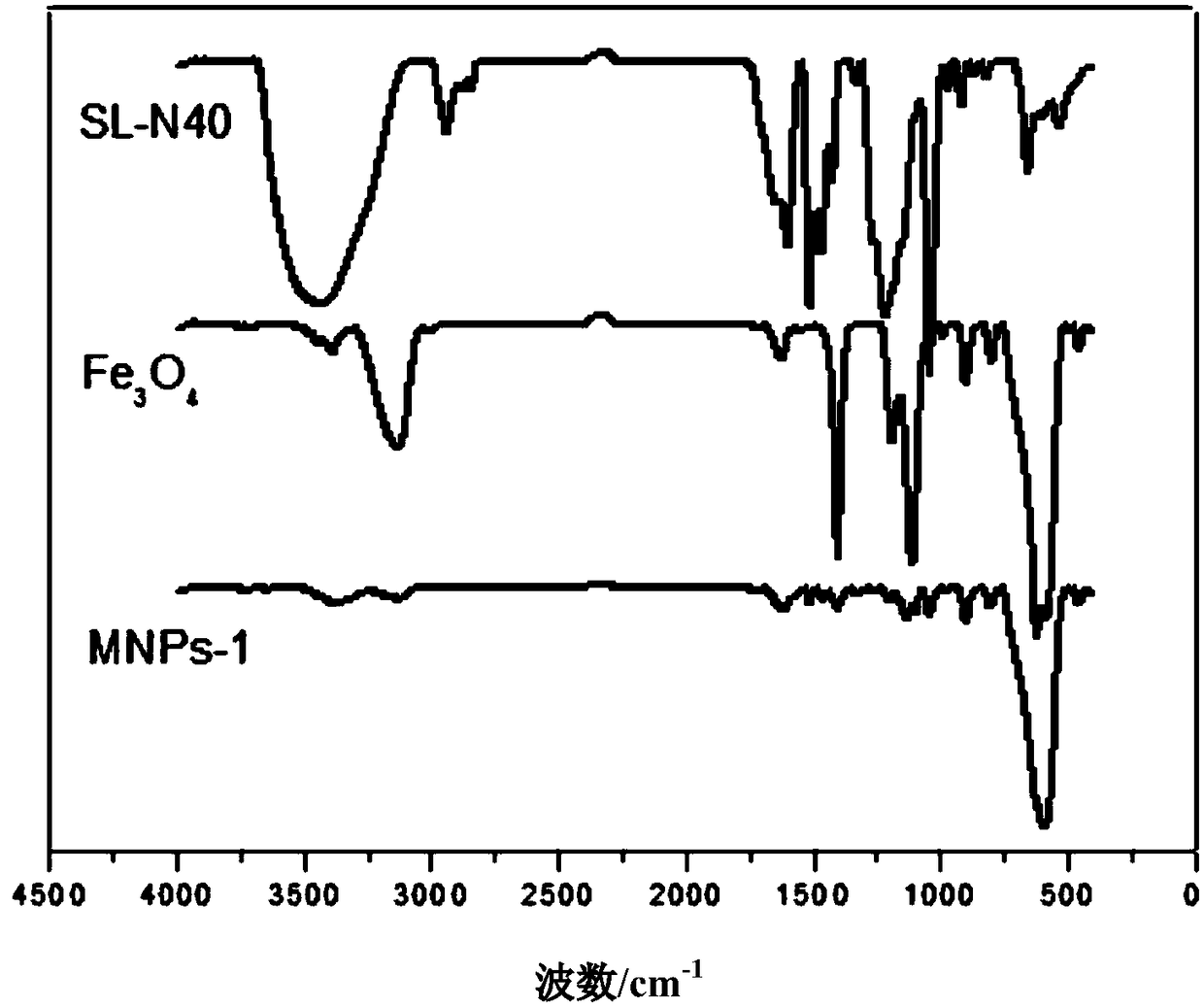

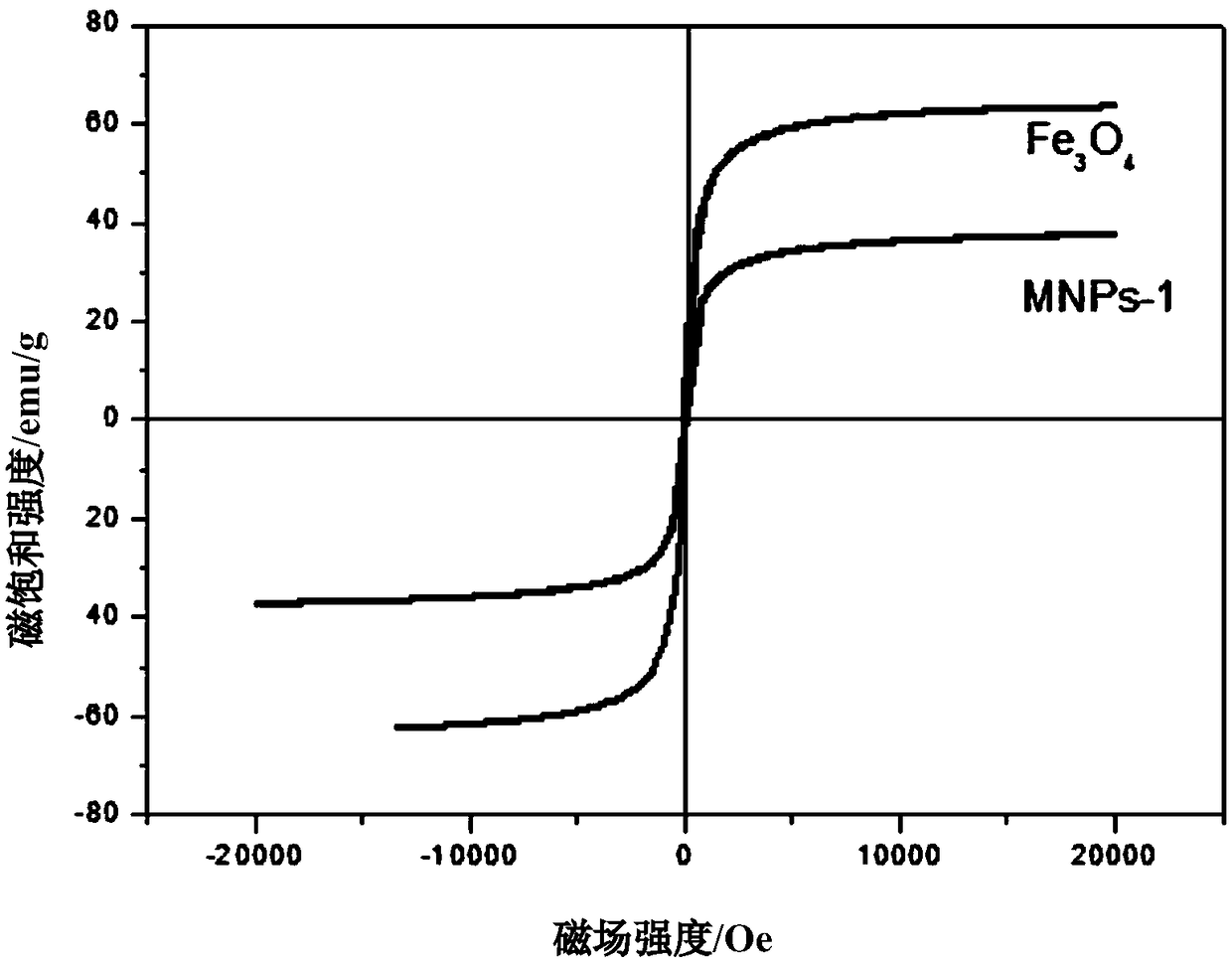

Lignin magnetic nanoparticles with pH response, preparation method thereof and application of lignin magnetic nanoparticles in cellulase recycling

InactiveCN109485872AOvercoming low productivityAchieve efficient recyclingGlycosylasesChemistryLignosulfonates

The invention belongs to the technical field of cellulase recycling and discloses lignin magnetic nanoparticles with pH response, a preparation method thereof and application of the lignin magnetic nanoparticles in cellulase recycling. The preparation method includes the steps of (1) subjecting a lignosulfonate and a quaternization reagent to reaction to obtain a lignin derivative with pH response; (2) subjecting the lignin derivative with pH response, a ferric salt and a ferrous salt to chemical co-precipitating reaction in the presence of a precipitating agent to obtain lignin magnetic nanoparticles with pH response. The invention also provides lignin magnetic nanoparticles with pH response prepared via the preparation method, and application of the lignin magnetic nanoparticles with pHresponse in cellulase recycling. The lignin magnetic nanoparticles with pH response are efficient in adsorbing and fixing cellulase and desorbing the cellulase by simple pH adjustment so as to efficiently recycle the cellulase; the recycled cellulase features high recycle rate and high activity and is reusable.

Owner:SOUTH CHINA UNIV OF TECH

Nanometer-graphene-modified blue-green alga based composite bio-plastic and preparing method thereof

InactiveCN106398142AEasy to stretchImprove barrier propertiesMicroorganism based processesFermentationBiotechnologyFiber

Nanometer-graphene-modified blue-green alga based composite bio-plastic is disclosed. The bio-plastic includes, by weight, 130-135 parts of blue-green algae, 9-10 parts of lactobacillus delbrueckii, 7-8 parts of pycnoporus sanguineus spore liquid, 16-17 parts of lactose, 9-10 parts of nanometer graphene, 10-11 parts of konjac glucomannan, 50-55 parts of pearl fibers, 56-57 parts of bamboo fibers, 24-25 parts of shell powder, 8-9 parts of vinyl methoxy silane, 7-8 parts of polyvinyl alcohol and a proper amount of water. The pearl fibers, the bamboo fibers and the shell powder in cooperation with a blue-green alga fermentation deep-processing product are adopted to prepare the bio-plastic under actions of a crosslinking agent that is the vinyl methoxy silane. The bio-plastic has biodegradability and has characteristics of high toughness and good tensile strength. The added nanometer graphene has an effect of enhancing a barrier property of the bio-plastic.

Owner:TONGLING FOUNDER PLASTICS TECH

Superionic conductor type multifunctional catalytic material as well as preparation method and application thereof

ActiveCN109364967AThe modification method is simpleThe synthesis method is simplePhysical/chemical process catalystsOrganic compound preparationHost materialHigh activity

The invention discloses a superionic conductor type multifunctional catalytic material which comprises an NASICON (Sodium Super Ionic Conductor) type Me(1-x)Ti2(PO4)3-x(SO4)x catalytic host material and a V metallic oxide. The multifunctional catalytic material comprises the following components in percentage by mass: 85-99.5% of Me(1-x)Ti2(PO4)3-x(SO4)x and 0.5-15% of V2O5, wherein Me in the material Me(1-x)Ti2(PO4)3-x(SO4)x is one of H, Cu and Ni or a mixture of Cu and Ni, and x is equal to 0.5-1. The superionic conductor type multifunctional catalytic material disclosed by the invention hasthe advantages of high activity, excellent selectivity, low cost and low toxicity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

High-salt wastewater treatment method

PendingCN110921744AEvenly heatedIncrease temperatureWater/sewage treatment by heatingCondensed waterEnergy source

The invention discloses a high-salt wastewater treatment method. Raw material liquid is subjected to n-stage continuous evaporation and concentration to generate condensed water and crystalline salt is separated in an n-th stage in a saturated manner, in the first-stage evaporation and concentration, a heater is used for heating feed liquid to 80-100 DEG C, in the second-stage evaporation and concentration, the high temperature of the fed feed liquid is used for further evaporation and concentration, in an mth-stage evaporation and concentration, heat generated by the phase change of water vapor generated in an (m-2)th-stage evaporation and concentration process is used as a heat source for main heating, the evaporated and concentrated feed liquid flows into an (m-1)th stage from the (m-2)th stage, condensate water generated by phase change of water vapor in the evaporation and concentration processes from the third stage to an nth stage is discharged as produced water, water vapor generated in the evaporation and concentration processes of an (n-1)th stage and the nth stage is discharged, m is larger than or equal to 3 and smaller than or equal to n, and n is larger than or equalto 6 and smaller than or equal to 20. The raw material liquid is preheated, so that the time for heating the feed liquid in the first stage to a set temperature is shortened, the feed liquid in the mth stage is heated by the water vapor generated in the (m-2)th stage evaporation and concentration process, and the waste of energy sources is avoided.

Owner:CHENGDU EN SHAIN TECH INC

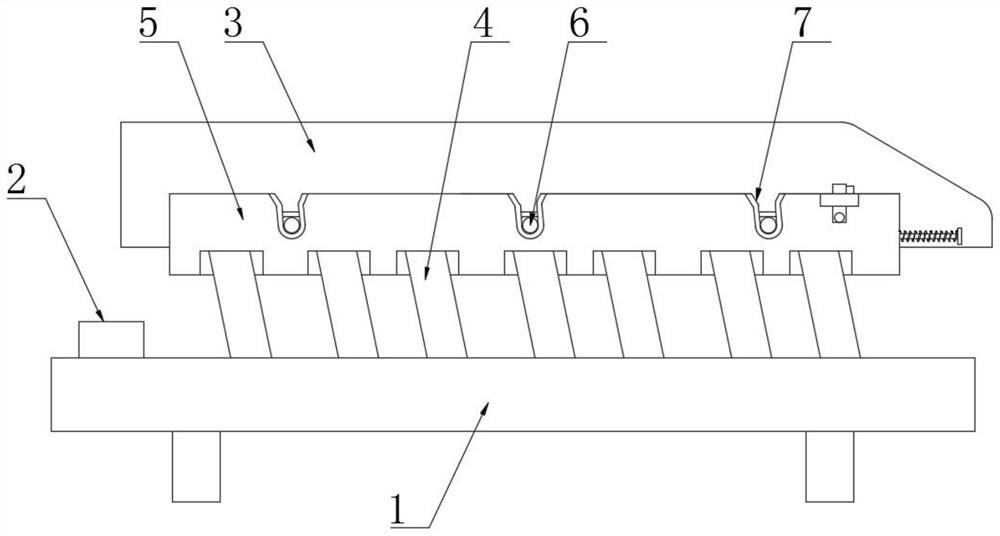

Formwork fixing device with adjustable angle and usage method

ActiveCN111364753AEasy to operateImprove installation efficiencyAuxillary members of forms/shuttering/falseworksForming/stuttering elementsControl theoryBlind hole

The invention discloses a formwork fixing device with an adjustable angle and a usage method, and belongs to the technical field of building formwork construction. An angle regulator and a fixed rod are arranged, the fixed rod is inserted on the outer side of the angle regulator through a limit groove, a groove hole and a positioning pin shaft are matched, the fixed rod is pulled when an angle requires to be adjusted, the positioning pin shaft is enabled to move to the bottom of the groove hole, at the moment, a positioning structure and a positioning blind hole realize separation, and the position of the fixed rod can be adjusted; and when the fixed rod requires to rotate, the fixed rod is rotated with the positioning pin shaft as a center, when the fixed rod is rotated to a proper position, the positioning pin shaft moves to the top of the groove hole by pushing the fixed rod, at the moment, the positioning structure and the positioning blind hole can be matched to realize the function of locking the fixed rod, then the angle adjustment is completed, the operation of construction personnel is facilitated, and the installation efficiency of a formwork is improved.

Owner:CHINA MCC17 GRP

Vibration screening mechanism for nut processing

InactiveCN111871781AEasy to moveResolution timeSievingScreeningStructural engineeringMechanical engineering

The invention discloses a vibration screening mechanism for nut processing. The vibration screening mechanism comprises a fixed seat, a vibration device and a containing box, and relates to the technical field of screening. According to the vibration screening mechanism for nut processing, the containing box and a containing frame are positioned through a positioning column and a limiting device,so that the relative stability of the positions of the containing box and the containing frame is guaranteed; the position of an L-shaped bent rod can be adjusted through a pull rod, and the positionof the positioning column can be fixed through the L-shaped bent rod and the limiting device, so that the relative positions of the containing box and the containing frame can be fixed, and it is guaranteed that the position of the containing box is relatively stable during equipment operation; and meanwhile, through the manner that the position of the containing box is fixed through cooperation of a positioning device, the limiting device and the positioning column, so that separation between the containing box and the containing frame can be conveniently achieved, the position of the containing box can be directly moved, and nuts can be conveniently moved.

Owner:合肥金果缘视觉科技有限公司

Tea-water separation type tea bin and water cup thereof

PendingCN111166134AEasy to achieve separationEasy to drinkDomestic vesselsDrinking vesselsWater drinkingTea leaf

The invention discloses a tea-water separation type tea bin. The tea bin comprises a tea bin body, and is characterized in that the tea bin body comprises an upper bin body and a lower bin body whichare detachably connected, a drinking water cavity vertically penetrating through the tea bin body is formed, the wall of the drinking water cavity and the bin walls of the upper bin body and the lowerbin body define a soaking cavity for containing tea leaves, the tea soaking cavity is provided with a water inlet hole, the bottom end of the drinking water cavity is communicated with a tea cup body, and a drinking water opening is formed in the top end of the drinking water cavity. During specific use, the upper tea bin body and the lower tea bin body are separated, tea leaves are put into thetea bin, then the upper tea bin body and the lower tea bin body are screwed down, and then the tea bin is screwed down on the cup body; finally, boiled water is poured from the drinking water opening,the cup cover is screwed down, the cup is inverted, the boiled water enters the tea bin from the water inlet, and tea making is completed. After the tea soaking is finished, the obtained tea can be directly drunk without the need of taking down the tea bin, and the tea leaves are sealed in the tea bin, so that the tea leaves cannot flow out of the water drinking opening during tea drinking.

Owner:浙江给力工贸有限公司

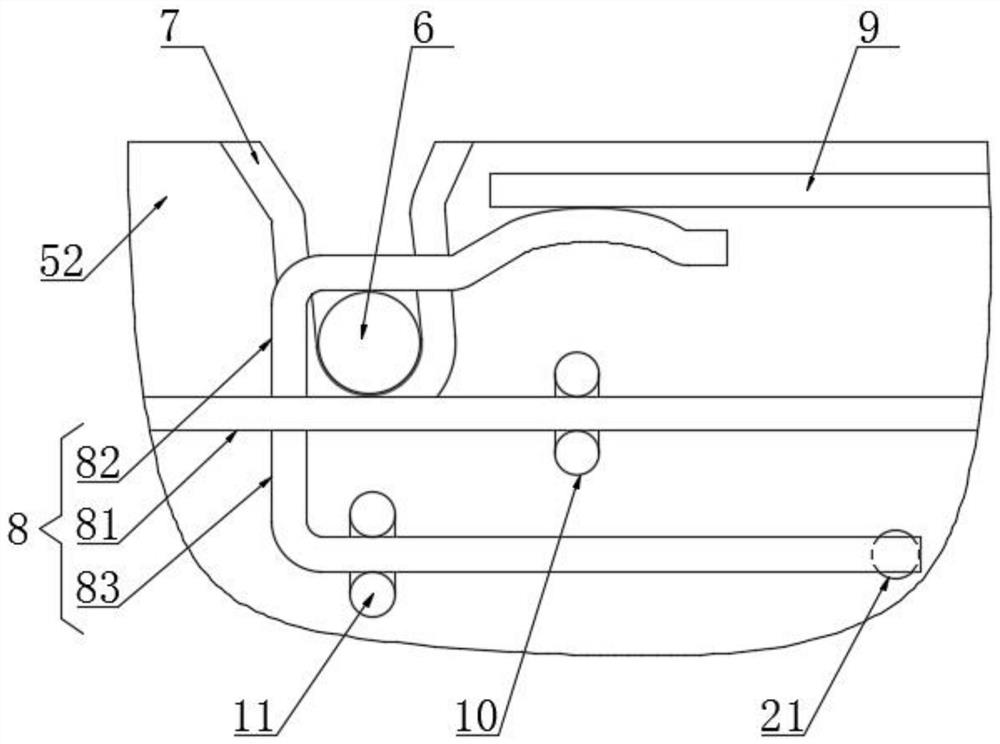

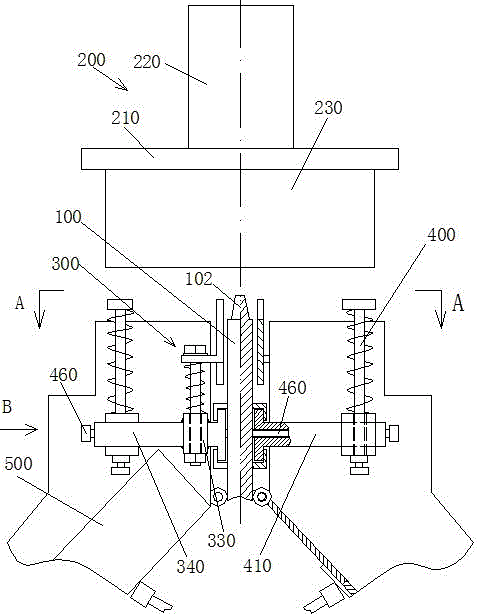

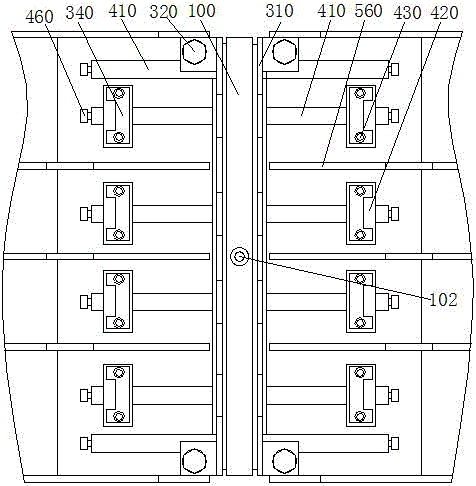

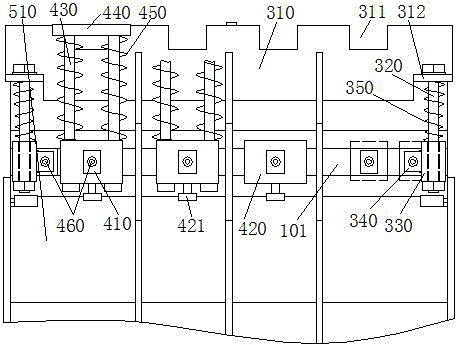

Casting separation mechanism and separation method

The invention relates to a casting separation mechanism and a separation method. The casting separation mechanism comprises a groove plate respectively provided with longitudinal chutes in two sides; a liftable vibration mechanism is arranged above the groove plate; a positioning mechanism capable of elastically lifting and used for positioning castings is arranged at the upper part of the groove plate, and is driven to lift by a vibration mechanism; waste fixing devices capable of elastically lifting are spaced on the chute of the groove plate, and are matched with the vibration mechanism to realize clamping of water port wastes of the castings; and blanking grooves for realizing classified collection of the water port wastes of the castings and products are respectively formed in the lower sides of two sides of the groove plate. The casting separation mechanism is simple and compact in structure, and is convenient to realize separation of the products and the wastes of the castings.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

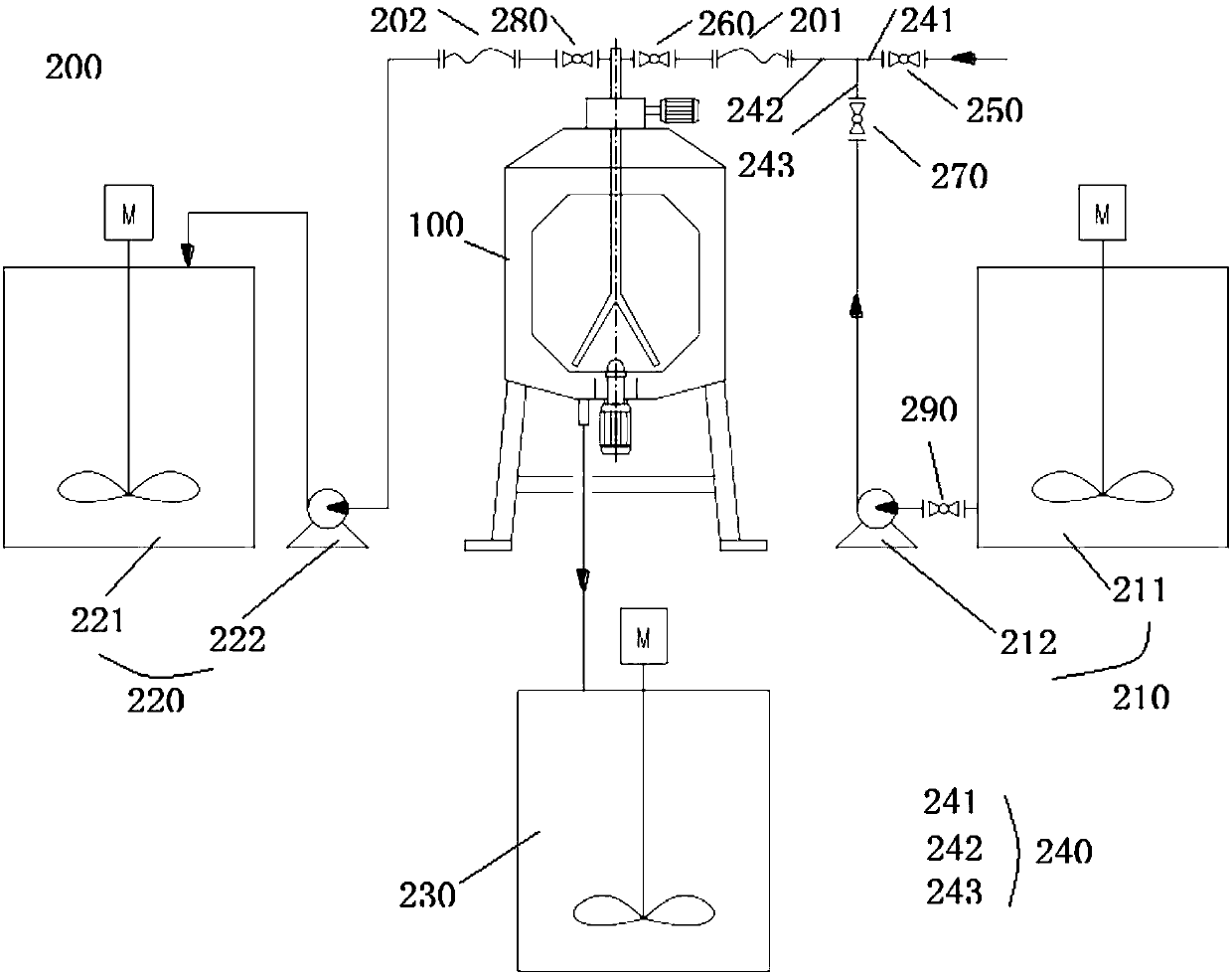

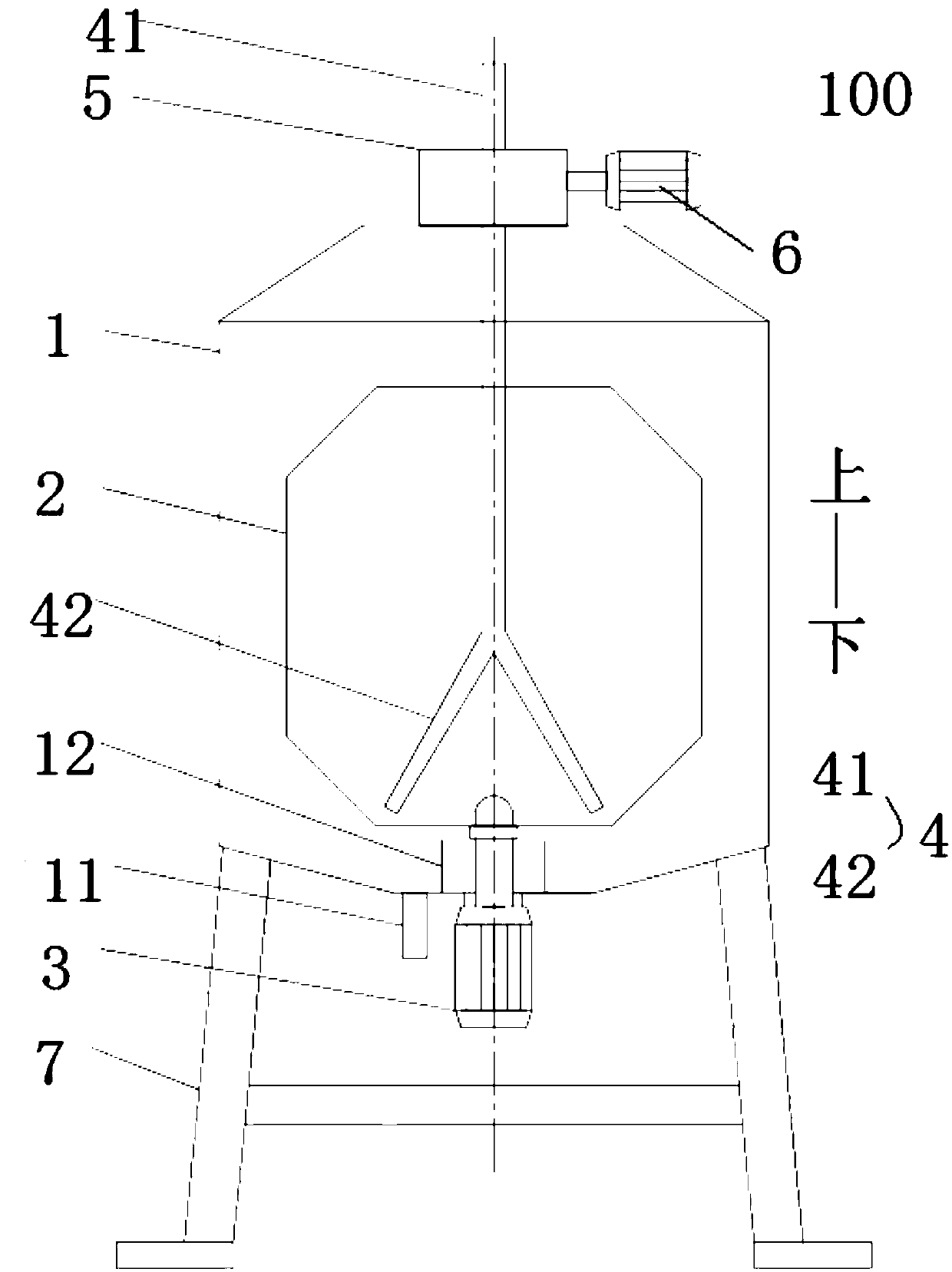

Supergravity classification process system

The invention discloses a supergravity classification process system. The supergravity classification process system comprises a supergravity classification device, a slurry feeding device, a slag flushing device, an overflow tank, a control piece and a valve body assembly; the supergravity classification device comprises an inlet and outlet pipeline and a slurry outlet; the slurry feeding deviceis connected with the inlet and outlet pipeline; the slag flushing device is connected with the inlet and outlet pipeline; the overflow tank communicates with the slurry outlet and is used for collecting slurry overflowing the supergravity classification device; the control piece comprises an integrated PLC system and is used for controlling automatic production of the supergravity classificationprocess system; the valve body assembly comprises a first port, a second port and a third port; the first port is connected with a water source; the second port communicates with the inlet and outletpipeline; the third port communicates with the slurry feeding device; and the control piece controls the first port and the third port to be connected with or disconnected from the second port separately. According to the supergravity classification process system, the connection states of the valve body assembly can be controlled by the aid of the control piece, and feeding, separation and slag flushing are realized through the supergravity classification device, so that the system is convenient to operate and high in automation degree.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for recovering scattered metal gallium in gallium nitride waste by pyrogenic process

The invention discloses a method for recovering scattered metal gallium in gallium nitride waste through a pyrogenic process, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: carrying out high-temperature calcination on the gallium nitride waste under a normal-pressure inert atmosphere protection condition, carrying out thermal decomposition on the gallium nitride waste to directly obtain a metal gallium product, converting nitrogen into N2, introducing the N2 into a protective gas for recycling, carrying out quenching cooling on the reaction product after the reaction, and recovering the metal gallium. By the adoption of the technical scheme, the metal gallium product can be obtained in one step, waste water, waste gas and waste residues are not generated in the whole process, the gallium recovery rate is high, the process is simple, cost is low, and environment friendliness is achieved; and meanwhile, efficient recovery of scattered metal gallium in the gallium nitride waste and cyclic utilization of nitrogen can be effectively achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

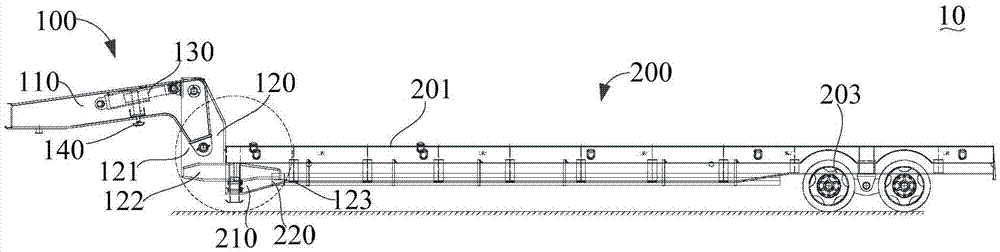

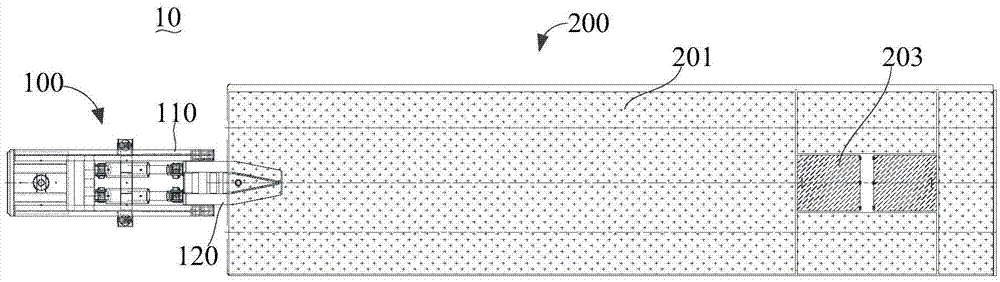

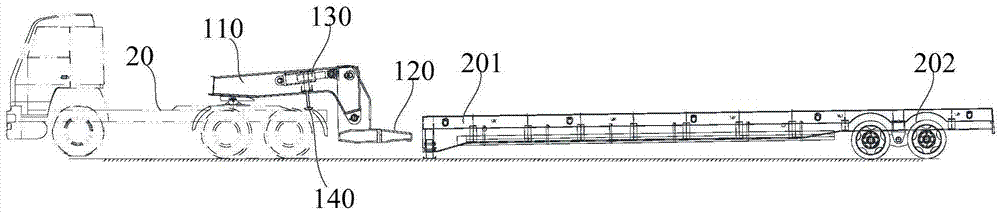

Low-flat-bed semi-trailer and traction structure and cargo carrying platform thereof

InactiveCN107200073AEasy to achieve separationAvoid wastingTractor-trailer combinationsTelescopic cylinderEngineering

The invention provides a low-bed semi-trailer, its traction structure, and a cargo platform. The traction structure includes a swing arm, a plug, and a telescopic cylinder. One end of the swing arm is used to connect with the tractor. The plug includes a connection part and an insertion part. The connecting part is rotatably connected with the other end of the swing arm, and the insertion part is used for inserting into the trailer loading platform to connect the plug with the trailer loading platform. The two ends of the telescopic cylinder are respectively connected with the connecting portion of the swing arm and the plug, so that the plug can rotate relative to the swing arm, and drive the engaging portion on the plug to clamp the trailer cargo platform or loosen from the trailer cargo platform. On the above-mentioned low-bed semi-trailer, the traction structure is detachably connected to the on-board cargo platform.

Owner:QINGDAO CIMC SPECIAL VEHICLES +1

Method for hydrocracking polyols

ActiveCN105669373AEasy to achieve separationPreparation by OH group eliminationArabitolLanthanum hydroxide

The invention relates to a method for preparing lower alcohols through catalytically hydrocracking polyols, including sorbitol, mannitol, arabitol, xylitol, butantetraol, erythritol and glycerol, by taking insoluble hydroxides as additives. The method comprises the step of catalytically hydrocracking the polyols, which serve as a raw material, in an aqueous solution at the temperature of 150 DEG C to 320 DEG C and the H2 pressure of 1MPa to 20MPa in a manner of taking one or more than two of transition metals such as platinum, ruthenium, palladium, rhodium, nickel, copper, manganese and tungsten as catalyst active ingredients and taking the insoluble hydroxides such as cobalt hydroxide, aluminum hydroxide, iron hydroxide, cerium hydroxide, lanthanum hydroxide and yttrium hydroxide as adjuvants, so as to prepare the lower alcohols such as ethylene glycol and propylene glycol. The method has the advantages that the hydrocracking of the polyols is achieved by adding the insoluble hydroxides as the adjuvants, and the insoluble hydroxides are insoluble in water and are easy in separation; and after a reaction ends, a reaction system is not required to be neutralized by using additional acids.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

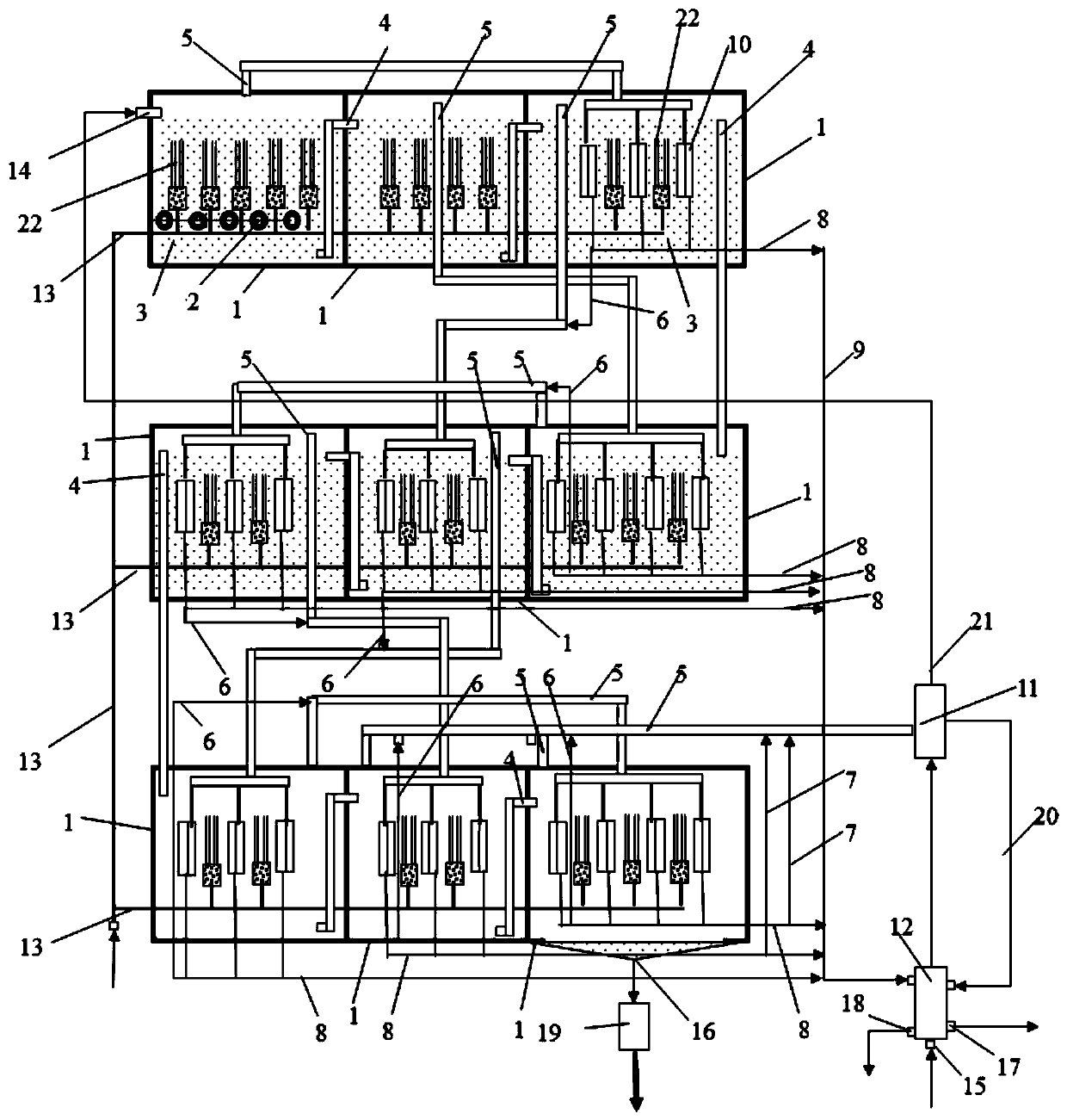

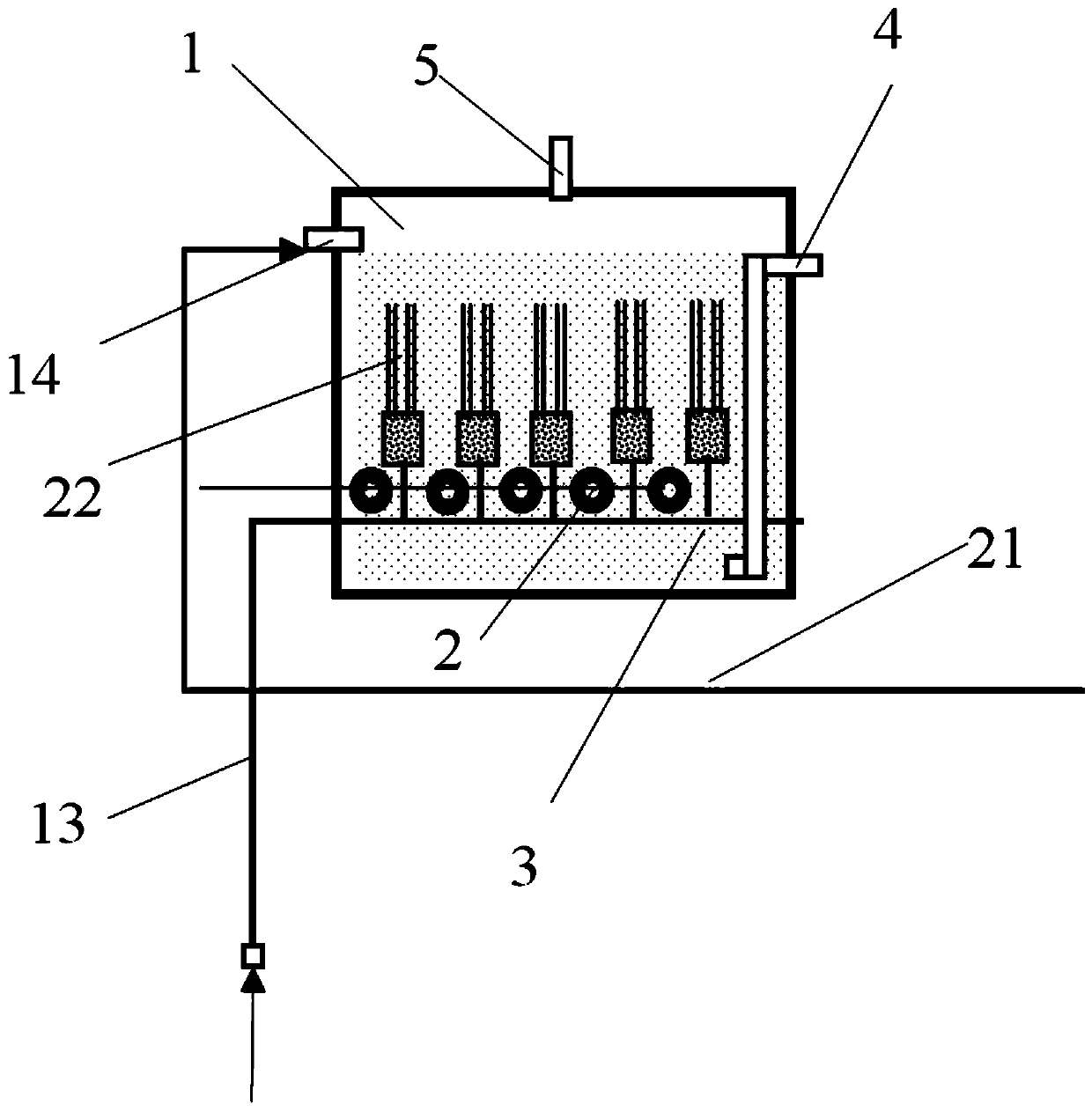

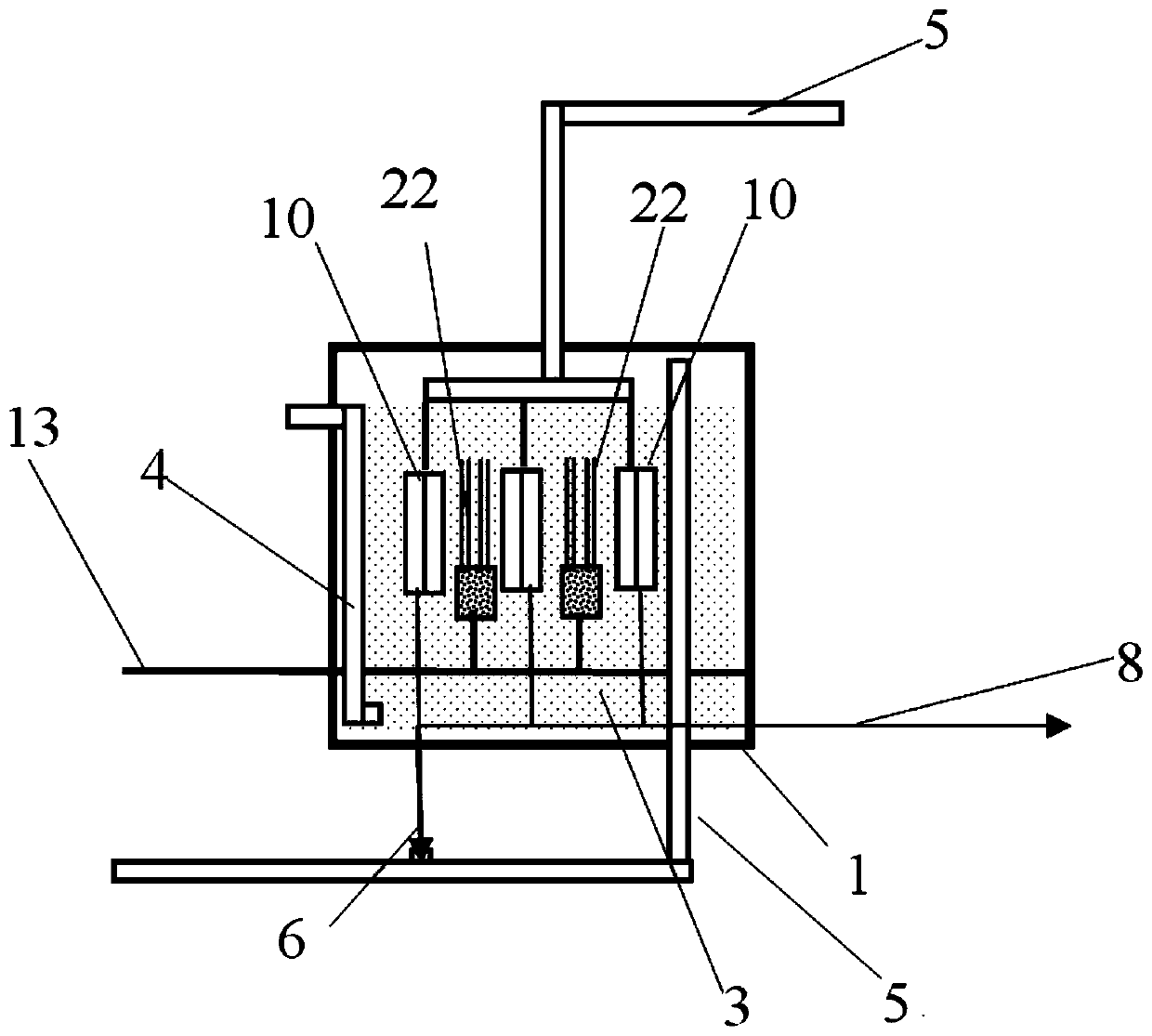

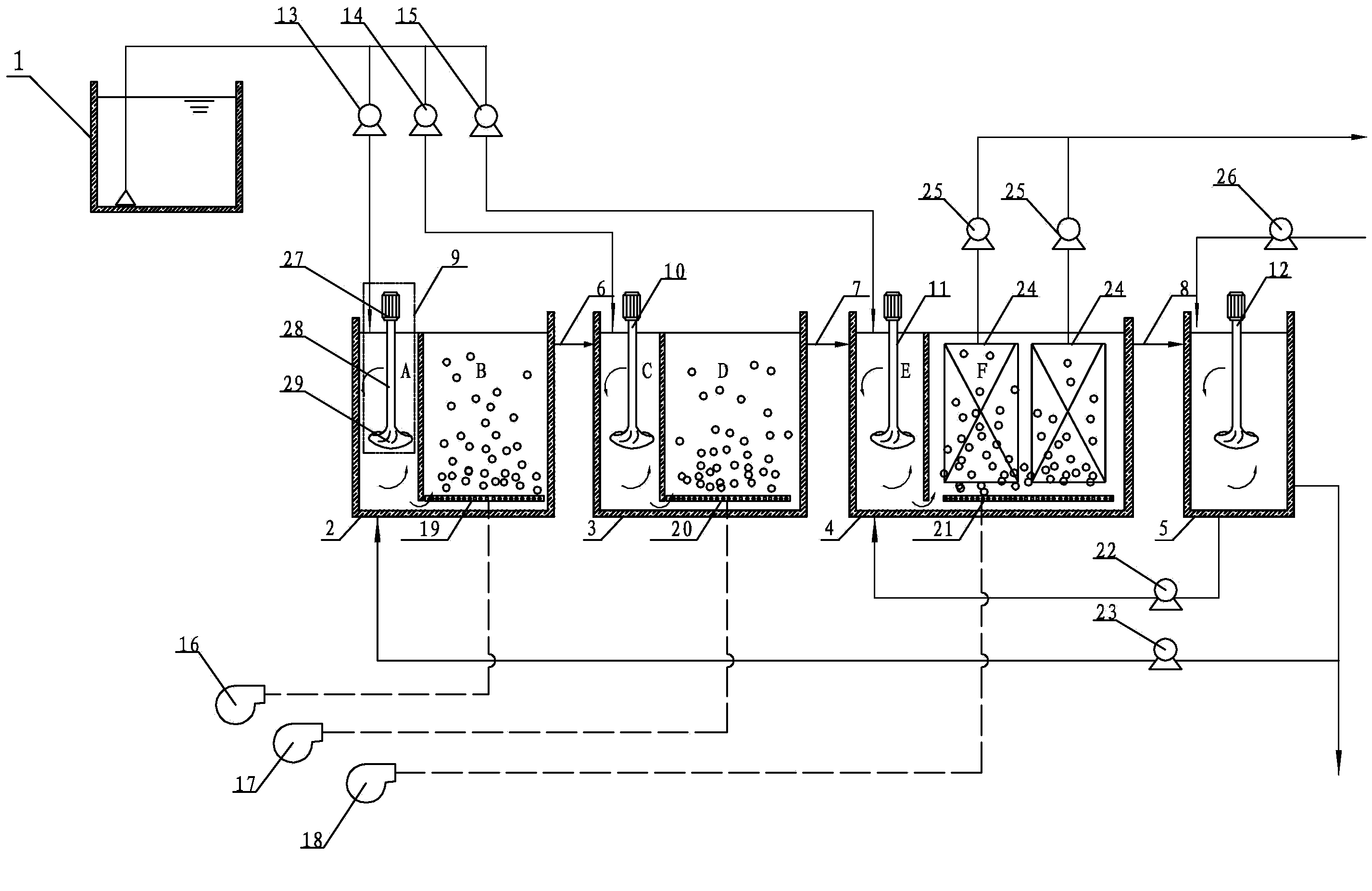

Reinforced deep-denitrifying device with multi-point water-inflow coupling fixed film

ActiveCN103641242AEfficient separationOptimize process structureTreatment with aerobic and anaerobic processesWastewaterTotal nitrogen

The invention discloses a reinforced deep-denitrifying device with a multi-point water-inflow coupling fixed film and relates to a denitrifying device, which aims at solving the problem that total nitrogen removing rate is limited by an existing stepped water-inflow A(Anoxic / O(Oxic) process, flow is complex, floor space is large, capital investment is high, deep-denitrifying control requirements are high and a control structure is complex. A flow rate regulating tank, a first-section main body structure and a second-section structure are arranged in sequence from the left to the right; a first-section mechanical stirring device and a second-section mechanical stirring device are respectively arranged in a first anoxic area and a second anoxic area, respectively; a first-section aerobic aeration area tube and a second-section aerobic area aeration tube are respectively arranged in a first aerobic area and a second aerobic area; a third-section main body structure and a rear anoxic tank are arranged in sequence from the left to the right; a third mechanical stirring device is arranged in a third anoxic zone; a rear anoxic area mechanical stirring device is arranged in the rear anoxic tank. The reinforced deep-denitrifying device disclosed by the invention is used for deep denitrifying of domestic wastewater and nitrogen-containing industrial wastewater of medium and small cities and towns.

Owner:HEILONGJIANG INST OF TECH

An intelligent crude oil dehydrating device used for oil exploitation

InactiveCN107892944AEasy to removeTemperature controlDewatering/demulsification with chemical meansTreatment with plural serial refining stagesOil separationPulp and paper industry

The invention discloses an intelligent crude oil dehydration device for petroleum development, which comprises a stirring tank, a filter chamber, a water-oil separation chamber and a tank body. One end of the stirring tank is provided with a cover door, and a control panel is installed on the cover door. The top of one side of the stirring tank is equipped with an oil inlet pipe, and the top of the stirring tank is fixed with a motor, the output end of the motor is equipped with a rotating shaft, and the bottom end of the rotating shaft passes through the top of the stirring tank and extends to the inside of the stirring tank. Stirring fan blades are evenly arranged on the rotating shaft inside the stirring tank, and the bottom end of the other side of the stirring tank is connected to the bottom end of one side of the filter chamber through the second oil guide pipe, and the bottom end of the tank body is provided with an oil outlet pipe. And the oil outlet pipe is provided with a moisture detector. The invention is equipped with a motor, a rotating shaft and a stirring fan blade, so that it is convenient to first stir the extracted crude oil, so that the internal structure is uniform, the subsequent dehydration work is convenient, and the use is convenient.

Owner:天津海润金科科技有限公司

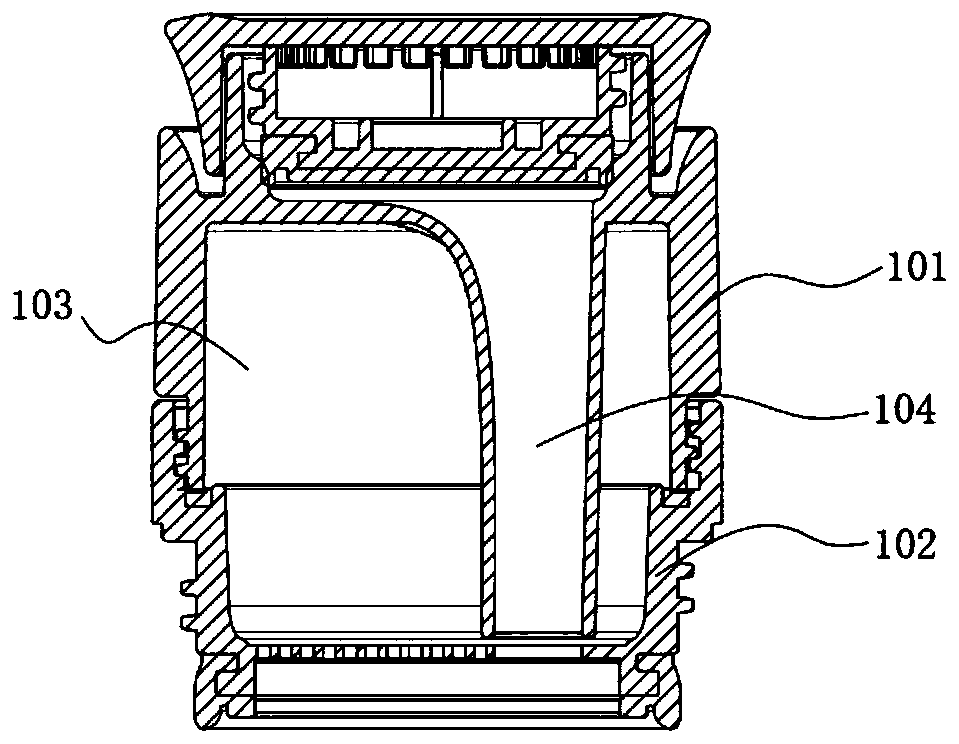

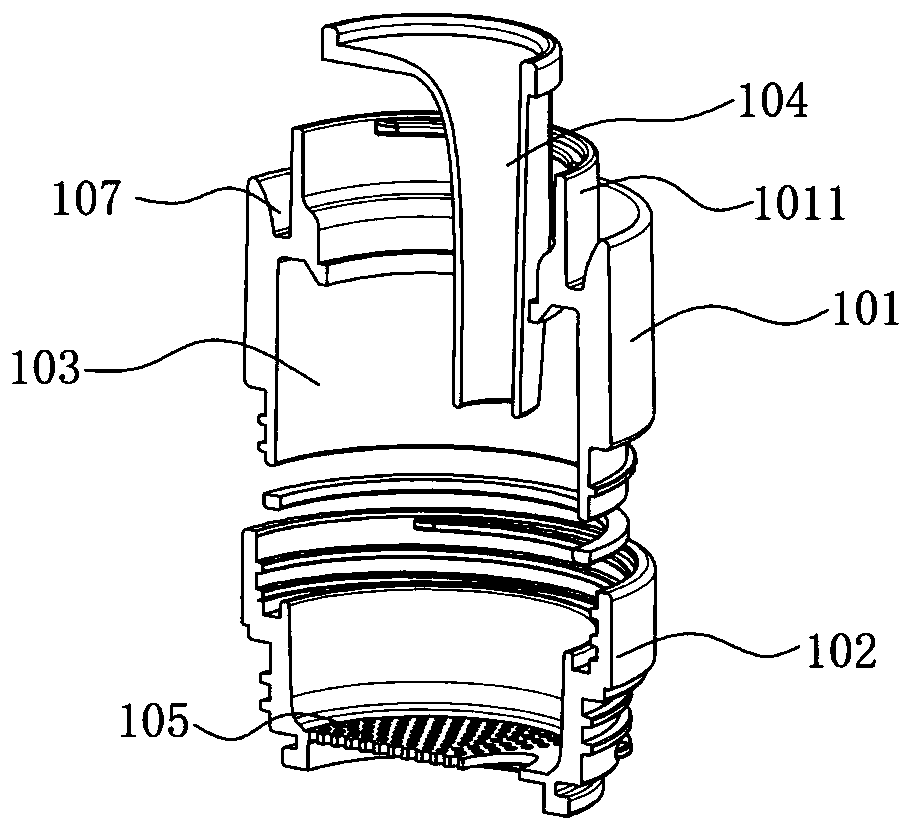

Manufacturing method of chip package and chip package

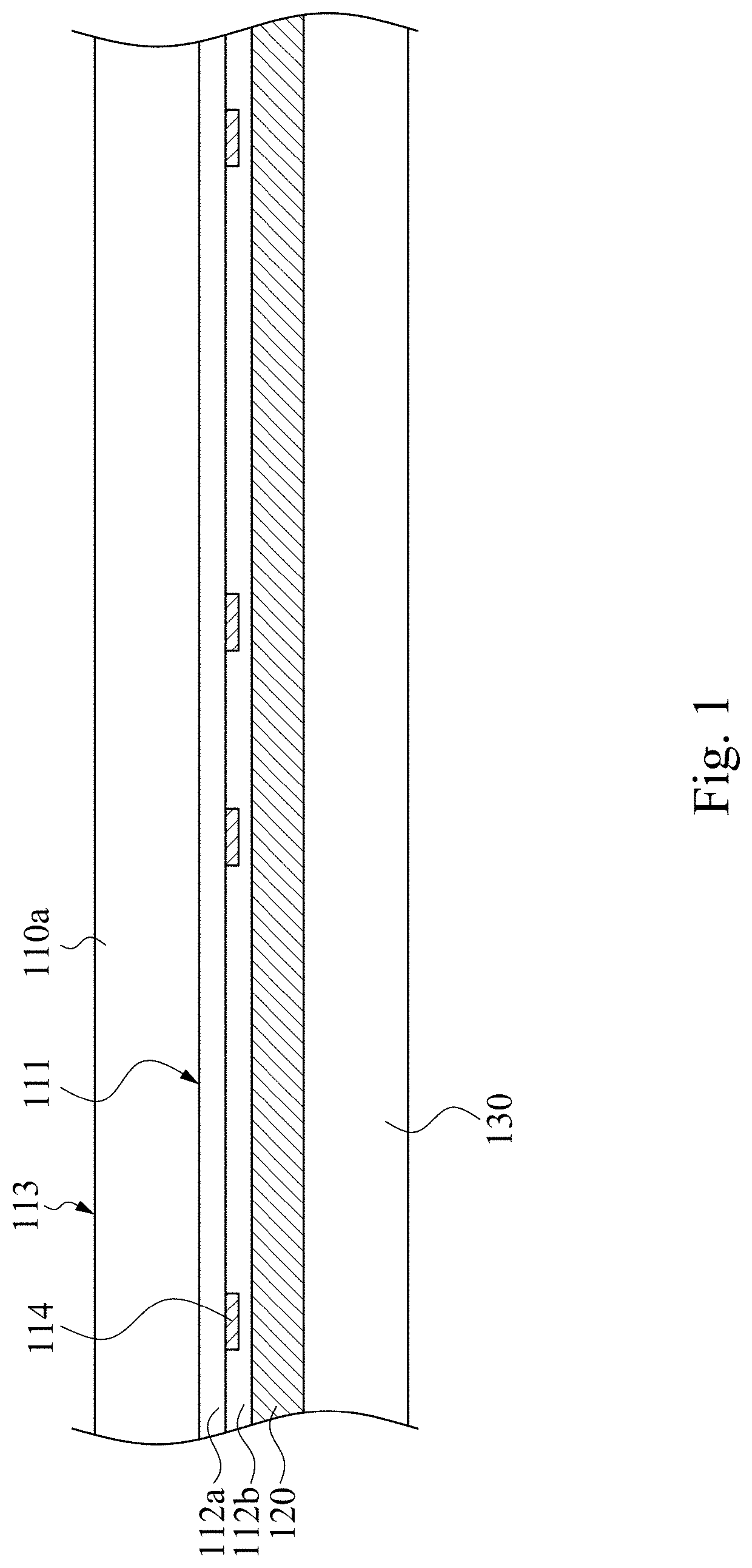

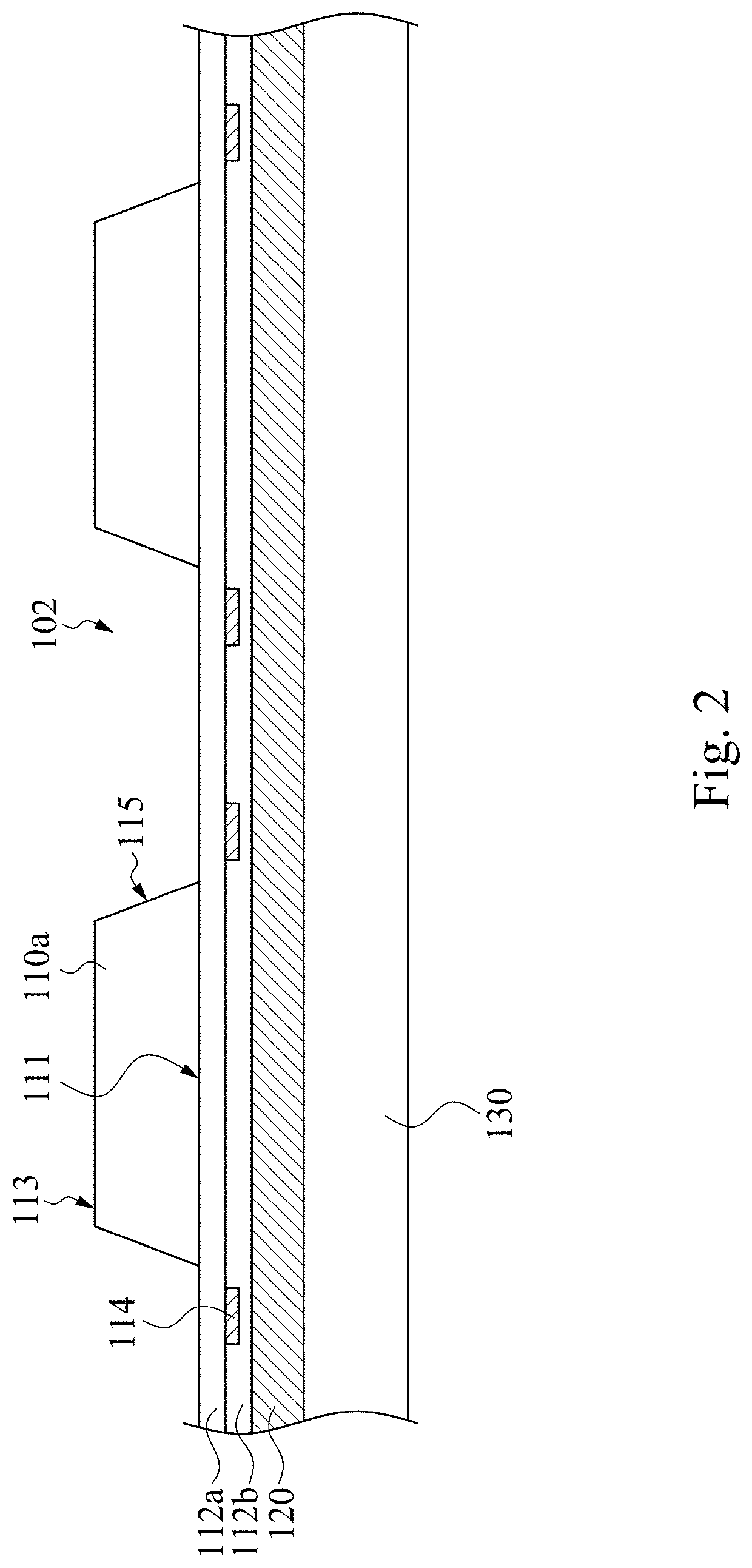

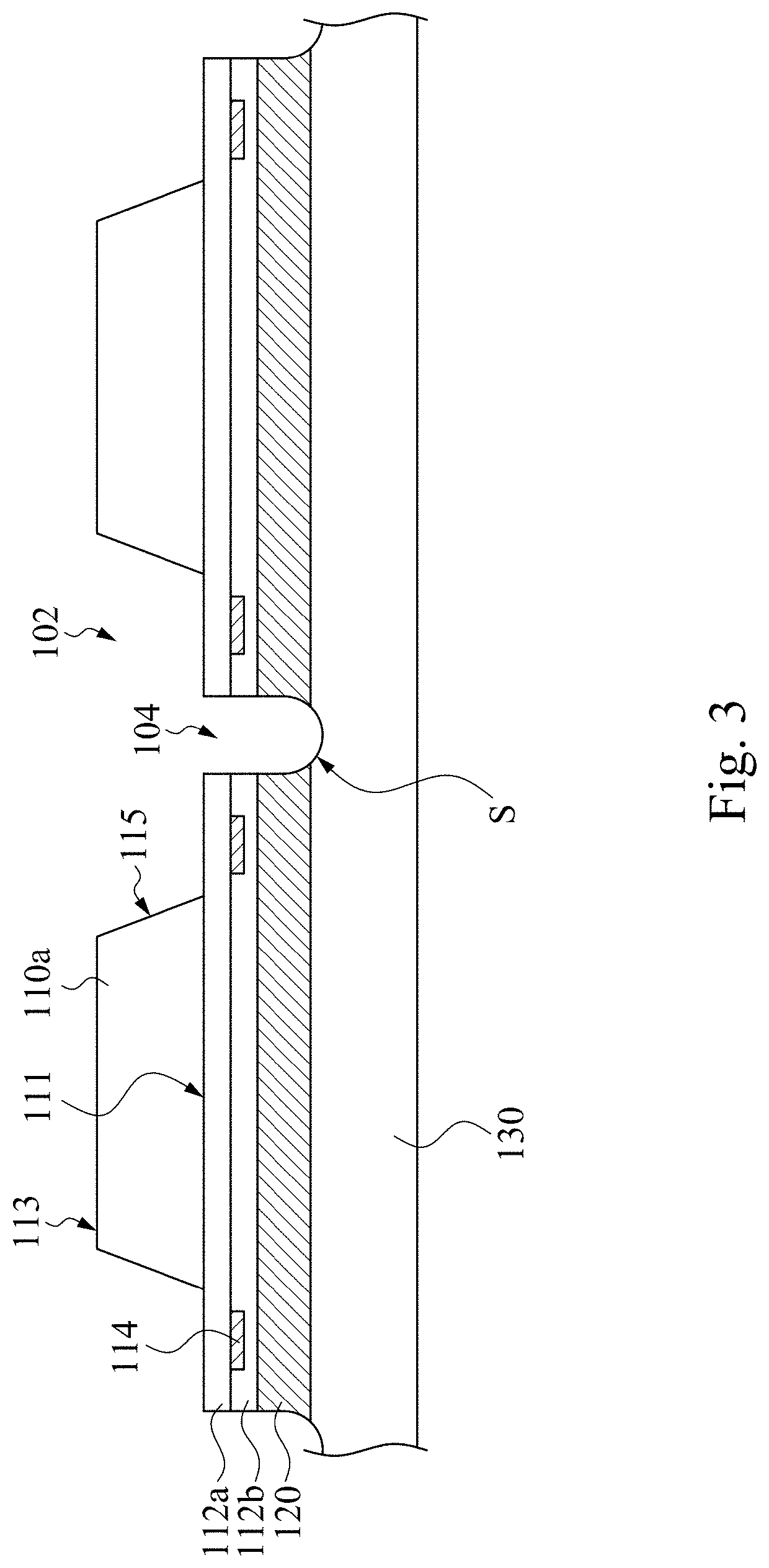

ActiveUS20200144116A1Less pollutionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesWaferingMechanical engineering

A manufacturing method of a chip package includes patterning a wafer to form a scribe trench, in which a light-transmissive function layer below the wafer is in the scribe trench, the light-transmissive function layer is between the wafer and a carrier, and a first included angle is formed between an outer wall surface and a surface of the wafer facing the light-transmissive function layer; cutting the light-transmissive function layer and the carrier along the scribe trench to form a chip package that includes a chip, the light-transmissive function layer, and the carrier; and patterning the chip to form an opening, in which the light-transmissive function layer is in the opening, a second included angle is formed between an inner wall surface of the chip and a surface of the chip facing the light-transmissive function layer, and is different from the first included angle.

Owner:XINTEC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com