Method for preparing carbon black from pyrolysis coke of waste tire through molten salt heat treatment, and product prepared by using the same

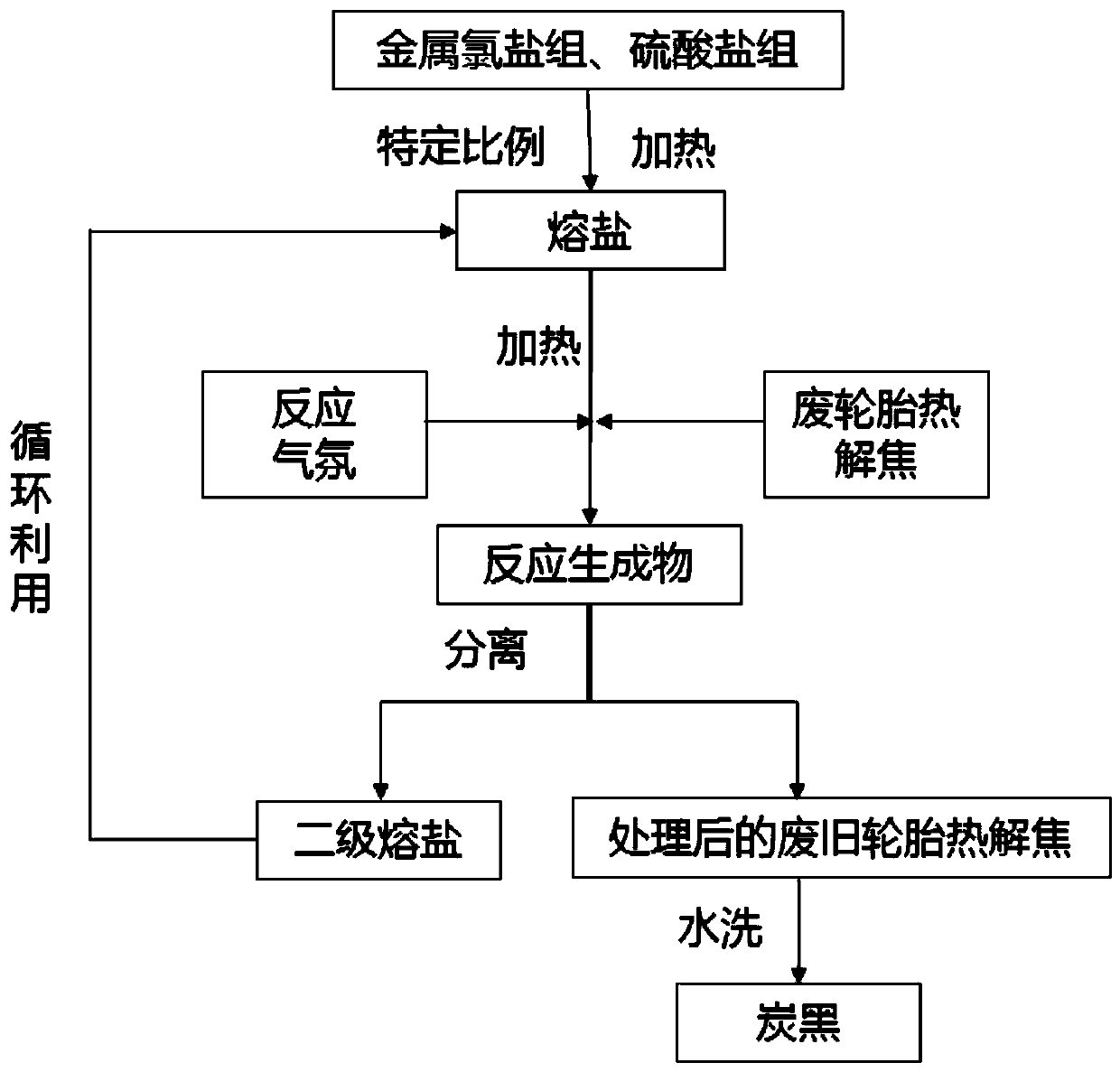

A technology of waste tires and molten salt, applied in fibrous fillers and other directions, can solve problems such as environmental pollution, inability to remove impurity components, etc., and achieve the effect of reducing pollution, facilitating disposal or resource recovery, and enhancing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (a) mixing zinc chloride, 20% sodium chloride and 20% potassium chloride with a mass fraction of 60%, then heating to 200° C. and insulated for 4 hours to obtain molten salt;

[0037] (b) Add waste tire pyrolysis coke to the molten salt, the mass ratio of waste tire pyrolysis coke to molten salt is 1:5, and the volume fraction is 1.3% hydrogen chloride, 42.7% nitrogen and 56% argon. into the reactor, and conduct molten salt heat treatment under the atmosphere, the treatment temperature is 200°C, and the treatment time is 5h;

[0038] (c) After the reaction is completed, the reaction product is separated to obtain the secondary molten salt and the treated waste tire pyrolysis coke, and the treated waste tire pyrolysis coke is washed with hot water at 30°C and then dried to obtain carbon black, At the same time, the secondary molten salt is recycled.

[0039] In Example 1, the waste tire pyrolysis coke after molten salt heat treatment has a sulfur removal rate of 50.7%, ...

Embodiment 2

[0041] (a) mixing zinc sulfate, 20% sodium sulfate and 20% potassium sulfate with a mass fraction of 60%, then heating to 600° C. and insulated for 4 hours to obtain molten salt;

[0042] (b) adding waste tire pyrolysis coke to molten salt, the mass ratio of waste tire pyrolysis coke to molten salt is 1:20, and the volume fraction is 20% water vapor and 80% nitrogen into the reactor, And carry out molten salt heat treatment under the atmosphere, the treatment temperature is 600°C, and the treatment time is 1h;

[0043] (c) After the reaction is completed, the reaction product is separated to obtain secondary molten salt and treated waste tire pyrolysis coke, and the treated waste tire pyrolysis coke is washed with hot water at 90° C. and then dried to obtain carbon black. At the same time, the secondary molten salt is recycled.

[0044] In Example 2, the waste tire pyrolysis coke after molten salt heat treatment has a sulfur removal rate of 70.3%, a calcium removal rate of 90...

Embodiment 3

[0046] (a) Mix the metal chloride salt group and the metal sulfate group with a mass ratio of 9:1, then heat to 450° C. and keep warm for 4 hours to obtain molten salt, wherein the metal chloride salt group includes zinc chloride with a mass fraction of 90% , 5% sodium chloride and 5% potassium chloride, and the metal sulfate group includes zinc sulfate, 20% sodium sulfate and 20% potassium sulfate with a mass fraction of 60%;

[0047] (b) Add waste tire pyrolysis coke to molten salt, the mass ratio of waste tire pyrolysis coke to molten salt is 1:10, feed the mixed gas of nitrogen and argon into the reactor, and carry out the process under this atmosphere Molten salt heat treatment, the treatment temperature is 450°C, and the treatment time is 2h;

[0048] (c) After the reaction is completed, the reaction product is separated to obtain the secondary molten salt and the treated waste tire pyrolysis coke, and the treated waste tire pyrolysis coke is washed with hot water at 50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com