Pimaric acid type resin acid product and method for extracting pimaric acid type resin acid product from torreya grandis aril

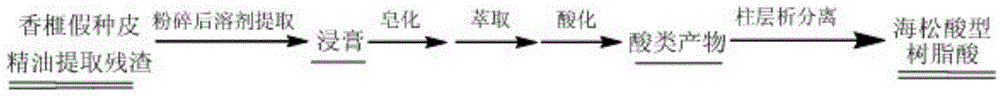

The technology of Torreya aril and resin acid is applied in the field of pimaric acid-type resin acid mixture products, which can solve the problems of interference, difficulty and obstruction in separation and purification, and achieve the effects of easy separation and purification, simple operation and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh about 200g of fresh Torreya aril, cut it into pieces and put it in a 1000mL flask, add about 300mL~400mL of distilled water and a few grains of zeolite, connect the volatile oil detector and distilled water generator, and heat the flask until there is basically no oil on the wall of the condenser tube. Turn off the heat source, cool to room temperature, and obtain 2.0mL of essential oil; for the residue in the flask, use the method of centrifugation (4000r / min, 5min) and then suction filtration to separate the aqueous solution from the solid, and the obtained solid is the essential oil Extract the residue, repeat the above process until a sufficient amount of essential oil extraction residue is obtained.

[0046] Weigh 350g of the above-mentioned essential oil extraction residue, crush it and put it into a 2000mL flask, add about 1000mL of absolute ethanol, connect the reflux condenser, reflux for 3 hours, separate the solid and liquid by suction filtration, and re...

Embodiment 2

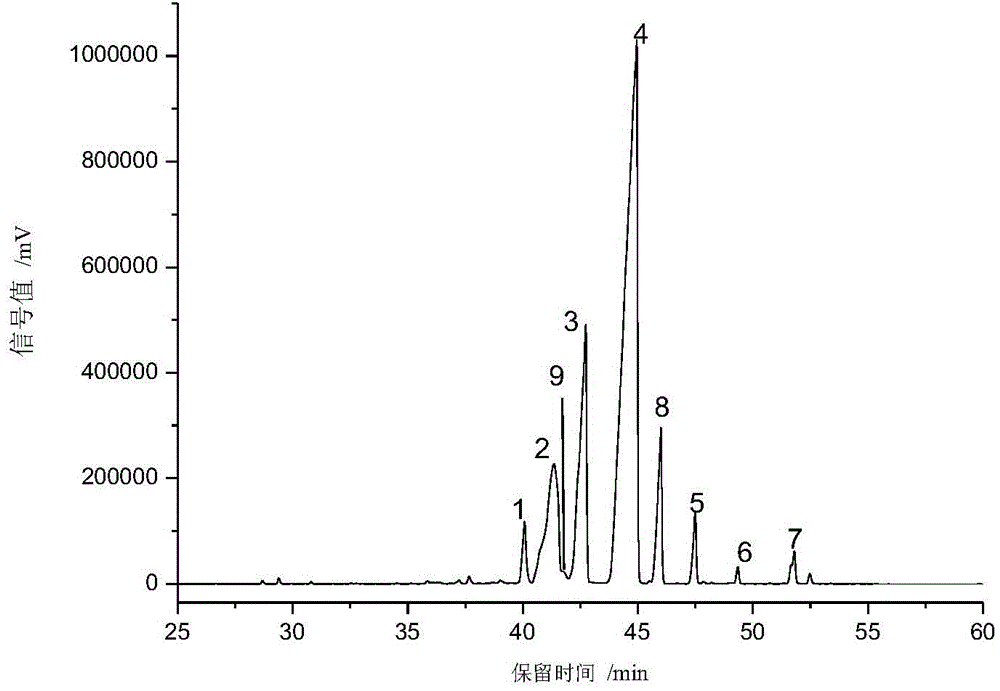

[0051]Weigh 350g of the dried residue after industrial extraction of essential oils (provided by Fengri Perfume Technology Co., Ltd., Zhuji City, Zhejiang Province), add 1000mL of absolute ethanol, perform three extractions, and share 3000mL of ethanol to obtain 96.1g of brown extract, which is analyzed by GC The results show that there are as many as 200 components contained in the extract, and the total content of resin acid is about 50%. After removing the chlorophyll and polysaccharides that do not appear in the GC analysis process, it is estimated that the actual resin acid content is about 50%. It is about 30%. Weigh 45.2g of the obtained extract, put it in a beaker, add 60mL of water, put it in a hot water bath, stir and heat to 60°C-70°C, add 100mL of KOH aqueous solution with a mass fraction of 10% for saponification for 2h, add 150mL of diethyl ether Extracted 3 times, added dropwise HCl aqueous solution with a mass fraction of 10% for acidification, and collected 23...

Embodiment 3

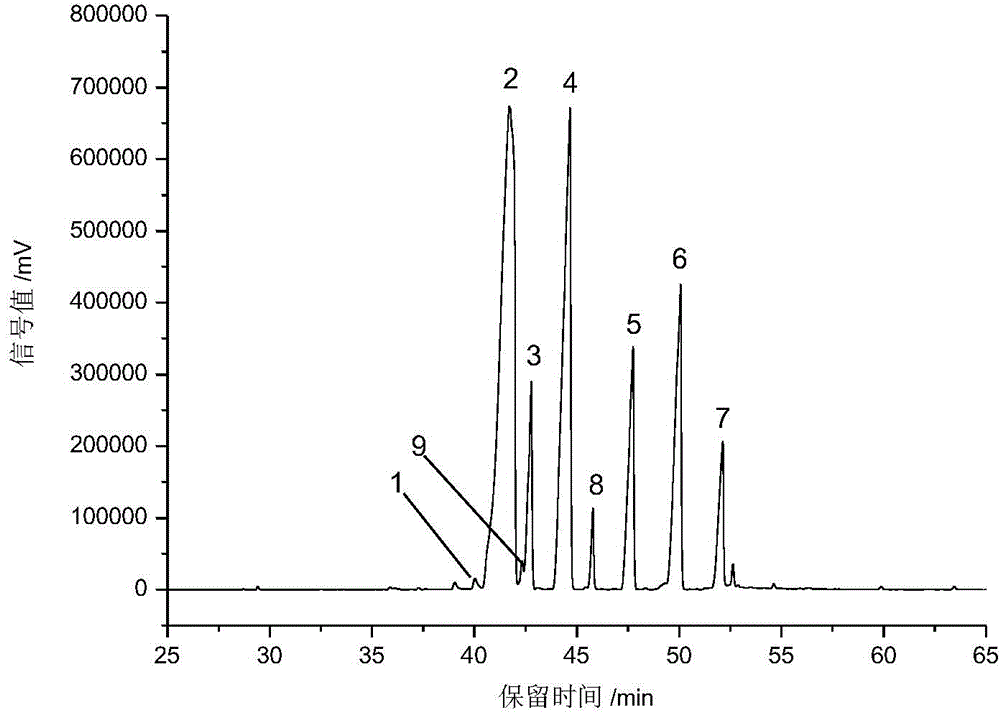

[0054] Weigh 38.0 g of the extract obtained in Example 2 and place it in a beaker, add 60 mL of water, place it in a hot water bath, stir and heat to 60°C-70°C, add 40mL of KOH aqueous solution with a mass fraction of 15% for saponification, add 150mL Diethyl ether was extracted three times, and 20% HCl aqueous solution was added dropwise for acidification, and the precipitated solid matter was collected to obtain 17.2 g of a yellow-green solid product. Weighed 3.53 g of this solid product, and carried out silica gel column chromatography separation using benzene:ethyl acetate=10:1 eluent to obtain 0.85 g of pimaric acid-type resin acid mixture product, with a total extraction rate of 3.2%. All the other operations that are not described are the same as in Example 1. The GC analysis result of the pimaric acid type resin acid mixture product shows that: the content of pimaric acid type resin acid is 89.45%, and the total resin acid content is 98.15%.

[0055] The main composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com