Waste circuit board metal recovering device based on high-frequency induction heating principle

A high-frequency induction heating and waste circuit board technology is applied in the field of waste circuit board metal recovery devices to achieve the effects of avoiding large consumption, improving working environment and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

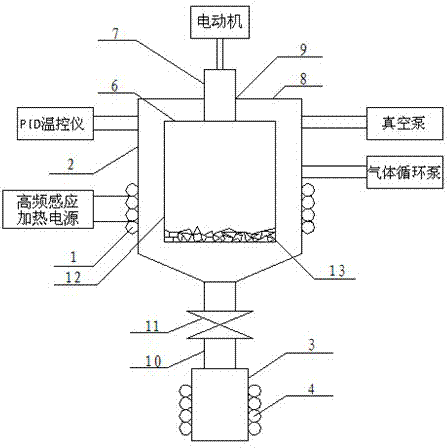

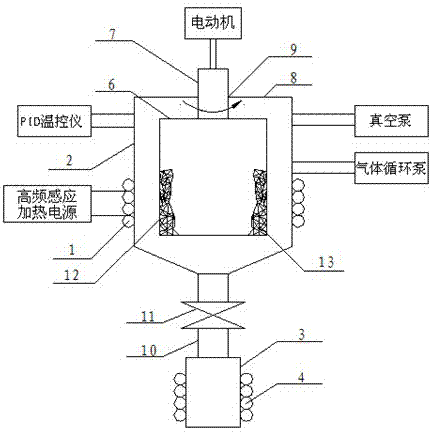

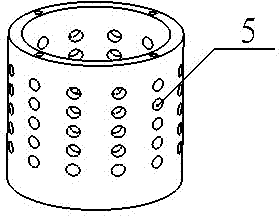

[0022] Such as Figure 1-3 As shown, in the waste circuit board metal recovery device based on high-frequency induction heating described in the embodiment of the present invention, after the motor drives the crucible (12) to rotate, the induction coil (1) is energized, and the waste circuit board fragments in the crucible (12) The metal on (13) induces heat under the action of electromagnetic induction, and clings to the inner wall of the crucible (12) in the rotating state, so that the heating effect is more significant, and the metal is in a molten state after reaching the melting point. The molten metal enters the cavity between the crucible (2) and the crucible (12) by centrifugal force, flows into the collection bottle (3) along the inner wall of the cavity, and is cooled by the cooling device (4). A waste circuit board metal recycling device based on high-frequency induction heating according to an embodiment of the present invention includes a high-frequency induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com