Bearing counting packaging machine

A packaging machine and bearing technology, applied in the field of bearing counting packaging machines, can solve problems such as affecting the efficiency of packaging machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

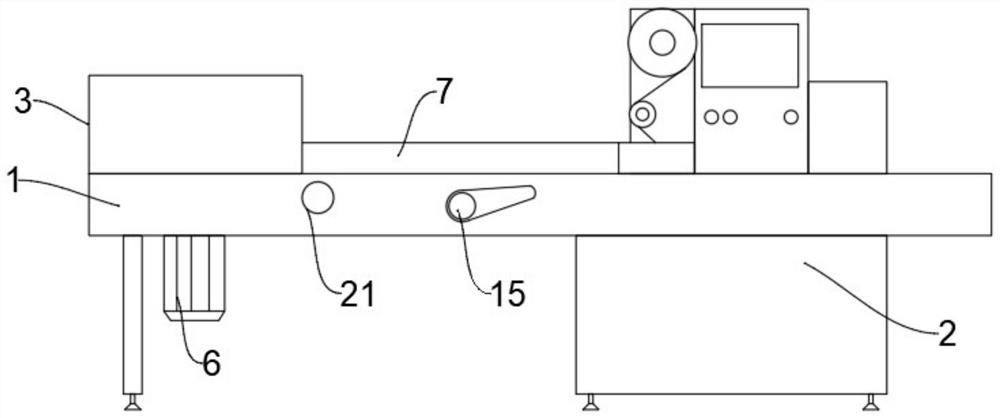

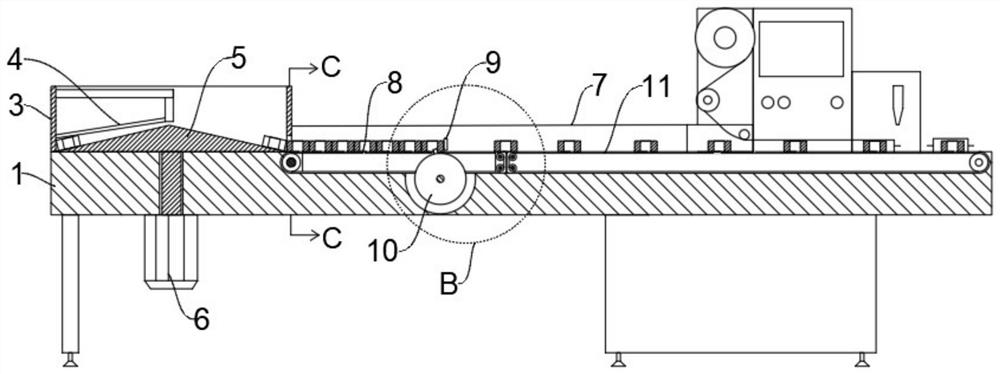

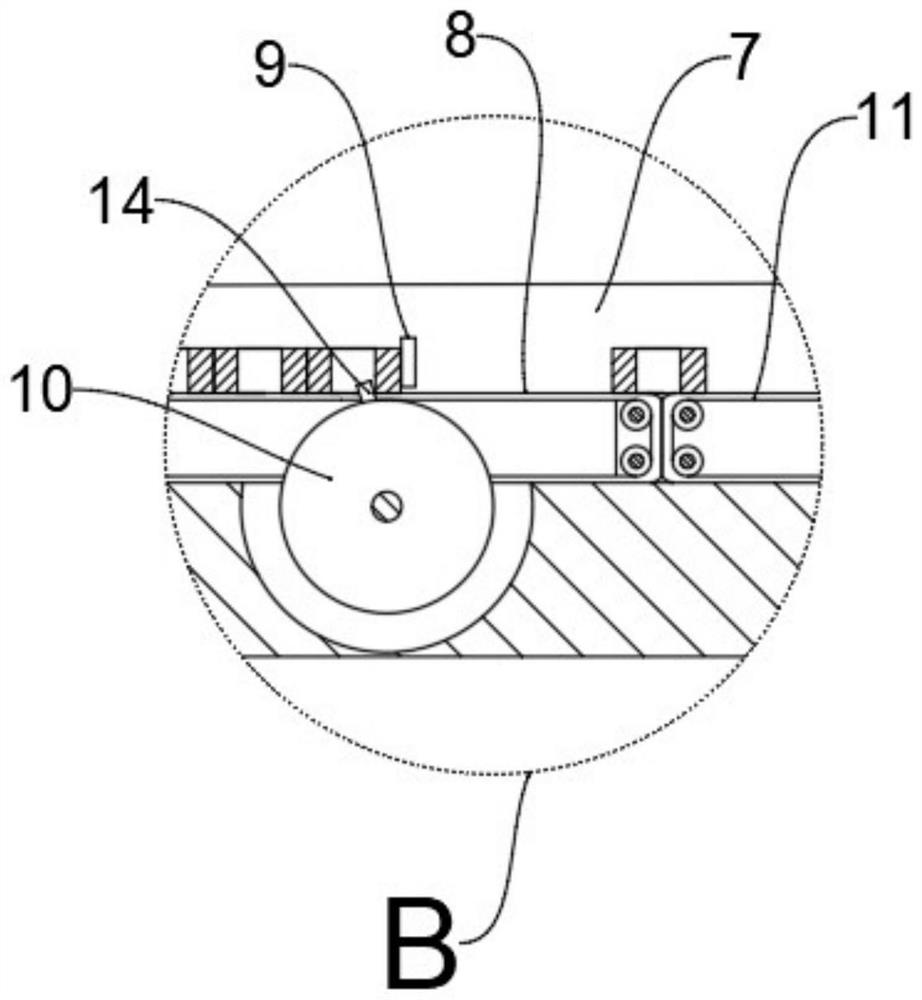

[0033] Attached below Figure 1-7 The present invention is further described with embodiment:

[0034] A bearing counting packaging machine, comprising a frame 1, a feeding mechanism, a pre-transmission device, a material distribution device, and a packaging machine body 2, the discharging mechanism is fixed on one end of the upper surface of the frame 1, and the packaging machine body 2 is fixed At the other end of the upper surface of the frame 1, the discharge port of the discharging mechanism is facing one end of the pre-transmission device, and the other end of the pre-transmission device is facing the feeding end of the packaging machine body 2. When in use, Workers can directly put the bearings into the discharge mechanism, and make a preliminary arrangement of the bearings under the action of the internal components of the discharge mechanism, and then slide the bearings from the discharge port of the discharge mechanism to the pre-transfer device. On the conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com