Formwork fixing device with adjustable angle and usage method

A formwork fixing and angle-adjusting technology, which is applied to formwork/formwork components, formwork/formwork/work frame connectors, construction components on-site preparation, etc., can solve inefficiencies, inconsistent angles, low efficiency, etc. problem, achieve the effect of improving installation efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

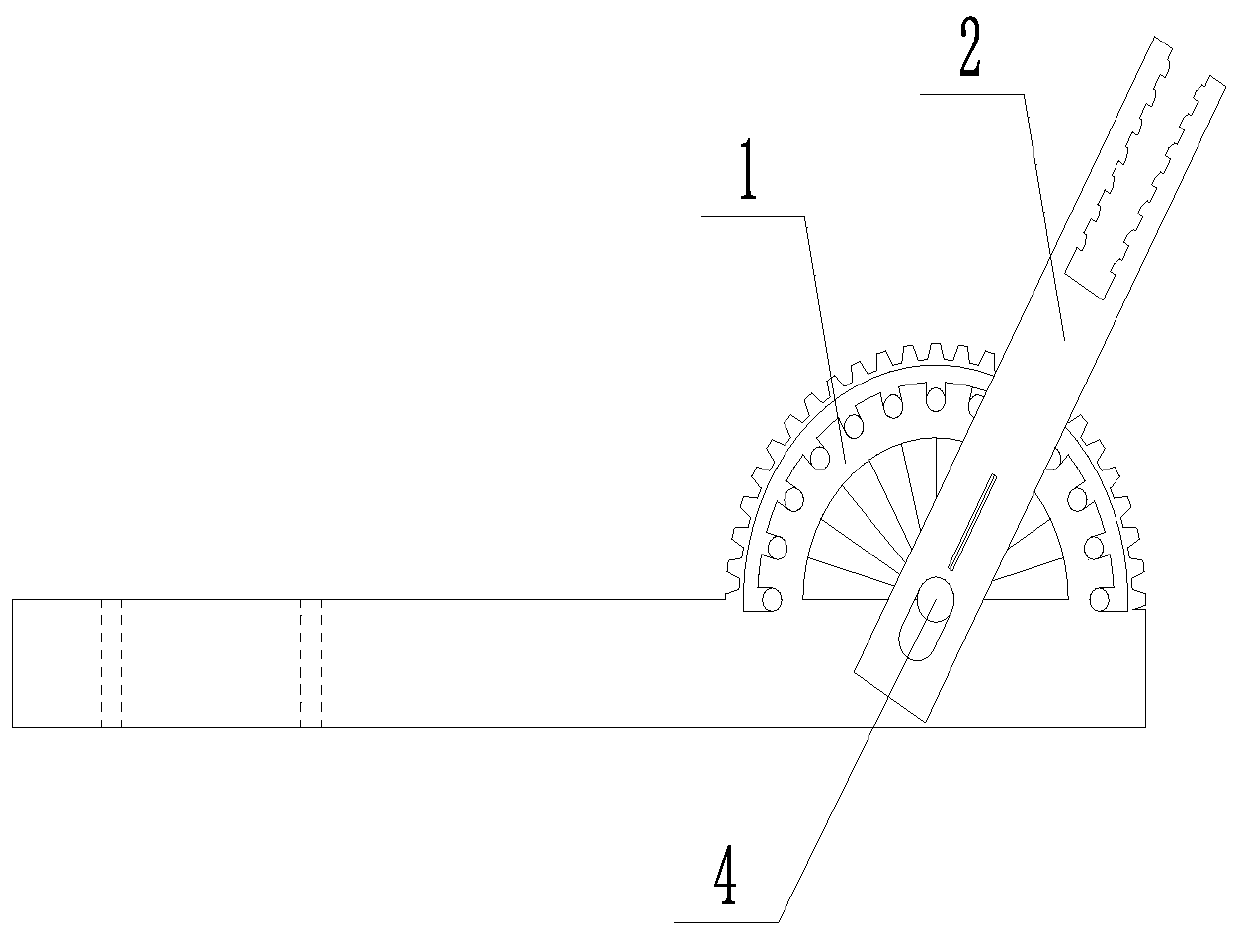

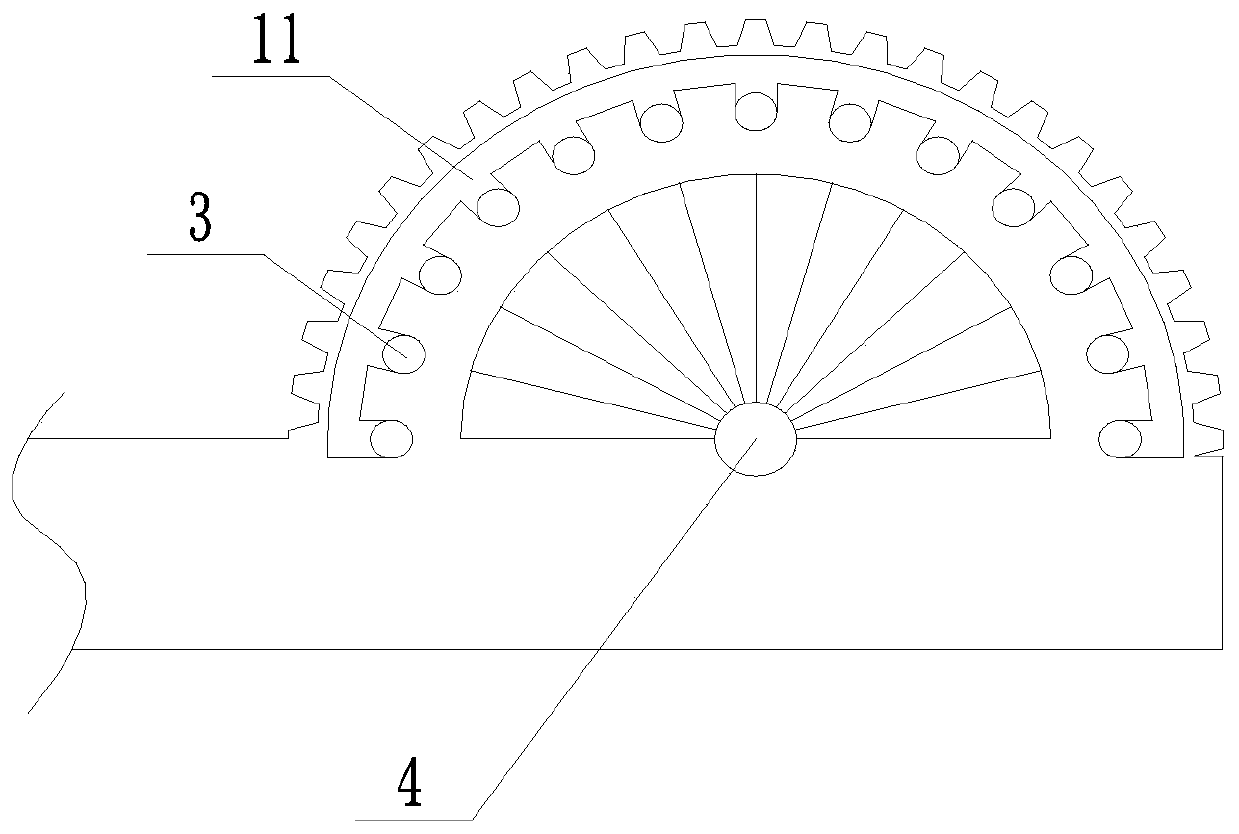

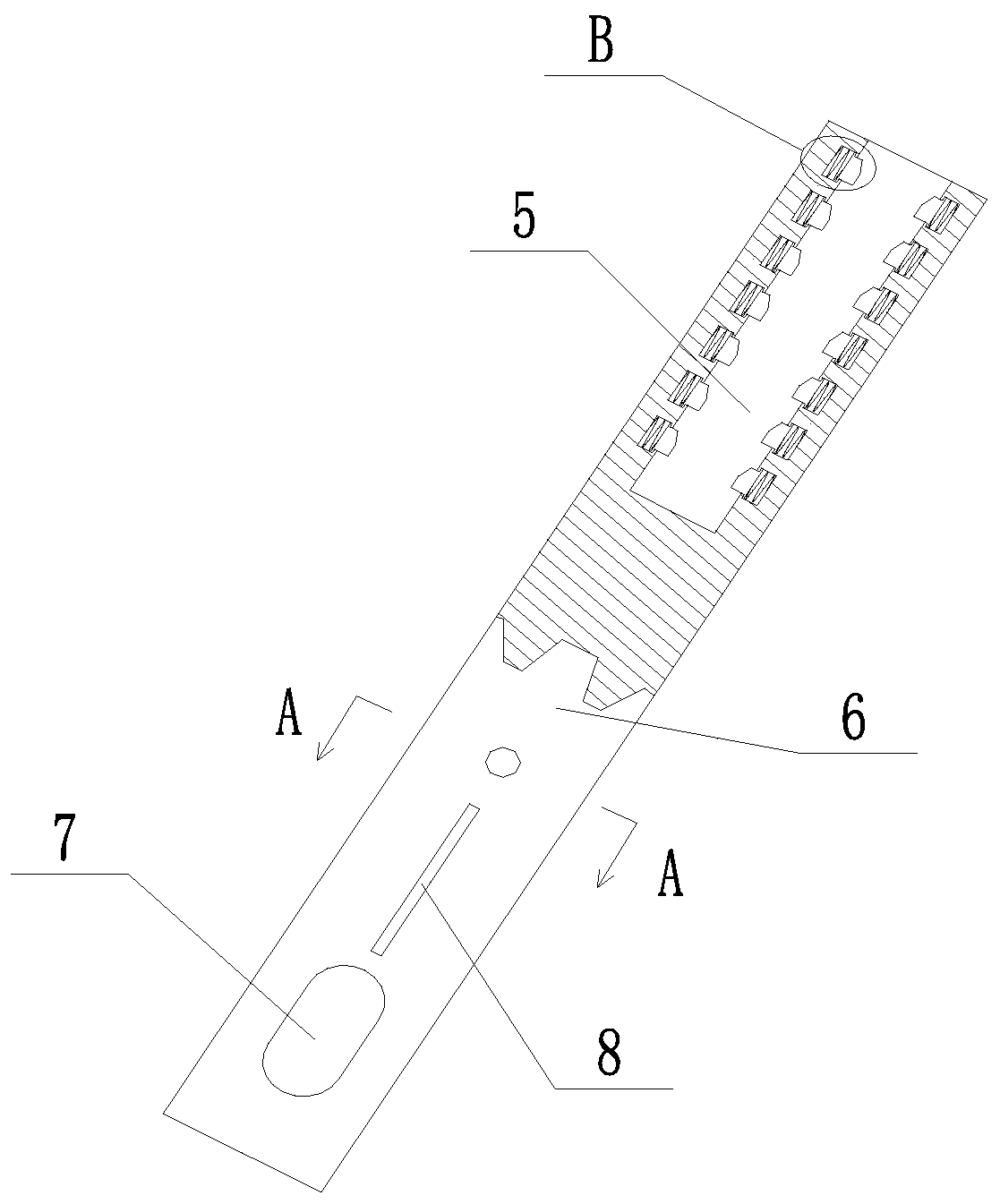

[0032] Such as Figure 1 to Figure 5 As shown, an adjustable angle template fixing device includes an angle adjuster 1 and a fixed rod 2, and the angle adjuster 1 is provided with a positioning pin 4 and a positioning blind hole 3, and several positioning blind holes 3 are provided with positioning The pin shaft 4 is evenly distributed in the center, one end of the fixed rod 2 is provided with a mounting groove 5, and the other end is provided with a limiting groove 6, the limiting groove 6 is vertically arranged with the mounting groove 5, the mounting groove 5 is used to connect the template, and the limiting groove 6 Compatible with the angle adjuster 1, the groove wall of the limit groove 6 is provided with a slotted hole 7 (the groove width of the slotted hole 7 is equal to the diameter of the positioning pin shaft 4, and the length of the slotted hole 7 is greater than the length of the positioning pin shaft 4 ), the slot hole 7 forms a sliding fit with the positioning p...

Embodiment 2

[0040] A method for using an adjustable angle template fixing device, comprising the following steps,

[0041] S1. Device installation: Fix the bolts through the installation holes on the installation base on the base layer, then insert the limit slot 6 of the fixed rod 2 on the outside of the angle adjuster 1, and pass the positioning pin shaft 4 through the limit slot 6 Fix it on the angle adjuster 1 to ensure that the positioning block 10 is compatible with the positioning blind hole 3;

[0042] S2. Pull the fixed rod 2, so that the positioning pin shaft 4 moves to the bottom along the groove wall of the slot hole 7, and at the same time, the positioning block 10 is separated from the positioning hole and moves into the track groove 11, and then the fixed rod 2 is rotated, and the fixed rod 2 uses the positioning pin The shaft 4 is the center to realize the rotation, the positioning block 10 moves in the track groove 11, observe the rotating fixed rod 2 to the desired posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com