Reinforced deep-denitrifying device with multi-point water-inflow coupling fixed film

A technology that strengthens deep and multi-point water inflow, which is applied in the field of denitrification devices, deep denitrification, and multi-point water inflow coupling fixed film enhanced deep denitrification devices. Limitation, complex control structure and other issues, to achieve the effect of improving TN removal rate, saving land occupation, and strengthening denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

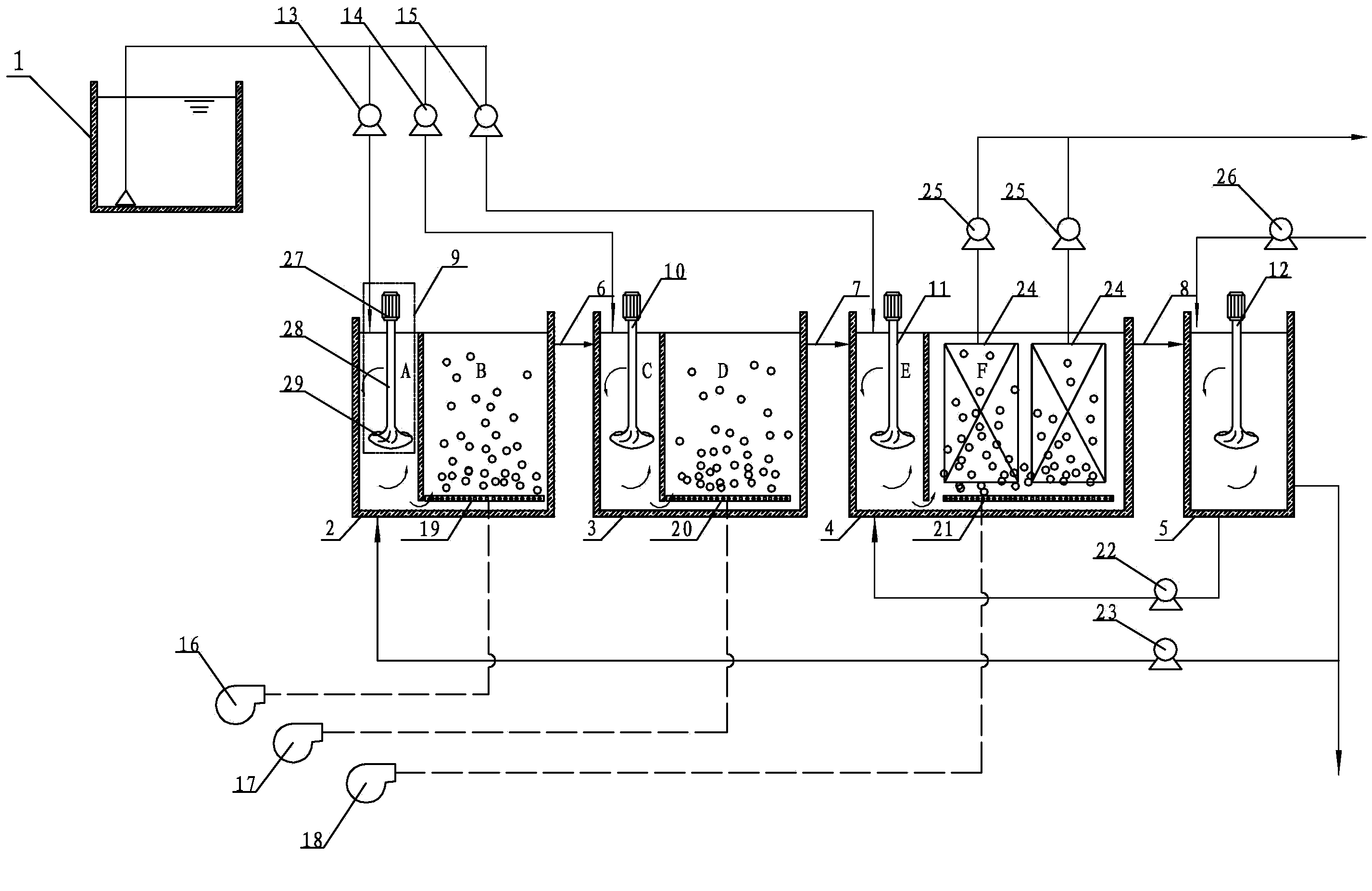

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment. This embodiment includes a flow regulating tank 1, a first-stage water inlet flow pump 13, a second-stage water inlet flow pump 14, a first-stage main body structure 2, a second-stage structure 3, and a first-stage mechanical stirring device 9 , The second section of mechanical stirring device 10, the first section of aerobic zone aeration pipe 19, the second section of aerobic zone aeration tube 20, the first section of aerobic zone gas supply device 16, the second section of aerobic zone gas supply The device 17 and the first section of the water outlet pipe 6, the flow regulating pool 1, the first section of the main structure 2 and the second section of the structure 3 are arranged in sequence from left to right, and the inside of the first section of the main structure 2 is divided into the first anoxic zone by a partition A and the first aerobic zone B, and the lower part of the first ano...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1Describe the present embodiment, the first stage mechanical stirring device 9 of the present embodiment, the second stage mechanical stirring device 10, the 3rd mechanical stirring device 11, the post anoxic zone mechanical stirring device 12 all comprise motor 27, stirring shaft 28 and The stirring paddle 29, the motor 27, the stirring shaft 28 and the stirring paddle 29 are connected sequentially from top to bottom. With such arrangement, the structure is simple and the stirring effect is good. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Describe this embodiment, the bottom end face of the partition wall in the first section of the main structure 2, the second section of the structure 3 and the third section of the main structure 4 of this embodiment is provided with a water outlet, the water outlet is a square, and the determination of the area is based on daily The maximum and minimum water inflow flow rate is guaranteed to be 0.8m / s~2.5m / s. Such setting makes the mixing of pollutants and activated sludge more complete, and facilitates the formation of plug flow mode. Other compositions and connections are the same as in the first embodiment.

[0019] Specific implementation mode four: combination figure 1 Describe this embodiment, the aeration pipe 19 of the first section of the aerobic zone, the aeration pipe 20 of the second section of the aerobic zone and the aeration pipe 21 of the third section of the aerobic zone of this embodiment are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com