Superionic conductor type multifunctional catalytic material as well as preparation method and application thereof

A multifunctional catalysis, superionic technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve the problems of methanol and methyl acetate cracking, difficult to carry out, etc., and achieves simple modification method and synthesis. Simple process and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of superionic conductor catalyst

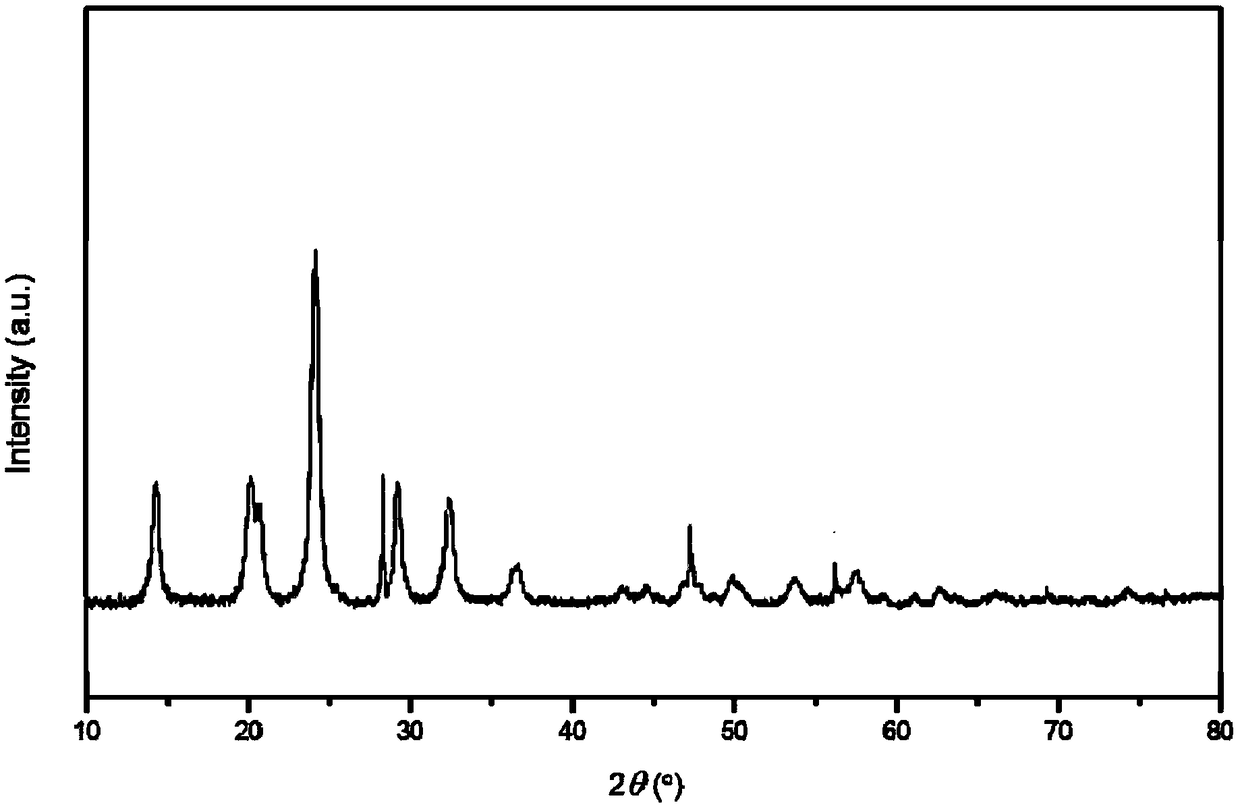

[0024] (1) NASICON type Me 1-x Ti 2 (PO 4 ) 3-x (SO 4 ) x material preparation

[0025] 9.2g titanyl sulfate-sulfuric acid hydrate (≥29%Ti(as TiO 2 ) basis, ≤17% free acid (asH 2 SO 4) was dissolved in 20 g of distilled water, then 8 g of 30% hydrogen peroxide and 6.0 g of polyethylene glycol 20000 (PEG20000) were added in sequence, and stirred evenly. Thereafter, 6.0 g of concentrated phosphoric acid with a concentration of 85% was slowly added dropwise with vigorous stirring. Afterwards, the colloidal solution was dried in a vacuum oven at 60 °C for 12 h. The dried sample is placed in a muffle furnace, heated to 600°C at a rate of 2°C / min, and roasted for 6 hours to obtain NASICON type H 0.08 Ti 2 (PO 4 ) 2.08 (SO 4 ) 0.92 Raw material powder.

[0026] (2) Preparation of V-modified NASICON catalysts

[0027] (A) Using equal volume impregnation method, the H prepared in 3g step (1) 0.08 Ti 2 (PO 4 )...

Embodiment 2

[0032] 1. Preparation of superionic conductor catalyst

[0033] (1) NASICON type Me 1-x Ti 2 (PO 4 ) 3-x (SO 4 ) x material preparation

[0034] 9.2g titanyl sulfate-sulfuric acid hydrate (≥29%Ti(as TiO 2 ) basis, ≤17% free acid (asH 2 SO 4 ) was dissolved in 15 g of distilled water, then 6 g of 30% hydrogen peroxide and 7.5 g of polyethylene glycol 20000 (PEG20000) were added in sequence, and stirred evenly. Then, 7.2 g of 85% concentrated phosphoric acid was slowly added dropwise and stirred vigorously. Afterwards, the colloidal solution was dried in a vacuum oven at 80°C for 16 h. The dried sample is placed in a muffle furnace, heated to 600°C at a rate of 4°C / min, and fired for 6 hours to obtain NASICON type H 0.5 Ti 2 (PO 4 ) 2.5 (SO 4 ) 0.5 Raw material powder.

[0035] (2) Preparation of V-modified NASICON catalysts

[0036] (A) Using equal volume impregnation method, the H prepared in 3g step (1) 0.5 Ti 2 (PO 4 ) 2.5 (SO 4 ) 0.5 The original pow...

Embodiment 3

[0041] 1. Preparation of superionic conductor catalyst

[0042] (1) NASICON type Me 1-x Ti 2 (PO 4 ) 3-x (SO 4 ) x material preparation

[0043] 9.2g titanyl sulfate-sulfuric acid hydrate (≥29%Ti(as TiO 2 ) basis, ≤17% free acid (asH 2 SO 4 ) was dissolved in 10 g of distilled water, then 7 g of 30% hydrogen peroxide, 4.85 g of nickel acetate, and 6.5 g of polyethylene glycol 20000 (PEG20000) were added in sequence, and stirred evenly. Then, 6.9 g of 85% concentrated phosphoric acid was slowly added dropwise and stirred vigorously. Afterwards, the colloid solution was dried in a vacuum oven at 70 °C for 18 h. The dried sample is placed in a muffle furnace, heated to 550°C at a rate of 3°C / min, and fired for 4 hours to obtain NASICON-type Ni 0.39 Ti 2 (PO 4 ) 2.39 (SO 4 ) 0.61 Raw material powder.

[0044] (2) Preparation of V-modified NASICON catalysts

[0045] (A) Using the equal volume impregnation method, the Ni prepared in the 3g step (1) 0.39 Ti 2 (PO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com