Salicylic acid functionalized graphene modified electrode and heavy metal detection method thereof

A salicylic acid and fossil technology, which is applied to the preparation of salicylic acid functionalized graphene modified electrodes and the field of heavy metal detection, can solve the problems of difficulty in rapid detection, easy to be polluted, matrix interference, etc., and is beneficial to surface functionalization. The effect of modification, improved sensitivity, and lower detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Electrode preparation process

[0033] (1) Preparation of salicylic acid functionalized graphene modified electrode;

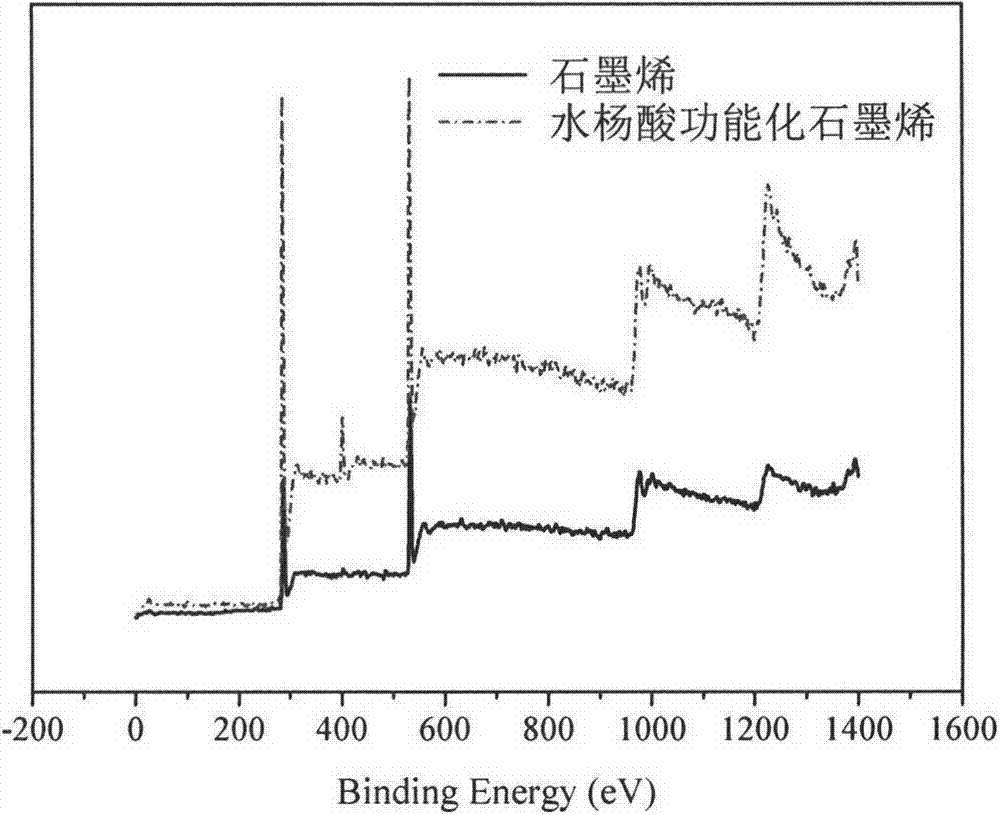

[0034] a. Preparation of graphene oxide by Hummer method

[0035] b. Take 100 mg of the above product and place it in a round bottom flask, add 600 mg of aminosalicylic acid and 100 mL of 0.01 M sodium hydroxide solution, reflux at 80°C for 24 hours. After the reaction, stand still and cool, the product is centrifuged, washed, and vacuum-dried to obtain salicylic acid functionalized graphene.

[0036] (2) The salicylic acid functionalized graphene was prepared into a 0.5 mg / mL solution by ultrasonic dispersion;

[0037] (3) Take 5 μL of the above solution and drop-coat it on the surface of the glassy carbon electrode polished to a mirror surface, the diameter of the glassy carbon electrode is 3 mm;

[0038] (4) The electrode was made into a working electrode after drying at room temperature.

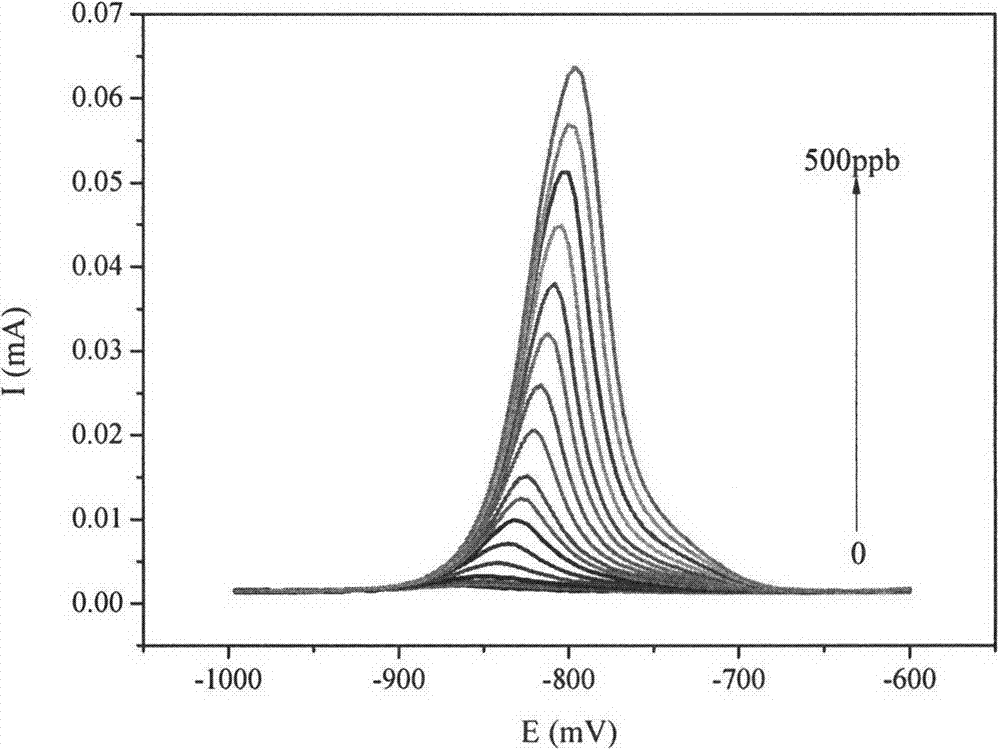

[0039] Detection process

[0040] (1) Test bottom fluid...

Embodiment 2

[0047] Electrode preparation process

[0048] (1) Preparation of salicylic acid functionalized graphene modified electrode;

[0049] a. Preparation of graphene oxide by Hummer method

[0050] b. Take 100 mg of the above product and place it in a round-bottomed flask, add 600 mg of aminosalicylic acid and 100 mL of 0.01 M sodium hydroxide solution, condense and reflux at 80° C. for 12 hours. After the reaction, stand still and cool, the product is centrifuged, washed, and vacuum-dried to obtain salicylic acid functionalized graphene.

[0051] (2) The salicylic acid functionalized graphene was prepared into a 1 mg / mL solution by ultrasonic dispersion;

[0052] (3) Take 5 μL of the above solution and drop-coat it on the surface of the glassy carbon electrode polished to a mirror surface, the diameter of the glassy carbon electrode is 2 mm;

[0053] (4) The electrode was made into a working electrode after drying at room temperature.

[0054] Detection process

[0055] (1) Te...

Embodiment 3

[0062] Electrode preparation process

[0063] (1) Preparation of salicylic acid functionalized graphene modified electrode;

[0064] a. Preparation of graphene oxide by Hummer method

[0065]b. Take 100 mg of the above product in a round-bottomed flask, add 300 mg of aminosalicylic acid and 100 mL of 0.01 M sodium hydroxide solution, condense and reflux at 80° C. for 24 hours. After the reaction, stand still and cool, the product is centrifuged, washed, and vacuum-dried to obtain salicylic acid functionalized graphene.

[0066] (2) The salicylic acid-functionalized graphene was prepared into a 0.2 mg / mL solution by ultrasonic dispersion;

[0067] (3) Take 10 μL of the above solution and drop-coat it on the surface of the glassy carbon electrode polished to a mirror surface, the diameter of the glassy carbon electrode is 4 mm;

[0068] (4) The electrode was made into a working electrode after drying at room temperature.

[0069] Detection process

[0070] (1) Test bottom l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com