Boiler capable of adjusting flue gas temperature of furnace outlet

A furnace outlet, flue gas temperature technology, applied in the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, etc., can solve the effect of boiler economy Larger problems, to achieve the effects of strong adaptability and adjustability, increasing dust area, and simple transformation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

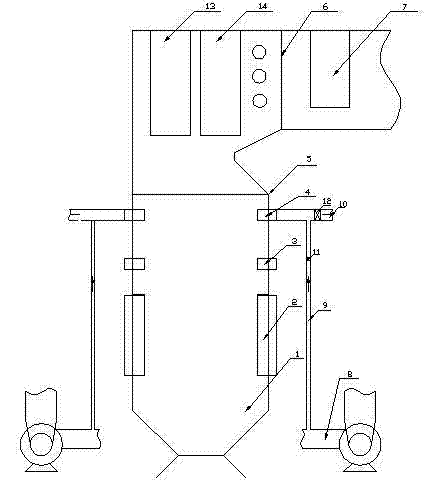

[0011] Example: such as figure 1 As shown, the boiler capable of adjusting the flue temperature at the furnace outlet includes a furnace 1, a furnace outlet 6 connected to the upper port of the furnace 1, a front screen superheater 13 installed in the furnace outlet 6, a rear screen superheater 14 and a high-temperature superheater 7 . Below the lower edge 5 of the flame angle in the furnace 1, namely the four corners of the middle part of the furnace 1, a burner group 2 is installed, and a remote type overburning air spout 3 is installed above the burner group 2, or the overburning air spout 3 may not be installed. At the four corners of the furnace 1 more than two meters above the type burn-off air spout 3, a temperature-regulating air spout 4 is installed. The height of the temperature-regulating air spout 4 is lower than the lower edge 5 of the refraction angle, and the lower edge 5 of the refraction angle is a known technology, and its specific position will not be descr...

Embodiment 2

[0014] Embodiment 2: as figure 1 As shown, another technical means of the present invention: arrange the tempering air nozzle 4 at the position before the furnace outlet 6, that is, between the rear panel superheater 14 and the high temperature superheater 7. At the same time, guide vanes are installed in the temperature-regulating air spout 4, and the guide vanes can rotate the air flow to strengthen the mixing with the flue gas. The guide vanes are in the form of typical swirl burners or oil burners. All the other are the same as in Example 1.

Embodiment 3

[0015] Embodiment 3: as figure 1 As shown, another technical means of the present invention: the temperature-regulating air nozzle 4 is arranged on the four furnace walls of the furnace 1 close to the lower edge of the refraction angle or two of them on the opposite furnace walls. All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com