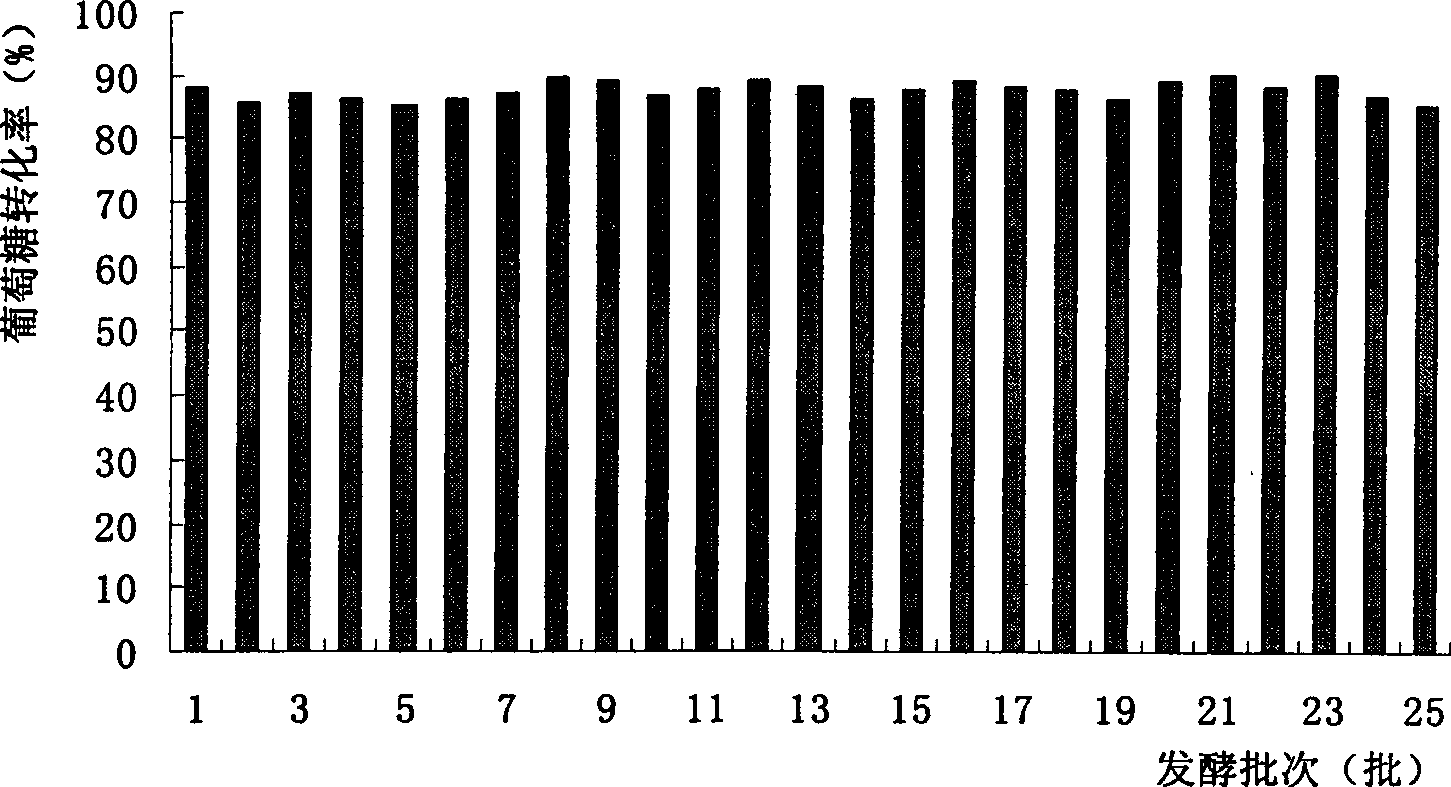

Novel technological process for producing high optical purity L-lactic acid by semi-continuous high-density fermentation of Rhizopus oryzae

A technology of high-density fermentation and optical purity, which is applied in the field of semi-continuous fermentation of Rhizopus oryzae to produce high optical purity L-lactic acid, which can solve the problems that the conversion rate of raw materials cannot be improved, the time of batch fermentation is prolonged, and the utilization time of bacteria is low. , to achieve high target yield and conversion rate of raw materials, shorten the time for multiplication and use, and facilitate automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The new process method of Rhizopus oryzae semi-continuous high-density fermentation to produce high optical purity L-lactic acid comprises the following steps:

[0040] (1) prepare Rhizopus oryzae spore suspension:

[0041] Use an inoculation loop to pick a loop of preserved Rhizopus oryzae 3.819 mycelium, inoculate it on a solid slope made of 50ml PDA medium in a 100ml Erlenmeyer flask, and cultivate it in a constant temperature incubator at 32°C for 72 hours to obtain mature rice roots containing One bottle of mycelium of mold spores, add 40ml sterile distilled water, beat mature rhizopus oryzae spores with a glass rod, and obtain mature rhizopus oryzae spores at a concentration of 5×10 10 ~10 11 / L of spore suspension.

[0042] The above-mentioned PDA medium is composed of the following substances in weight ratio: 200 g / L of potato, 20 g / L of glucose, and 20 g / L of agar.

[0043] (2) Preparation of high-density seed culture solution:

[0044] Inoculate 40ml of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com