Production method of L-phenylalanine

A technology of phenylalanine and a production method, which is applied in the field of bioengineering, can solve the problems of affecting the discharge efficiency of cell membrane permeability products, reducing the conversion rate of sugar and acid, reducing the stable period of bacteria, and accelerating the growth rate of bacteria. The effect of increasing the growth time of the body, improving the conversion rate of sugar and acid, and avoiding the waste of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The production method of L-phenylalanine uses Escherichia coli as the production bacterium, which is purchased from the Metabolic Engineering Laboratory of Tianjin University of Science and Technology. The specific implementation steps and methods are as follows:

[0026] In particular, the steps and methods described in this embodiment are applicable to all the following embodiments.

[0027] Strain activation: take the strain in the glycerol bacteria preservation tube and put it on the slant medium, use the inoculation loop to spread it evenly on the slant of the test tube, and incubate it at 37°C for 12 hours to form the first-generation seed; use the inoculation loop to take a loop of the first-generation seed, and put it on Homogenize the slant of the shaped bottle and incubate at 37°C for 12 hours at an inverted constant temperature to obtain the second-generation seeds.

[0028] Seed culture: use a 5L fermenter for seed culture, and the initial fermentation broth...

Embodiment 2

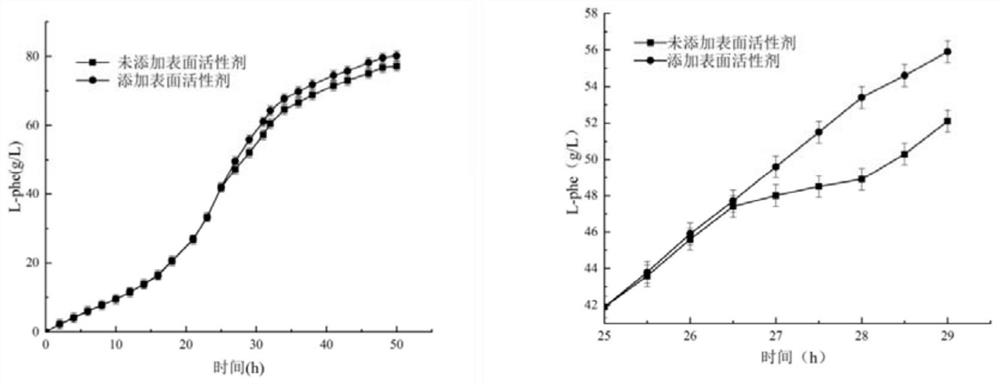

[0042] This part of the embodiment does not adopt the full nutrient fed-batch process, does not add biotin H, and only illustrates the impact of adding a defoamer (DX-09-2) on the output of L-phenylalanine, as figure 1 Shown:

[0043] When the L-phenylalanine in the fermentation broth reached 47g / L (26.5h), the acid production rate of the fermentation batch without adding DX-09-2 decreased significantly, and continued until 28h, and the acid production in 1.5h was 1.5g , and there was a lot of foam at this stage, and there were obvious crystalline substances in the fermentation broth sampled at 28h, so there would be a problem of acid production inhibition when it was close to the fermentation concentration; the fermentation batch with DX-09-2 added at 26.5h The occurrence of this problem is obviously avoided, the acid production efficiency in the crystallization stage is not significantly affected, and the total yield is increased by 3.9% compared with the fermentation batch ...

Embodiment 3

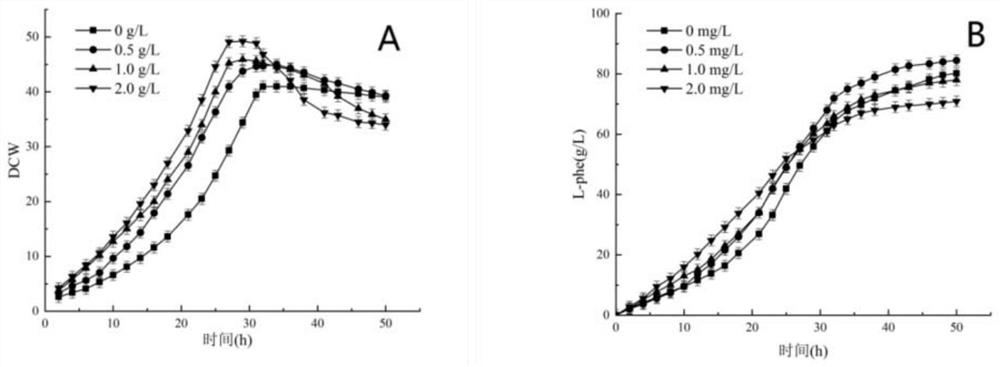

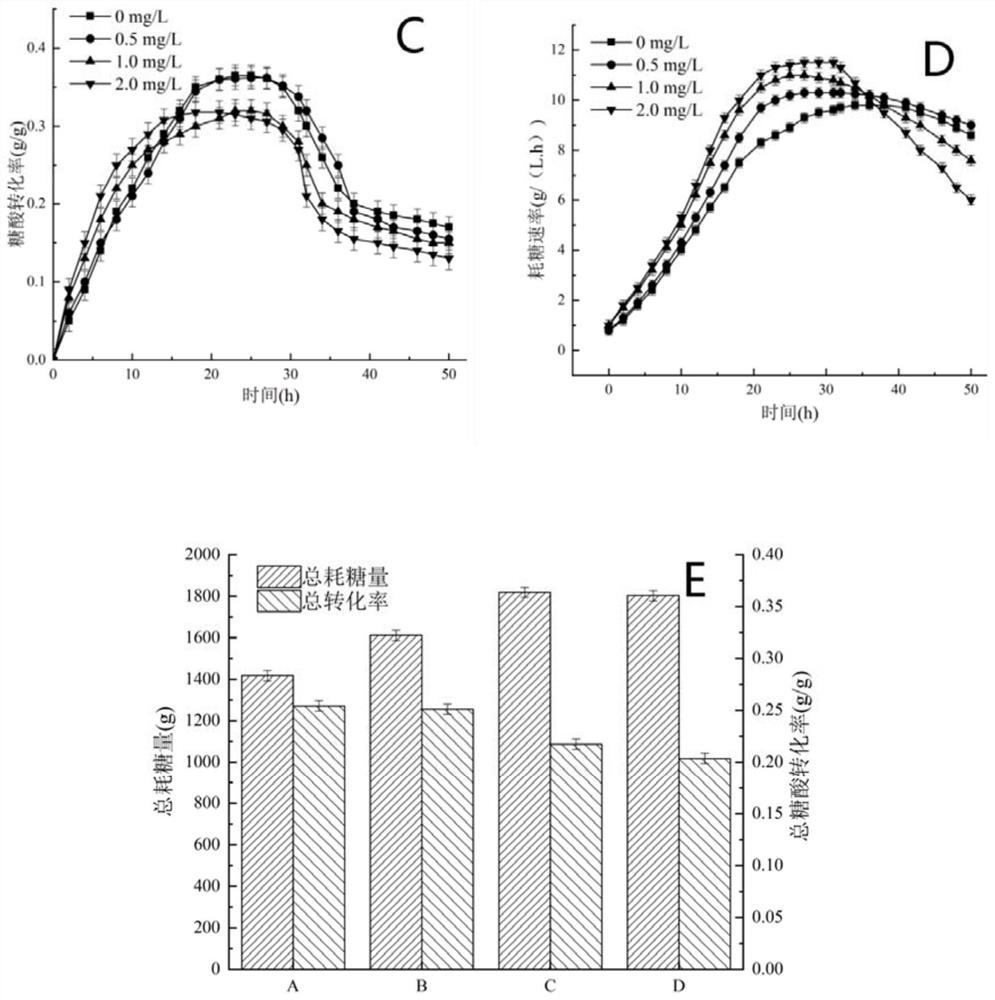

[0045] This part of the examples does not adopt the full nutrient fed-batch process. Under the premise of adding an antifoaming agent (DX-09-2) when L-phenylalanine is about to crystallize, the concentration of vitamin H in the fermentation medium affects the production of L-phenylalanine by fermentation. The effect of alanine is illustrated, the vitamin H concentration (mg / L) is 0, 0.5, 1 and 2, respectively, and the fermentation batch added with 0 mg / L is used as the control group.

[0046] Among them, the influence of the concentration of vitamin H in the fermentation medium on the amount of bacteria and the production of L-phenylalanine is as follows: figure 2 Shown:

[0047] The biomass of the control group reached the maximum value of 40.98g / L at 36h, and decreased at 38h. The biomass of the fermentation batch added with 0.5mg / L vitamin H reached the maximum value of 44.94g / L at 34h, and the biomass decreased at 36h. %. With the addition of higher concentrations of v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com