Method for recovering waste thermosetting resin and composite materials thereof through solvents

A composite material and thermosetting technology, which is applied in the field of chemical recycling of waste polymer materials, can solve the problems of high requirements for reaction equipment, unfavorable industrial applications, high temperature and pressure, etc., and achieves the effect of low price, low production cost and easy separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 100 parts of waste epoxy resin and 1 part of sodium hydroxide to 10 parts of polyethylene glycol, stir and mix evenly, then place in a kettle reactor, heat up to 200°C and react for 60 minutes, then filter to remove the obtained The solid phase product is separated from the liquid phase product, and the solid phase product is washed with water and dried; the liquid phase product is then added to the precipitant water (product volume: water volume = 1: 10), so that the insoluble degradation product and the soluble Solvent separation from water, and the solvent that can be dissolved in water is separated from it by conventional vacuum distillation.

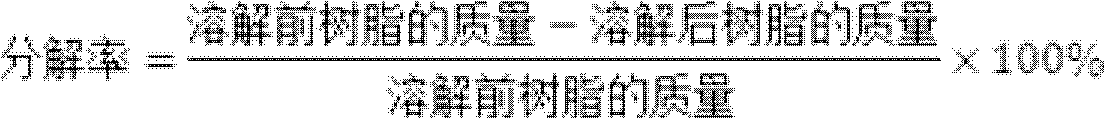

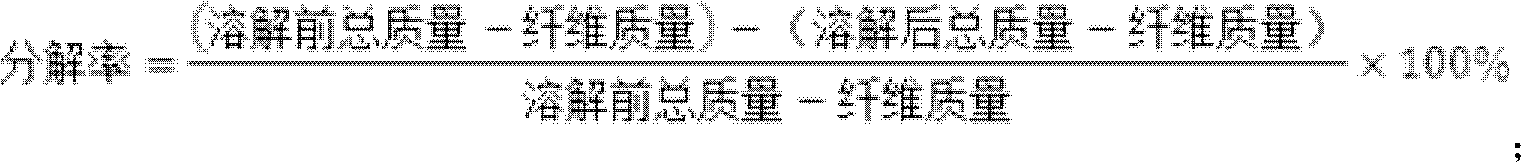

[0028] The resin decomposition rate of this embodiment is 80.23%.

Embodiment 2

[0030] Add 100 parts of waste phenolic resin to 200 parts of polyethylene glycol dimethyl ether, stir and mix evenly, then place it in a tank reactor, heat up to 150°C for 2.5 hours, and then filter the solid phase product obtained from the reaction with The liquid phase product is separated, and the solid phase product is washed with water and dried; the liquid phase product is then added to the precipitant water (product volume: water volume = 1: 10), so that the water-insoluble degradation product and the water-soluble solvent Separation, and the solvent that can be dissolved in water is separated with it by conventional vacuum distillation.

[0031] The resin decomposition rate of this embodiment is 75.87%.

Embodiment 3

[0033] Add 100 parts of waste epoxy resin, 1 part of sodium methoxide, and 5 parts of sodium hydroxide into 60 parts of polyglycerol, stir and mix evenly, then place in a microwave heating reactor, heat up to 60°C for 5 minutes, and then filter The solid phase product obtained by the reaction is separated from the liquid phase product, and the solid phase product is washed with water and dried; the liquid phase product is then added to precipitant water (product volume: water volume = 1: 10) to degrade the insoluble The product is separated from the water-soluble solvent, and the water-soluble solvent is separated from it by conventional vacuum distillation.

[0034] The resin decomposition rate of this embodiment is 88.43%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com