A Pneumatic Position Servo Controller Based on DSP

A servo controller, pneumatic position technology, applied in servo meter circuits, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of low integration, single communication mode, low intelligence, etc. Achieve the effect of accurate trajectory tracking, high control accuracy and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

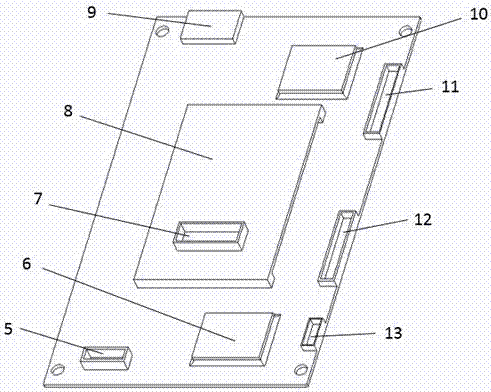

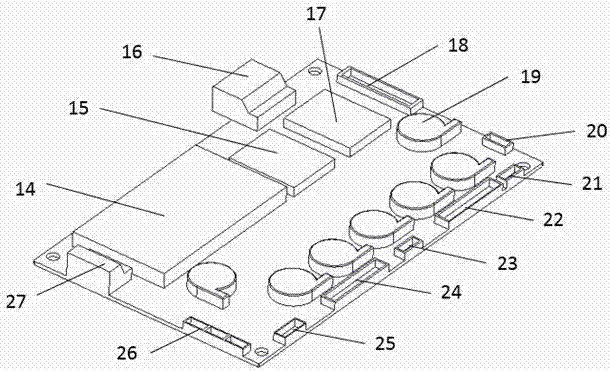

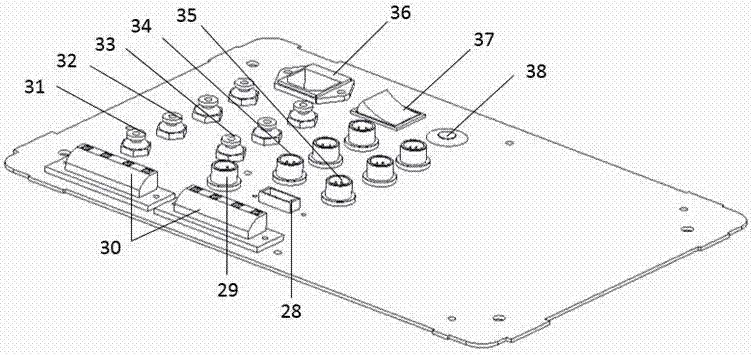

[0041] The present invention provides three groups of valve-controlled cylinder motion interfaces, and three identical control strategies are independently operated inside the DSP processor 8, and the control strategies do not interfere with each other, so they can be used for position tracking control at the same time, and can complete the control of a single cylinder. The position control and the three cylinders cooperate to control the pose of the platform. The control strategy adopts modern advanced adaptive robust control algorithm, which is a model-based control algorithm, and can identify system parameters when the program is running, with good control effect. The control algorithm is programmed in the program storage area of DSP. It can operate independently from the JTAG emulator interface; receive CAN bus data and commands during operation, and can send a stop command through the host computer to interrupt the operation of the controller during operation; limited by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com