Construction method of complex space truss integral hoisting system

A space truss and overall hoisting technology, which is applied in the processing of building materials, special data processing applications, design optimization/simulation, etc., to achieve the effect of meeting the installation space, ensuring accuracy, and ensuring installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

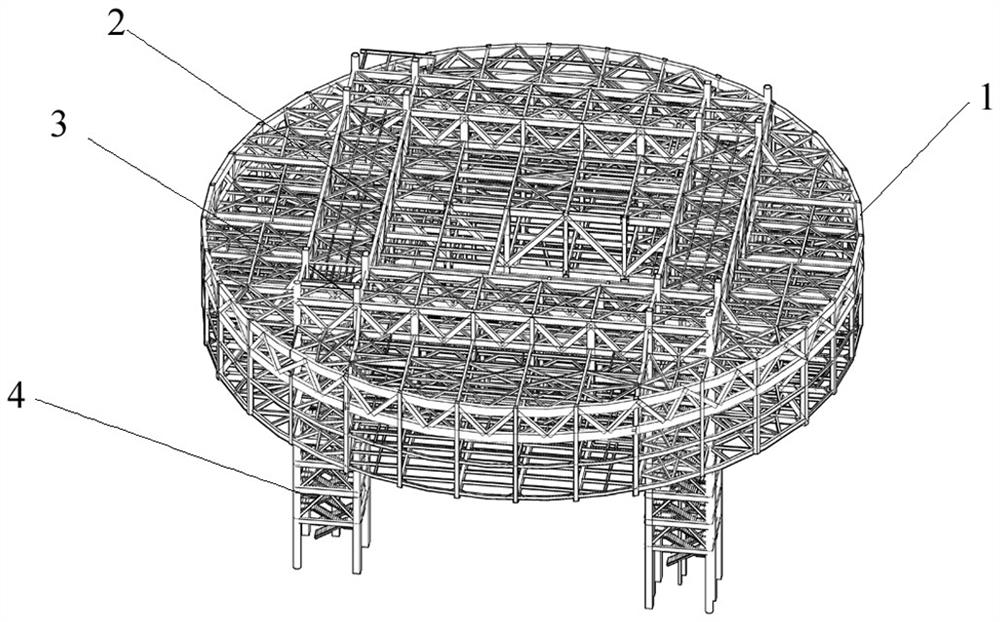

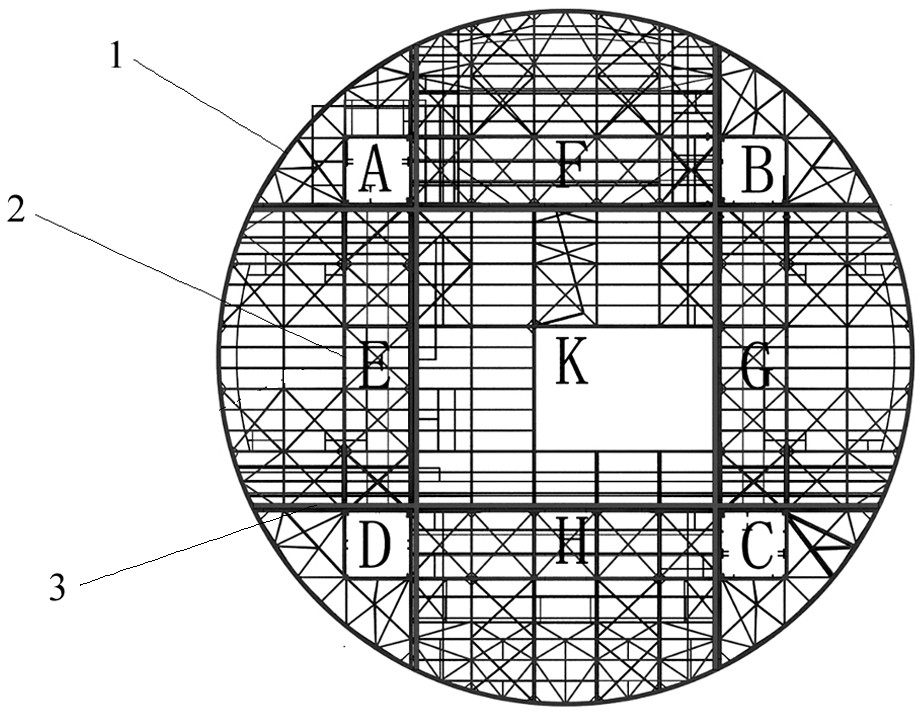

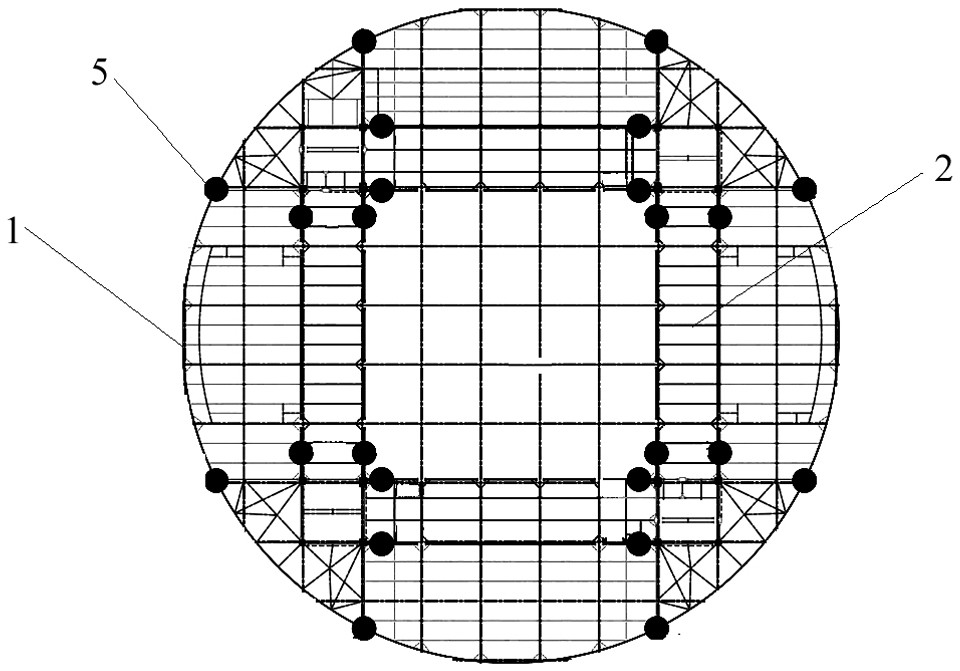

[0052] Taking a certain project as an example, the main building has 6 floors above ground and 1 floor underground (partly 2 floors underground); it mainly includes high-rise structures and corridor structures. Among them, the high-rise structure generally adopts a steel frame-support structure system, which is a space truss style; figure 1 As shown, the space truss includes a ring truss 1, a main truss 2 and a truss column 4, the ring truss 1 includes a plane truss and an arc truss, the space truss also includes a suspension frame, a buckling support, etc. Type, H type, round pipe, etc. The main structural materials are Q345GJ, Q345B, etc. The floor is mainly made of steel truss composite floor. The length of the corridor is about 200 meters, and the main components adopt box-shaped and H-shaped sections.

[0053] Such as Figure 1 to Figure 11 As shown, a complex space truss overall hoisting system includes an external ring truss 1, a main truss 2 connected inside the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com